OptiProERP Blogs

Insights, advice, tips and industry best practices for manufacturers and distributors

What Are The Benefits of a Product Configurator in Manufacturing?

April 15, 2024

For manufacturers that offer their customers configurable products or made-to-order products, a product configurator helps speed and streamline order processing. It also creates automated BOMs to ensure the product is manufactured according to customer specifications. In this blog, we will dive into what a product configurator is and how[...]

How to Track All Quote-to-Cash Steps to Produce a Final Product

April 10, 2024

From the moment a customer requests a quote to the final product delivery, a complex web of processes is in play. Managing these processes requires meticulous tracking from quote-to-cash (QTC). What is Quote-to-Cash? The quote-to-cash process encompasses every step, from the initial request for a quote to the receipt[...]

What is Extended Reality, and How Does It Affect Manufacturing?

February 14, 2024

Digital transformation is aggressively scaling up across all sectors of the manufacturing industry. Technologies such as Artificial Intelligence, Robotics, 3D printing, Virtual Reality, and Augmented Reality are transforming the manufacturing world. In this blog, we will learn about Extended Reality (XR), which is a superset of emerging technologies, such[...]

Additive Manufacturing and ERP: Enhancing Efficiency and Integration

February 9, 2024

Additive Manufacturing (AM), often called 3D printing, has emerged as a revolutionary technology potentially transforming traditional production processes. As this innovative approach gains traction across various industries, the need for seamless integration with Enterprise Resource Planning (ERP) systems becomes increasingly evident. This blog post will explore the intersection of[...]

ERP Security in Manufacturing: Safeguarding Data and Operations

January 19, 2024

In this tech-driven world, data is the driving force for every business, many of which use Enterprise Resource Planning (ERP) software. ERP software is a complete business management suite integrating data and business functions across sales, finance, accounting, purchasing, production, and other departments. Digital data stored in ERP gives[...]

How ERP Impacts Product Life Cycle Management

December 21, 2023

Enterprise Resource Planning (ERP) systems have evolved into indispensable business tools to streamline operations and enhance efficiency. Traditionally associated with functions such as finance, human resources, and supply chain management, ERP's profound impact on product management is often underestimated. There is an intricate relationship between ERP and the Product[...]

What Are the Differences Between Procurement and Purchasing in Manufacturing?

December 19, 2023

Acquiring goods from vendors and suppliers is one of the critical and routine tasks for manufacturers. Managing, planning, and tracking finance is very important when it comes to the outflow of cash. Otherwise, it can adversely affect a company’s bottom line. Procurement and purchasing are terms interchangeably used in[...]

Smart Manufacturing Trends to Expect in 2024

November 22, 2023

With 2024 on the horizon, more manufacturers are adopting smart manufacturing technology. It is helping them capture benefits across the entire manufacturing value chain. Key components of smart manufacturing include connected sensors and devices, data analytics and big data, AI, cloud computing, cyber security, digital twins, advanced robotics, blockchain,[...]

Why Sustainability is Becoming Critical for Manufacturers in 2024

November 15, 2023

In an era where environmental concerns are taking center stage, sustainability has emerged as a critical driver of success for manufacturers, big and small. Governments, consumers, and stakeholders increasingly prioritize sustainable practices, urging manufacturers to reevaluate their operations. While large corporations have been at the forefront of manufacturing sustainability[...]

Why Technology-Driven Manufacturing SMBs Outperform Their Peers

October 25, 2023

[vc_row][vc_column][vc_column_text]A recent study published by the US Chamber of Commerce noted that small businesses that utilize technology platforms outperform their competitors and are more optimistic about their future. Small businesses that use technology directly employ or support almost a billion jobs. Technology Use Is Linked to Growth and Optimism[...]

An Overview of Inventory Forecasting

September 22, 2023

Inventory forecasting, or demand forecasting, estimates future inventory levels needed using past data, upcoming events, and market trends. Inventory forecasting ensures manufacturers have the proper inventory to meet customers’ needs while minimizing excess inventory costs. It involves analyzing historical sales data and identifying patterns and trends to adapt to[...]

What Are Inventory Carrying Costs and How to Calculate Them

September 15, 2023

Inventory management is a critical aspect of any business that deals with physical goods. Keeping track of your inventory, ensuring you have the right amount of stock on hand, and minimizing costs associated with storing and managing inventory are all vital for a company's success. One essential component of[...]

Optimizing Production: The Art of Line Balancing

August 16, 2023

In the world of manufacturing, efficiency is the name of the game. Wasted time, resources, and materials can eat into profits and hinder growth. This is where line balancing comes into play - a strategic approach that can revolutionize your production line. Let's dive into the details of line[...]

OptiProERP’s Latest 2023 R2 Release: New Functionality for Container Management, Supply Chain Planning, and Estimation

August 8, 2023

2023 R2 OptiProERP has new features to help manufacturers make their day-to-day tasks easier and more efficient. Read further to learn the key functionality of this release. New Container Management Feature In the Container Management module, users can now enter a landed cost amount and distribute it to container[...]

How SMBs are Harnessing Powerful Data on Their Plant Floor

July 20, 2023

The manufacturing industry constantly strives for higher productivity, superior product quality, and cost optimization. In recent years, the rise of the "Smart Manufacturing" revolution has brought about unprecedented possibilities for manufacturers to achieve these goals successfully. At the core of this transformative wave lies the power of industrial Artificial[...]

How does the supply chain differ from the value chain?

June 23, 2023

In today's globalized and interconnected world, businesses operate in complex environments where efficiency, competitiveness, and customer satisfaction are paramount. To crucial frameworks help achieve these goals: the supply chain and the value chain. In this blog post, we will explore the significance of these interconnected systems and shed light[...]

Why ERP Implementations Fail and How to Ensure Yours Is Successful

June 19, 2023

Enterprise Resource Planning (ERP) systems are powerful tools that integrate various business processes into a unified system. ERP projects can benefit organizations significantly when implemented successfully through improved efficiency, streamlined operations, and better decision-making capabilities. However, the road to a successful ERP implementation is fraught with challenges, and many[...]

Creative Ways Manufacturers Can Overcome the Skilled Labor Shortage

May 18, 2023

The manufacturing labor shortage or skills gap is a major issue in the manufacturing industry. A labor shortage occurs when there is more need for labor than there are workers who can fulfill the requirement. To keep the industry moving forward, manufacturers must find ways to overcome this gap. [...]

8 Steps in the Procurement Process and How to Optimize Them

So what is procurement? Procurement is acquiring goods, services, or works from an external source. It involves sourcing, negotiation, ordering, delivery, and payment for goods or services. Procurement can be done by a government agency, a private organization, or an individual, and it can involve purchasing anything from pencils[...]

Critical Logistics KPIs Manufacturers and Distributors Should Track

April 25, 2023

[vc_row][vc_column][vc_column_text]You may ask yourself why KPIs are important. As a manufacturer, tracking logistics key performance indicators (KPIs) can help you identify areas of improvement and optimize your supply chain. However, with so many metrics to track, it can be overwhelming to know where to start. This blog post will[...]

7-Step Action Plan to Improve Delivery Performance

[vc_row][vc_column][vc_column_text]As a manufacturer, timely delivery of goods to customers is crucial for business success. Meeting delivery deadlines helps maintain customer satisfaction and repeat business, while poor delivery performance can lead to lost customers and a damaged reputation. Below are seven steps on how to improve delivery performance: 1. Streamline[...]

Industry 4.0 to Industry 5.0: Differences and Changes for Manufacturers

March 21, 2023

[vc_row][vc_column][vc_column_text]We live in an era where it is hard to imagine the manufacturing industry without robots, sensors, and computer-enabled software systems. But, before discussing the fifth industrial revolution, let’s brush up on the fourth industrial revolution or Industry 4.0. Powered by the Industrial Internet of Things, Industry 4.0 includes[...]

OptiProERP’s Latest 2023 R1 Release: New Container Management and CAPA Functionality

February 23, 2023

2023 R1 OptiProERP is now available with a new application and valuable features for more significant user benefits. Read on to learn the key features of this new release. New Container Management Application A new application, Container Management, will allow companies to manage shipping or receiving containers. Container management[...]

SAP Business One – What’s Coming for 2023

February 2, 2023

[vc_row][vc_column][vc_column_text]SAP Business One, in which OptiProERP is natively embedded, is fully invested in improvements for 2023 that will provide many valuable new features. Rainer Zinow, Senior Vice President and Head of SAP Midmarket Product Management, created his annual video outlining the SAP Business One Road Map and planned enhancements.[...]

The Difference Between Configuration and Customization in ERP Implementation

January 25, 2023

[vc_row][vc_column][vc_column_text]If you are looking for an ERP system that aligns with your business requirements, you will likely come across customization and configuration terms. Although customization and configuration seem to be similar concepts, they have different meanings and purposes. The critical difference is the scope of work, time, cost, and[...]

9 Critical ERP Features for Discrete Manufacturers

January 17, 2023

Manufacturers need specific functionality to run their businesses effectively. When looking for a solution, you need to find ERP software with features that will fully optimize your business to compete and grow. Let’s examine what ERP functionality is critical for discrete manufacturers. (more…)

6 Difficulties Faced by Industrial Machinery Manufacturers That ERP Solves

December 13, 2022

[vc_row][vc_column][vc_column_text]The past two years have been a roller coaster ride for most industries. We have witnessed challenged supply chains, scrambled logistics networks, global health crises, unemployment, and much more. Although we have entered into the new normal, the pandemic has brought several operational challenges to the manufacturing industry (State[...]

7 Challenges ERP Helps Electronics Manufacturers Overcome

December 9, 2022

[vc_row][vc_column][vc_column_text]The electronics industry changes at a fast pace with constant innovations. Electronics are used in consumers’ everyday lives, both at work and at home. Electronics manufacturers have many revenue opportunities, but also many challenges to overcome to be competitive. Electronics manufacturers must adapt to many emerging trends. They need[...]

7 Top Concerns for CFOs in 2023

November 23, 2022

[vc_row][vc_column][vc_column_text]The CFO’s role, in part, is to determine a company’s financial strengths and weaknesses and help make smart strategic decisions based on that analysis. They also have to consider the upcoming economic climate and how that will impact business. For CFOs in smaller companies, their responsibilities are likely to[...]

2023 Manufacturing Trends: How to Get Ready Now

November 21, 2022

2022 has proven to be both positive and disruptive for the manufacturing industry. Despite the pandemic, recession fears, supply challenges, a tight labor market, and economic instability, manufacturing companies continue to survive and evolve in the “new normal.” In 2022, Industry 4.0 helped transform many manufacturing businesses. Industry 4.0[...]

8 Manufacturing ERP Use Cases That Can Help Your ERP Decision

November 3, 2022

[vc_row][vc_column][vc_column_text]It’s difficult to determine if an Enterprise Resource Planning (ERP) system is right for your business. It provides many advantages, including a unified database with integration across departments. Implementing an ERP can provide a significant return on investment due to factors such as business intelligence and efficiency gains. Manufacturers[...]

Trends, Impacts, and Benefits of Industrial Connectivity for Shop Floor Machines

October 26, 2022

[vc_row][vc_column][vc_column_text]Remote monitoring and control of machines are growing, and according to Research and Markets, it should reach $31.7 Billion by 2026, up from $23 Billion in 2020. Companies are adopting remote connectivity for many reasons, including technology that makes it more accessible and less expensive and the need to[...]

How Can Manufacturers Build Resilience and Become Sustainable?

[vc_row][vc_column][vc_column_text]Did you know: 90% of manufacturing leaders see a positive relationship between their performance and the sustainability transformation of their organization? 84% of consumers claim sustainability is a key consideration when making a purchase decision? 62% of global Co2 emissions come from manufacturing sectors? 54% of global energy consumption[...]

7 Ways to Reduce Manufacturing Costs Without Sacrificing Quality

September 22, 2022

[vc_row][vc_column][vc_column_text]Saving on operational costs is one of the biggest goals for manufacturing companies. Most manufacturers look to streamline systems, reduce production costs, and increase profitability without sacrificing product quality. Often, the quickest and easiest way to cut costs is by accepting minimum quality levels or reducing employees. This can[...]

The Differences Between Job and Process Costing and How to Keep Both Profitable

September 21, 2022

[vc_row][vc_column][vc_column_text] What is Job Costing? Job Costing is how much it costs to complete a job. It is used in manufacturing for custom orders. Getting job costing right is key to knowing how much to charge a customer and make a fair profit. How Do You Calculate Job Costs?[...]

OptiProERP July 2022 R2 Release – New WMS Enhancements

August 24, 2022

We recently came out with a new product release that includes two Warehouse Management System (WMS) mobile functions using the WMS scan feature that will make inventory counting easier. The first is Spot Count which allows spot or ad-hoc counting to be done for unscheduled inventory counting requirements on[...]

7 Proven Methods to Increase Manufacturing Throughput

August 19, 2022

What is Throughput? Throughput is the time it takes for a product to pass through manufacturing processes on a machine-by-machine basis for a defined period. Throughput only includes fully completed work and none that is still in progress. Throughput is an essential KPI, and a lean metric, as it evaluates performance.[...]

The 12 Most Important KPIs for Manufacturing Production

August 18, 2022

[vc_row][vc_column][vc_column_text]What’s covered in this blog: What KPIs are in manufacturing The difference between KPIs and metrics What determines a good KPI Why manufacturers should use KPIs The top 12 manufacturing KPIs and how to calculate them How KPIs can be made actionable Manufacturing KPIs are quantifiable measures of production[...]

6 Reasons Why ERP Systems Are Critical for Unified Business Insight

June 14, 2022

In today’s dynamic manufacturing environment, achieving operational excellence is essential. With rapid technological advancement and heightened consumer expectations, manufacturers must adopt innovative solutions to gain a competitive edge. Why is There a Need for ERP in a Business? Enterprise Resource Planning (ERP) is an indispensable tool that helps manufacturers[...]

Manufacturing SMBs Achieve Greater Control with ERP vs. Disparate Systems

[vc_row][vc_column][vc_column_text]As your company grows, you must put more effort into streamlining your business operations to sustain growth. When data is stored in disparate systems, it can create significant challenges for businesses. Managing different functions such as accounting, purchasing, sales, HR, customer relations, and the supply chain is difficult on[...]

How to Modernize Your Supply Chain to Ensure On-time Deliveries

May 24, 2022

Supply chains have been disrupted for over two years now, beginning with the pandemic and, most recently, international conflicts. Having supplies delayed can wreak havoc on manufacturers, resulting in slowed production, delayed shipments, and unhappy customers. Without a way to proactively mitigate supply chain issues, manufacturers risk losing their[...]

4 Hidden Costs of Using Outdated Technology Amid the Digital World

May 23, 2022

In the words of Henry Ford: “If you always do what you always did, you’ll always get what you always got.” The manufacturing sector is becoming increasingly efficient, modular, automated, and customized. Manufacturers that embrace new technology are much more likely to reach their full potential. But manufacturers are[...]

How Advanced Planning and Scheduling Helps Manufacturers Streamline Production

April 19, 2022

30 Second Summary APS synchronizes thousands of resources to create accurate production schedules It lets you react fast to market changes and deviations in production It provides quick ROI through lower costs and increased efficiencies Using finite and infinite capacity you can plan for various time horizons Keeping production[...]

5 Ways an Industrial Machinery Manufacturer Transformed Their Shop Floor

April 18, 2022

The shop floor is the cornerstone of the manufacturing process. It is the place where machines are set up for production, parts are assembled, raw material is processed, and operations are scheduled. When well managed, the shop floor works at optimal capacity and with operational efficiency. In this blog,[...]

How SMBs Receive Substantial ROI from Cloud ERP

March 24, 2022

Some form of cloud technology is used by 69% of businesses according to a study by the International Data Group. Much of today’s business operations depend on the power of cloud solutions. More and more SMBs are adopting cloud ERP to handle their business operations due to its fast implementation,[...]

4 Key Inventory Control Issues to Solve for Increased Margins

March 17, 2022

Inventory is something many businesses struggle to manage effectively. Not having control over inventory can be a significant problem that can cause a company to close its doors or struggle with debt. That’s why it’s considered one of the top four problems in the manufacturing industry. When you don’t[...]

5 Key Things You Should Know About Safety In the Cloud

March 16, 2022

30-Second Summary Cloud computing is the future. It is the foundation of digital transformation. Cloud ensures data security by storing datasets on robust and encrypted datacenters. How can you ensure the information you stored on cloud servers is safe? This blog explains 5 things you should know about safety[...]

Juggle Better: 6 Ways Production Scheduling in ERP Helps Manufacturers

March 14, 2022

Before getting into production scheduling and how it helps manufacturers, let’s have a quick look at the functions of the production department in a manufacturing organization. The production department transforms raw materials into finished goods. It can include technicians, designers, engineers, machine operators, and more. Production scheduling is the[...]

ERP System Price: Breaking Down ERP Software Costs

December 28, 2021

Trying to select an ERP system is complicated and so is comparing pricing. That’s because there are so many variables that affect the cost. If you want to determine if your business can afford an ERP system, remember to take into account the ROI it will provide as well as[...]

The Progression Leading to Industry 4.0

November 19, 2021

Innovations have brought about some significant milestones to industries over the years. In 1765 the first industrial revolution began when the use of coal and steam engines became popular allowing for the transportation of goods using railroads. Mechanization also became widespread and the United States became more focused on[...]

How ERP Helps Businesses Accelerate Digital Transformation

October 26, 2021

Digital transformation is the integration of innovative digital technologies into all areas of a business to improve the customer experience and core operations. It’s about finding new ways to generate value and promote overall business efficiency. There are many ways in which manufacturing companies can adopt digital transformation. For[...]

What Is Digital Transformation and Can It Benefit Manufacturers?

October 21, 2021

The manufacturing industry is constantly changing and is often at the forefront of utilizing new technologies. For example, many manufacturers are now using Industry 5.0 technology to help assist workers on the plant floor. And others still struggle with manual processes, QuickBooks, Excel spreadsheets, and maybe a poorly integrated[...]

Is It Time to Replace Your Legacy ERP With a Modern Cloud ERP?

October 1, 2021

Is your current ERP system up-to-date with the needs of your business today and into the future? If you’ve been using a legacy ERP system for decades, it’s likely your business is compromised. Your current business management software should be more powerful and capable than the system you used a[...]

Cloud ERP vs. On-Premise ERP

Companies are not only acknowledging the advantages of effective ERP systems, they’re also increasingly adopting these solutions such that the market will be worth $60.23 billion by 2026. Advanced technology, AI, data analytics, IoT, and global competition have collectively engineered the need for more transparent business processes. They have[...]

Understanding ERP Modules and Their Business Benefits

September 10, 2021

[vc_row][vc_column][vc_column_text]Gone are those days when growing companies used to manage their data on spreadsheets. Modern businesses rely on Enterprise Resource Planning (ERP) software to help them collect and organize financial and operational data in a shared database to promote efficiency, as they scale. From providing accurate, real-time information to[...]

The Essential 5 Steps to Selecting the Right ERP System for Manufacturers

June 4, 2021

It’s more important than ever for manufacturers to find ways to effectively manage their operations in the face of Covid-19, supply chain disruptions, inflation concerns, glimpses of recovery, and the many dynamics impacting manufacturers’ bottom lines. A survey from the Institute for Supply Management shows almost 75% of organizations[...]

ERP Software Selection: 6 Things to Consider for Supply Chain Management

May 3, 2021

[vc_row][vc_column][vc_column_text]Enterprise Resource Planning (ERP) solutions are now a dime a dozen. It’s for this reason that careful attention is needed when selecting the right ERP software for your specific business requirements. That includes your supply chain management needs, such as managing your suppliers and vendors, purchasing or supplying material[...]

How AI and ML Will Enhance ERP and Its Impact

May 14, 2020

Scenarios in which the entire production cycle is managed with just a few clicks and taps and are not limited to science fiction movies anymore. As per a study by Gartner, 37% of organizations have implemented Artificial Intelligence (AI) solutions in one form or another. Digital disruption has led companies[...]

8 Ways That Cloud ERP Helps Manufacturers Create Value with Exception Management

January 29, 2020

[vc_row][vc_column][vc_column_text]Cloud ERP creates value by saving time and resources with exception management. Management principles often focus on optimizing a system. Exception management is focused on preventing problems before they occur. What is Exception Management? Let's start with a definition of exception management. It is a type of process management[...]

Delivering a Best-in-Class Customer Experience with Cloud ERP

January 8, 2020

This blog is part of a three-part series on how cloud ERP enables manufacturers to achieve operational excellence. In the series, we also cover how cloud ERP helps manufacturers improve cash flow by providing accounting visibility and drive companywide value through adoption and digitization. These topics and more are[...]

How Accounting Visibility from Cloud ERP Improves Cash Flow

This blog is part of a three-part series on how cloud ERP enables manufacturers to achieve operational excellence. In the series, we also cover how cloud ERP helps manufacturers deliver a best-in-class customer experience and drive companywide value through adoption and digitization. These topics and more are covered in[...]

4 Steps to Value Creation with Intelligent Cloud ERP for Manufacturers

December 23, 2019

The OptiProERP team is constantly reading and sharing industry articles so we can point out those of particular value to you. This piece from SAP, "The Definitive Guide to Value Creation with Intelligent Cloud ERP," is an informative read and well worth your time. Here’s why. Value Creation Defined[...]

How Shop Floor Execution Software Supports a Customer-first Focus

November 14, 2019

Many small and mid-size manufacturing businesses think of shop floor operations as an internal-facing process. As a result, the tendency is to view their shop floor planning software (SFES) as only a tool to drive internal value using its ability to control, monitor, and measure shop floor efficiency. But the shop[...]

The Jump from QuickBooks to ERP Accounting: What Management Needs to Know – Part 4 ERP Analytics/Reporting and Finance Control

October 21, 2019

By: Allan Lessing, Director of Customer Success Part 4: ERP Analytics/Reporting and Finance Control As I finish up this series of blogs, I want to encourage managers at new, small, and midsize businesses to start to look beyond QuickBooks to ERP accounting and financial functionality. It’s time for ERP[...]

The Jump from QuickBooks to ERP Accounting: What Management Needs to Know – Part 3 Competitive Advantages of a Single ERP Platform

By: Allan Lessing, Director of Customer Success Part 3: Competitive Advantages of a Single ERP Platform Management at small and midsize manufacturing companies are cautious and risk adverse when it comes to employing new technology and changing to a new process. But reliance on QuickBooks and other stand-alone solutions[...]

The Jump from QuickBooks to ERP Accounting: What Management Needs to Know – Part 2 ERP Benefits and Value of the Cloud

By: Allan Lessing, Director of Customer Success Part 2: ERP Benefits and Value of the Cloud We are constantly monitoring what managers want to know as their companies consider moving from QuickBooks to ERP for accounting and financials. It’s almost an inevitable step as companies grow, add more transactions,[...]

The Jump from QuickBooks to ERP Accounting: What Management Needs to Know – Part 1 Growth and Business Needs

October 17, 2019

By: Allan Lessing, Director of Customer Success Part 1: Growth and Business Needs Throughout my career, I’ve seen it countless times. Managers of growing small to midsize manufacturing businesses find that the capacity of their start-up applications often falls short. They need to make the strategic jump to more[...]

SAP Ranked No. 1 ERP Solution – What It Means for Us and Our Customers

September 13, 2019

I’m excited and proud to announce that SAP, with whom we have a strategic partnership, has been ranked No. 1 ERP software by revenue for the second consecutive year. The #1 ranking was reported in Gartner’s Market Share Analysis: ERP Software Worldwide, 2018. As SAP’s strategic industry partner for[...]

What is Production Planning and Control, Its Benefits and Steps?

September 11, 2019

[vc_row][vc_column][vc_column_text]Production planning and control manages and schedules the allocation of human resources, raw materials, work centers, machinery, and production processes. It finds the most efficient way to produce finished goods with the lead times needed to meet production demand. Production planning and control are two strategies that work cohesively in[...]

5 Ways ERP and MES Integration Makes Manufacturers Agile

August 27, 2019

[vc_row][vc_column][vc_column_text]In our last blog post, we explored the differences between Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) and how together they help provide operational clarity. In this post, we’ll explore how ERP and MES integration can make your manufacturing business more agile. MES software focuses on all[...]

Machine Learning Use Cases in Manufacturing

July 8, 2019

To understand how machine learning will impact manufacturing, it’s first useful to understand what the term means. Machine learning is a type of artificial intelligence where computers leverage new information to automatically improve their outputs. Machine learning is no longer limited to just mobile phones or game shows. When[...]

Top Reasons to Use an ERP System for Accounting

July 3, 2019

I know you’re already accustomed to using your favorite accounting software that stores your company’s financial data. But the problem most manufacturers face is that this software is limited to providing accounting solutions alone and in no way aid in streamlining your other everyday business processes. You need to[...]

ROI of an ERP System: What Returns to Expect From a Manufacturing ERP Investment

June 18, 2019

The decision to implement or upgrade an ERP solution can help take your business to the next level. A modern ERP solution reduces operating costs, increases productivity, and offers standard features that automate business tasks and save time. Investing an extensive amount of money in ERP is a big[...]

5 Ways ERP Improves Inventory Visibility

What is inventory visibility? Simply put, inventory visibility is knowing how much inventory is available, at what location, and at any given point in time. Whether in transit, in a warehouse, or distribution centers, you need to know inventory levels at all locations. What are the benefits of inventory visibility? 1. More[...]

Forecasting made easy for manufacturers with intelligent ERP software

June 4, 2019

Predicting future demand contributes to making well-informed organizational decisions. Forecasting helps businesses plan for future endeavors by evaluating historical data and analyzing trend patterns. It is the process of extracting information from past and present data to make diligent decisions regarding purchase, sale, inventory and other departments. Before planning[...]

How Manufacturing ERP Scales-up Productivity and Reduces Costs?

May 22, 2019

In today’s high-tech world, all manufacturing businesses strive to stay ahead of the competition and handle growth driven by customer demands. To gain customer loyalty, you need to have the right processes in place. This is achieved with the technology that enables your business: technology that’s affordable on a[...]

ABC Analysis of Inventory: Optimize Business Bottom Line

May 20, 2019

The most common concern supply chain management experts struggle with is accurately identifying the causes of inventory inconsistencies. If a discrepancy is identified when users pick an item or perform a count, an inventory correction needs to be performed. Every inventory issue has a specific method that can be[...]

Maximize Operational Efficiency with Smart Manufacturing

May 15, 2019

Manufacturing businesses demand versatility, adaptability, and resourcefulness. In this tech-savvy world, every small and large-scale organization needs to gain greater visibility of data and operations so that processes are streamlined and time is efficiently used. Smart manufacturing is a broad term that means modern technologies like IoT, Artificial Intelligence, Machine Learning,[...]

What is Material Requirements Planning and Manufacturing Resource Planning Software?

May 1, 2019

Manufacturing companies convert raw materials into a form that is of more value and use for the consumer. Developed in the 60s and 70s, material requirements planning (MRP) offered an important breakthrough for shop floor managers. It linked production plans for finished goods with the requirements for the parts[...]

OptiProERP: The ‘Rising Star’ Manufacturing Business Solution

April 17, 2019

OptiProERP, a modern and end-to-end ERP solution for manufacturing and distribution has been awarded the Great User Experience and Rising Star awards by FinancesOnline, an independent software review platform. FinancesOnline’s team of experts evaluated OptiProERP with a total rating of 8.0/10 after a run of their internal tests. FinancesOnline research concluded that the actual[...]

MRP vs MRP II vs ERP: An Introduction for Manufacturers

April 10, 2019

[vc_row][vc_column][vc_column_text]Manufacturing is complex. There are many tasks involved in the manufacturing process, from maintaining accurate stock levels to controlling production functions. Manufacturers used to manually plan production and manage purchasing activities. That was before computers dominated the industry. But today there are software solutions available to help handle these[...]

What Is MRP? Why Is It Important for Manufacturing Businesses?

March 27, 2019

Recently OptiProERP attended an international exhibition about manufacturers. Our marketing executive met Harper Sheldon, operations head of a leading manufacturing company and one of our loyal customers during the event. Mr. Sheldon shared his experiences stating the importance of MRP for manufacturing businesses. Read some of what he shared:[...]

Is Intelligent ERP Right for Me?

March 21, 2019

Digital Transformation Is Sneaking up on You! I received a bit of a shock on the September 27th , 2018. I discovered it was Google’s 20th Birthday! You see, I have been in the IT industry for more than twice as long as Google has existed, and yet I[...]

What Does Intelligent ERP Do?

March 20, 2019

The possibilities are endless with digital transformation, limited only by an ability to think about your business – what you do, how you do it, how you could do it better, quicker or smarter. In our blog, “What is Intelligent ERP?”, we looked at the enablers of digital business:[...]

What is Intelligent ERP?

March 4, 2019

You may have heard about Intelligent ERP (Enterprise Resource Planning), but what is it? In two words, CONNECTIVITY and ACCESS. IDC defines Intelligent ERP as ERP applications or suites that use machine learning and advanced analytics built on a large, curated data set to forecast, track, learn, route, analyze,[...]

5 Key Benefits of ERP for Accounting and Financial Management

February 26, 2019

[vc_row][vc_column][vc_column_text]Enterprise Resource Planning (ERP) software has become an inevitable part of modern businesses. It provides business functionalities that are designed to address inventory requirements, the quality of finished products, productivity, and visibility to crucial business processes. The benefits of ERP systems are many, but how does it benefit the accounting and financial management[...]

5 Main Differences Between ERP and Accounting Software

Accounting software typically covers the management of areas such as financial reporting, accounts payables and receivables, banking, and recording of basic revenues/sales ERP solutions include multiple modules with accounting being one of them. Other modules include supply chain, planning, inventory management, warehouse management, production, HR, sales, purchasing, and more. However, many people use the terms “accounting software” and[...]

What is Manufacturing ERP?

January 25, 2019

What distinguishes Manufacturing ERP from other ERP systems? We are all familiar with what ERP systems are: One software solution that brings all core business processes into one database and system, eliminating ‘silos of information’ and separate applications for various departments. They operate in real time, and have a[...]

How OptiProERP Integrates SAP Business One With Magento

January 17, 2019

Transformation depends on the way businesses satiate the needs of their valuable customers. Understanding how to do it is a big task. Right now, e-commerce is booming. Online business has taken a great jump and this has encouraged usability of open source e-commerce software like Magento and Opencart. If[...]

How Does a Manufacturer Automate Logistics Operation in Their Warehouse?

January 15, 2019

Envision an automated forklift running down an aisle, stacking inventory into huge racks that tower 60 feet above the floor of your warehouse. Or an auto-guided robot that processes orders of up to 3,500 picks per hour! Could this be a warehouse of the 22nd century? Well, you don’t[...]

Why Small Manufacturing Businesses Need More Than Accounting Software

January 8, 2019

Here’s what you need to know 6 min read… If you are a SMB that plans to grow, you need more than just accounting software! Our business strategist Emily Bronte explains why. Have you ever felt while managing business processes that you were spinning plates while riding a unicycle?[...]

Tips and Warnings for Implementing an ERP System

December 28, 2018

Back when I was virtually full-time working with clients on ERP implementations, I had a trick that seemed to work to overcome many of the issues around keeping a project on track and on budget. I would take the entire plan, all the steps, and put them in a[...]

What Are the Benefits of Upgrading ERP Software?

December 26, 2018

In today’s tech-driven world, manufacturers embrace rapidly evolving technology to remain competitive and protect critical business data. If you’re working on an outdated version of your ERP, you may be considering an upgrade to the latest version. To make the decision to invest in an ERP upgrade, let’s look[...]

What Are Some Cutting-edge Developments in Connected Manufacturing?

December 24, 2018

Digital transformations are driving the manufacturing industry on a moment-to-moment basis. Just the way the industrial revolution impacted manufacturing, the digital transformations worldwide are responsible for changing the industry. Now most manufacturers are using technologies that are moving mass production to customized production, and this too is happening at[...]

7 Key Manufacturing Trends to Watch in 2022

December 13, 2018

Since the beginning of the Industrial Revolution, manufacturing has been the force that has pushed industrial and societal transformations forward. Today, we’re amid another industrial revolution, as a new generation of sophisticated technologies is transforming manufacturing into a highly connected, intelligent, and ultimately, more productive industry. The man-powered shop[...]

Demystifying cloud computing for small and midsize businesses

December 12, 2018

"Cloud computing is a great euphemism for centralization of computer services under one server.” – Evgeny Morozov, author and technology skeptic Do you use cloud technology in your business? If your answer is a ‘yes’, you are one of the many tech-savvy businesses. And, if your answer is a[...]

The price and intelligence of business applications in the cloud

December 7, 2018

Cloud computing is a prevalent buzzword among businesses and technology professionals. The real question for many IT technologists is whether the cost of transitioning to cloud applications will be low enough to have a significant ROI? Or will it be more costly to delay this investment? The benefits of[...]

Agile Manufacturing vs Lean Manufacturing

November 30, 2018

Lean and Agile are two of the most commonly discussed and debated principles of manufacturing, particularly when there’s a transformation underway. While there are many similarities between the two, manufacturers need to have a clear understanding of how and when to put them into practice. If you look close,[...]

What Is the Difference Between Manufacturing and Fabrication?

November 27, 2018

After a busy and productive week, you get an urgent call from a client. They have a rush job and need it completed right away. The manufacturing unit operates over the weekend, but you need to add an additional shift to meet the deadline. Now imagine, with all details[...]

How Much Does a Typical Implementation Cost?

November 21, 2018

Achieving extraordinary business transformation through the implementation of an ERP solution isn’t a matter of luck. It requires careful planning and a commitment to the best practices of quality. To establish predictability and transparency in your project, whether you are intending to implement an on-premise or a cloud solution,[...]

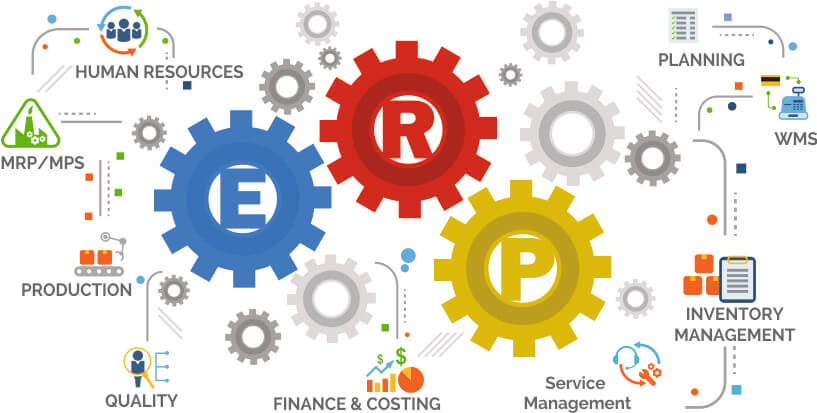

Basic Modules of an ERP Solution in the Manufacturing Sector

November 16, 2018

ERP software provides some of the most up-to-date modules for manufacturing businesses today. ERP modules help you meet the requirements of the manufacturing industry by creating a complete production scenario including routings and bills of materials. It also makes it easy to manage finances and costing by generating a[...]

What Are the Benefits of ERP in the Manufacturing Industry

November 14, 2018

The manufacturing sector has gone through a massive overhaul. Sought-after manufacturing practices encourage information mobility, growth management, and enhanced productivity. Fortunately, with best-of-breed software solutions, it has become possible for employees to work collaboratively, no matter where they are, and irrespective of the time. Manufacturers are now investing in[...]

What is a Manufacturing Execution System (MES)?

October 29, 2018

A Manufacturing Execution System (MES) is an information system that connects, monitors and controls complex manufacturing systems and data flows on the shop floor. The main goal of an MES is to ensure the effective execution of manufacturing operations and to improve production output. An MES helps achieve that[...]

How Cloud ERP is Transforming Manufacturing Businesses

October 26, 2018

What is Cloud ERP? Cloud computing has fundamentally changed the way organizations work. As long as your data resides in the cloud it is always easily accessible. If we had to define it at its most basic level, ERP software links all the business processes from procurement to sales,[...]

How Can ERP – Help Apparel Manufacturers Save Time and Money?

October 23, 2018

The textile and apparel industry is one of the most dynamic and crucial industries across the world that was worth approximately $3,000 trillion in the year 2015 – including clothing, footwear, textile, and luxury fashion. From manufacturing and designing clothes to distribution and use of manufactured textile, every operation[...]

ERP Implementation: Steps and Best Practices

October 18, 2018

Once you have selected ERP software for your organization, the next step is ERP implementation. Implementing ERP software is quite a complex and time-consuming process; however, if done diligently with a designed implementation plan and clear steps, you can maximize its success while saving time and money. What is[...]

Top 3 Benefits of Supply Chain Management

October 15, 2018

[vc_row][vc_column][vc_column_text]When looking for an ERP solution it’s important to find one that will take care of your entire supply chain management needs. The ultimate goal of efficient supply chain management is reducing the inventory costs of your organization. And, if your organization has difficulty tracking goods consumption and product[...]

Why Are Manufacturers Switching to Cloud ERP?

October 12, 2018

Is Cloud ERP a bunch of hype? Can it help to evolve and strengthen core business functionalities? Cloud-based ERP is hosted on a cloud computing platform and managed by the vendor. Backup and disaster recovery plans are available to ensure work is not interrupted. For small and mid-sized businesses,[...]

Emerging Global Trends in Advanced Manufacturing

October 10, 2018

Technology is the enabler of industrial advancements! According to IDC predictions, by the year 2020, 60% of manufacturers will depend on digital platforms which may help them increase their overall bottom-line by 30%. Doesn’t it sound amazing? Gone are those days when manufacturing was labor-intensive. Over the past few years,[...]

Role of Cloud ERP in Digital Transformation

October 8, 2018

Digital transformation is the driving force of modern businesses. It encourages paperless transactions, informed decisions, and real-time information. Technologies such as Blockchain, Internet of Things, Artificial Intelligence, Machine Learning, Cloud, etc. are all contributing to the digital transformation process. These are the services that enable Industry 4.0 and encourage[...]

7 Key Integrations for Manufacturing ERP Software

October 4, 2018

ERP, Enterprise Resource Planning software encompasses a set of tools that collects, organizes, and updates the business data in one system. Manufacturing ERP software offers functional choices to buyers, which can be overwhelming. Enterprise Resource Planning software has become a bedrock in the manufacturing industry. It not only streamlines[...]

5 Must-have Features of a Warehouse Management System

September 27, 2018

A warehouse is the cornerstone of every manufacturing organization. It is simply a central location where goods are procured, stored, and distributed for further processing. From handling major and minor warehouse operations such as inspection, procurement, acceptance, put-away, picking, packing, order assembly, and shipping, a warehouse management system (WMS)[...]

5 Common ERP Implementation Mistakes Every SME Should Avoid

September 25, 2018

Tougher competition in the market encourages businesses to better optimize resources, ensure customer satisfaction, and improve productivity. An Enterprise Resource Planning solution helps manufacturing organizations optimize business operations to increase growth. Selecting an ERP is a complicated and time-consuming task that requires exhaustive research and evaluation of multiple options.[...]

How Long Does It Take to Implement a Fully Functional ERP System?

August 3, 2018

Gone are the days when ERP was merely a business management software in which only big budgeted companies invested. Now, it has become an indispensable and integral part of the business that streamlines daily processes and boosts the bottom line. ERP implementation is a major task that requires organizations[...]

5 Benefits of Automation in the Manufacturing Industry

July 30, 2018

There has been a big shift from the way manufacturers worked in the past thanks to modern technologies that streamline operations. Long ago, factories hired a large number of workers to carry out each activity - this consumed more time and it could be a bit chaotic. Today, manufacturing[...]

Benchmark the Best-In-Class Solution for your IM&C Business

July 24, 2018

Industrial Machinery and Components is a huge industry that depends on complex products and manufacturing processes to produce goods. Considering the growing global competition, every manufacturer aims to balance customers’ demand for improved responsiveness and growth. An Industrial Machinery and Components business requires advanced technology that can drive the[...]

What is Agile Manufacturing and How Can it Help you Succeed?

July 19, 2018

Digitization allows companies to accelerate the pace of innovation and turn speed and agility into a competitive advantage. This is the age where factories are connected smartly with high-tech solutions to better plan and manage resources and processes. Nowadays, manufacturers are embracing lean and agile manufacturing initiatives to improve[...]

7 Stock Control Methodologies Manufacturers Should Practice

June 15, 2018

“The most dangerous kind of waste is the waste we do not recognize.” – Shigeo Shingo, leading expert (Toyota Production System) In this dynamic manufacturing world, customers’ demand is unpredictable and inconsistent. Manufacturers struggle a lot while managing their stock, inventory operations, and transactions. When we talk about stock[...]

How Can IoT Technology and ERP can Benefit Manufacturers?

June 11, 2018

Gone are the days when sales personnel would maintain piles of paper sheets in their office or spreadsheets on their computers to process information. Today businesses, whether small or large, invest in state-of-the-art software that can make their work easy and eliminate issues. Managing a business is not easy.[...]

What is GDPR and What is its Significance in the Manufacturing Industry?

May 25, 2018

GDPR has become a buzzword in recent times. Everyone is talking about this profound EU regulation that’s going to create a huge impact in the European countries. EU General Data Protection Regulation (GDPR) is a directive that will replace the current 1998 Data Protection Act from May 25, 2018,[...]

How Can an ERP System Improve Inventory Accuracy?

May 11, 2018

“Make your product easier to buy than your competition, or you will find your customers buying from them, not you.” – Mark Cuban In today’s dynamic world, managing every aspect of your business is imperative to productivity. Unquestionably, inventory is one of the largest expenses incurred by businesses as[...]

Five Benefits of ERP in Automobile Components Manufacturing

May 10, 2018

The automotive industry is one of the largest and most versatile sectors around the globe and is evolving continually with imminent resurgence. With a record-setting pace, the automotive industry has forecasted increased global sales of passenger cars to hit the market. Considering the rising global competition, it is always[...]

How close a match to my industry requirements can an ERP system get?

May 9, 2018

I was once showing a prospect an ERP solution, and the business owner asked “What does this ERP system specialize in?” “Wholesale / Distribution”, I replied. “Woop-de-do,” was the response, “so do 90% of all ERP systems”. That was back in the days when ERP Systems tried to be[...]

Time to Take a Leap – Grow from MRP to ERP!

May 3, 2018

MRP, also known as Material Requirement Planning, is a business planning tool used by organizations to manage production planning, inventory control, and scheduling. It ensures timely availability of material, optimum utilization of resources, planning for manufacturing, and procurement functions. To be precise, an MRP system emphasizes three major functions,[...]

How customizable does my ERP need to be?

May 2, 2018

One of the first questions asked by a prospective customer when evaluating a possible ERP solution is: Can I customize this software? Whether the need to customize is real or not, it is often an important consideration in terms of “future-proofing” the chosen ERP solution. Proprietary ERP is often[...]

How Can Material Requirement Planning Create a Difference in Manufacturing?

April 26, 2018

In this modern world, every manufacturer is looking for ways to reduce costs and optimize business operations to the fullest. When we talk about the manufacturing industry, production and resource optimization are crucial to an organization’s profit. MRP or Material Requirement Planning software was developed in the 1960s to[...]

How free is “Free”?

Open Source software is free, right? We can save a fortune using it, can’t we? Well, that depends….. The attraction of Open Source software is not just that the initial license is free, but you also avoid on-going annual maintenance fees of around 20-25%. That’s a powerful incentive, but[...]

Different Types of ERP Systems: What’s the Most Suitable for Manufacturing?

April 25, 2018

For every business owner, selecting an ERP solution is quite an expensive and labor-intensive affair. ERP is software that seamlessly integrates organizational data into a single system. From inventory management to human resources, quality control to production and supply chain, it addresses all aspects of a business. When we talk[...]

Have you considered the advantages of cloud ERP?

April 19, 2018

To compete and grow, your company needs an ERP solution that is flexible and agile. Over the past 20 years Cloud ERP solutions have repeatedly proven their superiority in up-time, data security, and agility when compared to on-premise ERP systems. As a result, on-premise applications are quickly becoming a[...]

Is ‘Best of Breed’ really ‘Best’ for you?

April 12, 2018

A ‘Best of Breed’ solution is designed to do extremely well for one department or area of your business. Each such solution is usually developed and supported by individual, separate vendors. An ‘End-to-End’ ERP system, sometimes called ‘Best-in-Class’, combines all the different departments and areas of your manufacturing business[...]

Want to Keep Pace with Technology? An Annual Maintenance Contract is the Key

April 10, 2018

Without any doubt, Enterprise Resource Planning software is the backbone of the manufacturing and distribution industry. It brings every information, operation, and task on the same platform and ensures that resources are utilized in the best possible manner. Your ERP solution is critical to the success of your business. It’s[...]

Accelerate Innovation in the High-tech Manufacturing Industry with ERP

April 6, 2018

It’s no secret that technology is driving every facet of the world. This is the era where demanding markets require cutting-edge technology that can support IoT capabilities and business intelligence functions. Today, high-tech market leaders are aiming to create a smart manufacturing environment that has all the capabilities to[...]

Unpacking the Benefits of ERP in the Wholesale and Distribution Industry

April 4, 2018

Wholesalers and distributors serve a crucial role in the product distribution channel. As technology has evolved, distribution businesses have witnessed ample opportunities and complexities. Nowadays, consumers have become more tech-savvy. They have mobile devices that allow them to easily order a huge range of products including groceries, home décor,[...]

How to Manage Business Complexities in the Medical Device Manufacturing Industry

March 26, 2018

The medical device manufacturing industry is one of the most crucial and life-saving industries in the world is largely affected by economic downturns, population demographics, and technological advancements. It deals with a huge range of components such as hypodermic needles, syringes, implanted defibrillators, female diagnostics, and cardiac monitoring equipment.[...]

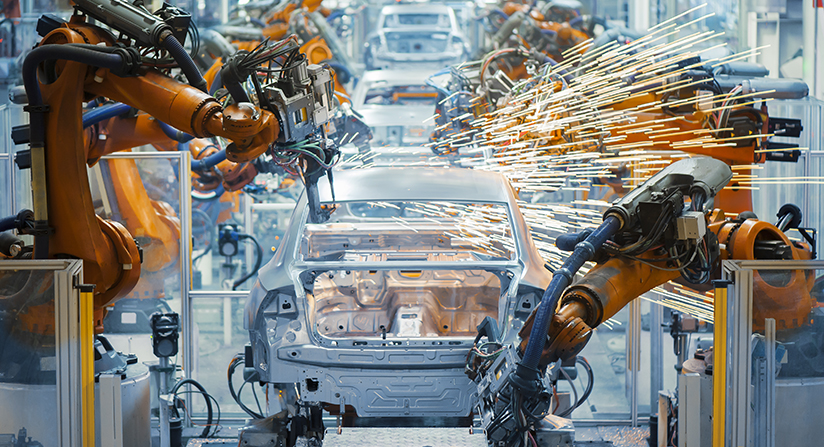

Why Automotive Manufacturers Are Using ERP and Why You Should Too

March 22, 2018

The auto industry is on the verge of a revolution. It plays a massive role in the global economy. As a dynamic and customer-driven industry, the automotive sector deals with components of different sizes and varieties that are required in varied workstations for assembling, polishing, and painting automobiles and[...]

Addressing the Business Needs of the Telecommunication Industry with ERP

February 7, 2018

Technology is driving the business world and businesses of all sizes are striving hard to embrace it. The telecommunications industry contributes significantly to the world economy. Enterprises in this sector manufacture and design a wide range of products – multi-million dollar room-sized switches to basic mobile phones. To satisfy[...]

4 Ways to Strategize Manufacturing Quality and Reduce Recalls

January 25, 2018

In this age of Industry 4.0, manufacturers seek an automated Quality Management System (QMS) that eliminates the need for hunting for a document in multiple locations. Businesses look for a solution that allows them to collect and aggregate data in real-time and keep each piece of information in a[...]

How Can a Warehouse Management System Drive Your Business Productivity?

January 15, 2018

Is your business still using spreadsheets to manage warehouse transactions and records? Or do you rely on manual processes for maintaining inventory and its data? Well, these are old and archaic methods of handling day-to-day warehouse operations. And, in either case, you need a solution that lets you keep[...]

How to Solve Biggest Problems in a Small Manufacturing Business

Every manufacturing business be it small, medium, or large faces some common operational concerns. But there remain some challenges that are unique to businesses of a certain size. A small manufacturer may come across operational issues that a large manufacturer doesn’t. This blog focuses on one such set of[...]

ERP Software Advantages Every Manufacturer Must Know

January 12, 2018

Every business is unique, so are the challenges. But quality adherence, delivering goods on time, and cash flow and costing, are some of the issues which keep manufacturers on their toes. You work endlessly to optimize resources but as the business scales so do its requirements. And you look[...]

5 Factors to Consider Before You Decide on a Discrete Manufacturing ERP Solution

The decision to implement an ERP solution is often difficult. But choosing an ERP vendor is even more challenging. As a result, you search online, scan vendor websites, and speak to salespeople, but still have difficulty deciding. Just because a vendor has a strong online presence doesn’t mean they[...]

6 Ways to Reduce Inventory Levels

August 16, 2017

For any small to medium-sized manufacturer, the ability to effectively manage inventory can determine a company’s success or failure. Lean manufacturing principles identify inventory as one of the most critical “wastes” to be eliminated. If inventory is not constantly moving through the production process then it is a “non-value add” and[...]

Improving Quality Assurance in Lean Manufacturing

August 9, 2017

[vc_row][vc_column][vc_column_text] Quality management is embedded within core lean manufacturing principles, however improving quality assurance even further for small and large manufacturers alike, can be achieved by adopting Six Sigma techniques and strategies. Lean manufacturing is a philosophy of continuous improvement (kaizen) with the goal of providing extraordinary value to the[...]

10 Steps to Selecting an ERP System for Your Manufacturing Business

August 1, 2017

An ERP system is arguably the core infrastructure of any manufacturing operation. It connects every function within the organization providing all of the required data to drive the business efficiently, productively, and profitably. It can handle customer orders, customer relationship management, purchasing, production planning, inventory management, accounting functions, HR functions, and[...]

6 Warning Signs Your Manufacturing Business Needs An ERP System

July 25, 2017

Your salespeople are doing a great job drumming up business. But you are having a problem keeping up with demand and you can’t figure out why. Production holdups are increasing, quality standards are dropping, delivery schedules are not being met and your customers are becoming increasingly unhappy. Sound familiar?[...]

Lean Manufacturing Best Practices – How to Get Started

July 19, 2017

When you start researching lean manufacturing for the first time you’ll be confronted with myriad principles, concepts, processes, and tools, each of which has to have their own acronyms of course. Lean manufacturing best practices are not that complicated! They are based on 3 common-sense principles: A laser focus[...]

Will Lean Principles Help My Small Manufacturing Business?

July 11, 2017

The short answer is a resounding yes! You can be a 2-person job shop or a 5000-person aircraft manufacturer and lean manufacturing principles apply equally. Lean manufacturing is a philosophy of continuous improvement (kaizen) with the goal of providing extraordinary value to the customer through a process of eliminating[...]

4 Lean Inventory Management Best Practices

July 5, 2017

The primary goal of lean manufacturing is to eliminate waste, (anything that doesn’t add value from a customer perspective), and inventory falls within that scope. So essentially lean inventory management best practices are focused on reducing inventory levels to zero. A worthy goal, but impractical to say the least. However, lean[...]

Which Inventory Control Method Is Right For You?

June 26, 2017

Efficient inventory control is critical to the profitability of any manufacturing enterprise. However, with so many methods of inventory control available, it can be overwhelming to sift through them all to determine the best fit for your company. In general, manufacturers want to find a system that optimizes inventory[...]

The Unparalleled Benefits of ERP Integrated with Business Intelligence

June 19, 2017

What is ERP? Enterprise Resource Planning (ERP) is a comprehensive and integrated software solution designed to streamline and optimize various organizational business processes. ERP systems efficiently manage core functions such as finance, human resources, supply chain, manufacturing, and customer relationship management by providing a centralized data storage and processing[...]

Are You Smart Manufacturing?

June 12, 2017

A few months ago, we published a blog entitled “The Future of Manufacturing – Are You Prepared?” in which we stated that “… today’s manufacturing companies must reconfigure to emphasize agility, flexibility and ‘smartness’ in order to remain competitive in a rapidly evolving marketplace.” Indeed, the rapid-fire emergence of[...]

How Mobility Increases ROI

June 6, 2017

In a previous article, we shared some insights into the rapid ascendance of mobile devices as key components in today’s ERP solutions and some of the high-level benefits that manufacturers can reap from their use. Entitled “The Top 5 Reasons Your Business Needs a Mobile Solution,” we supported the[...]

Quality Assurance & Quality Control Why You Need Both

May 15, 2017

In last week’s blog, we looked at quality assurance (QA) best practices for manufacturers. In that post, we touched on the fact that many use the terms quality assurance and quality control (QC) interchangeably, even though they represent different functions in the overall quality management process. As we noted[...]

5 Quality Assurance Best Practices for Manufacturers

May 8, 2017

In a manufacturing organization, quality management is an important process that ensures error-free and timely delivery of products to customers. When your products are not delivered on time or have defects, it hurts your business reputation. In this blog, you will learn what quality management is and the benefits[...]

Inventory Management 101 – The Master Production Schedule (MPS) Explained

May 3, 2017

Master production scheduling is the process that helps manufacturers plan which products and related quantities to produce during certain periods. It is proactive, driving the production process by determining what should be manufactured and what materials should be purchased. In previous articles, we introduced Bills of Materials (BOM) and Material Requirements Planning (MRP),[...]

The 10 Types of Bill of Materials (BOMs) Explained

April 17, 2017

In our last post, we focused on the advantages of automated BOMs vs. manual spreadsheet-based systems. Today, we’re going to drill down a little further into types of BOMs (Bill of Materials) so you have a better understanding of some of the available options. What is Bill of Material[...]

How Automated BOMs Can Save You Time, Money and Eliminate Mistakes

April 10, 2017

A bill of materials (BOM) is a list of the raw materials, assemblies, sub-assemblies, components, sub-components, and associated quantities plus labor and equipment needed to complete a job. The BOM also requires quality control over each step in the process to ensure that no defective or substandard components find[...]

What Is Cycle Counting & Why Is It So Important?

April 3, 2017

Cycle counting is an efficient and cost-effective way to ensure the ongoing accuracy of your inventory counts and valuation. Usually, staff will perform cycle counts on a predetermined schedule, often weekly or monthly, and count a subset of the entire inventory in a specific area of the warehouse. Once[...]

5 Critical Inventory Management Best Practices

March 28, 2017

Any small- to mid-size manufacturing business knows that effective inventory management is critical to success. With inventory tying up working capital stock turn is paramount. In addition non-turning stock takes up valuable space, may become outdated or obsolete and there is always a danger of shrinkage. It is critical[...]

7 Reasons Why Cloud ROI Might Be Too Good to Resist

March 21, 2017

The cloud has permeated nearly every sector of business and manufacturing is certainly no exception. The reasons are many for this transformation but one in particular is that Cloud ROI might just be too good to resist. In the pre-cloud days, we lived in a time of expensive and[...]

Reduce Costs & Delivery Times With Procurement Automation

March 14, 2017

Procurement automation can reduce the cost of purchase order requisition, submittal and approval by up to 75% and invoice processing costs by up to 90%. According to the American Productivity & Quality Center (APQC) companies using procurement automation receive deliveries two days faster on average than those who don’t.[...]

EDI is Critical to Successful Supply Chain Management

March 6, 2017

EDI (Electronic Data Interchange) enables the electronic transfer of business information between trading partners (B2B) through a standardized format. EDI technology has been around for roughly 50 years, originally developed by the U.S. transportation industry to standardize electronic transactions between vendors and customers. This highly efficient process is entirely[...]

7 Ways to Win New Customers

February 27, 2017

If you’re part of an emerging small business, keeping track of your customers’ histories, sales opportunities, marketing campaigns and other key data points is likely essential to your future success. The question is … Are you still depending on inefficient and error-prone spreadsheets and disconnected databases for this information[...]

The Future of Manufacturing – Are You Prepared?

February 21, 2017

When it comes to the world of discrete manufacturing, old paradigms are slow to change. The long-held stereotypes still persist of outdated, decrepit workplaces that operate at sub-standard efficiency levels and often without adequate safeguards to protect worker safety. Until recently, the “old school” manufacturing model was dominated by[...]

The Top 5 Reasons Your Business Needs a Mobile Solution

February 13, 2017

There are countless reasons why manufacturing businesses are increasingly relying on mobile apps to maintain 24/7 access to real-time data that helps them perform better. Yes, the quaint days of lugging around loads of paper and/or having to call the office to keep track of sales, review customer history[...]

6 Hidden Costs of Stockouts

February 6, 2017

[vc_row][vc_column][vc_column_text]Generally speaking, when a manufacturing/distribution enterprise experiences a stockout, the ramifications can be troubling on many fronts. A host of factors may be responsible for an inventory shortfall, such as unforeseen demand, poor inventory management or delays in getting product to market. Regardless of the reason, a stockout is[...]

5 Key Advantages of SAP Business One vs. QuickBooks

January 31, 2017

[vc_row][vc_column][vc_column_text]OK, let’s say you’re either ready to upgrade from QuickBooks to a more robust ERP solution or you’re at least open to considering options. If you’ve already commenced your search, you likely discovered a large number of ERP choices on the market today that claim to be “affordable”. The[...]

6 Telltale Signs Your Business Has Outgrown QuickBooks

January 23, 2017

[vc_row][vc_column][vc_column_text]QuickBooks is omnipresent. Over five million users and counting. It’s the industry-standard choice for start-up businesses to meet their basic accounting requirements at a very user-friendly price point. In fact, there’s a good chance QuickBooks was your first purchase when you started your business. Or perhaps you’re still using[...]

Why Manufacturers Require 5 Degrees Of Connectedness

July 31, 2016

[vc_row][vc_column][vc_column_text]Analysts tell us the Internet of Things (IoT) will result in 34 billion connected devices by 2020, up from 10 billion today. That level of connectivity promises to transform a lot of business processes and business models. But IoT is only one type of connectivity. Today’s manufacturers must connect multiple[...]

5 Reasons Manufacturing SMEs Need Cloud More Than Ever

[vc_row][vc_column][vc_column_text]The business environment for sales teams in manufacturing and engineering industries is increasingly demanding: IT infrastructures have become complex, at the same time that everyday sales activities claim simplicity and ease. Additionally, CEOs demand a clear overview of incoming opportunities and the business process. So how do cloud solutions help[...]

Simplify Complex Manufacturing For Greater Efficiencies

July 30, 2016

The manufacturing of large things – like aircraft, ships, or other complex, integrated assemblies – can take months or years to build. These products are typically produced in low volumes using high-touch labor, and because of their complexity, the manufacturing process may involve parts that are subject to continuous[...]

5 Digital Trends in Wholesale Distribution

June 23, 2016

We are witnessing an unmatched era of market change and true business innovation. Industry lines are becoming blurred, offering new opportunities–but also creating new competition. Distribution companies need to innovate and adapt, or they will lose market share. Breakthrough technologies have been driving and enabling some of these trends.[...]

Mobile Is A Critical Driver For Business Success

Mobile is the crux of innovation in business today—it isn’t just something to think about, it’s critical to business success. A new survey from SOTI, a provider of Enterprise Mobility Management (EMM) solutions, shows most organizations get it: 2016 will see major investments made in mobile technology and EMM[...]

4 Vital Steps for Survival in the Digital Economy

Are you prepared for digital upheaval in your sector? Or could you fall victim to Digital Darwinism, when technology advances faster than your organization can adapt? Businesses that don’t adjust to the growing networked economy risk becoming irrelevant in their industry. According to the SAP eBook, The Digital Economy:[...]

Next Generation ERP for Manufacturing and Distribution

May 5, 2016

OptiProERP was designed to supplement the basic functionality of SAP Business One (“traditional” ERP, deep in finance, less so in operations) to build a Next Generation total ERP solution specific to Manufacturing and Distribution companies. These companies’ needs include Routing, Quality Control and Subcontractor Management (a specialized portion of[...]