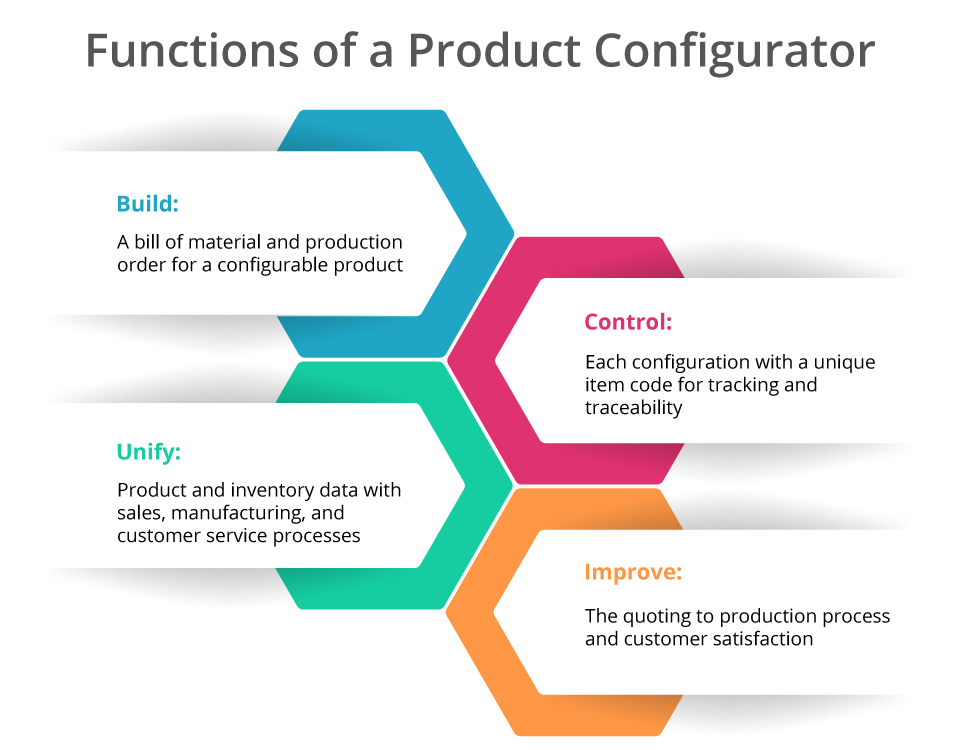

For manufacturers that offer their customers configurable products or made-to-order products, a product configurator helps speed and streamline order processing. It also creates automated BOMs to ensure the product is manufactured according to customer specifications. In this blog, we will dive into what a product configurator is and how it can speed up order processing.

What is a Product Configurator?

A product configurator allows users to customize products by selecting features, colors, materials, sizes, and finishes. For example, an electric car manufacturer could use a product configurator on its website to allow customers to customize their vehicles according to their preferences and needs. With a product configurator, customers could choose from various options such as color, interior features, battery size, and additional packages like self-driving capabilities or performance upgrades. This tool not only enhances the customer’s purchasing experience by giving them control over the final product but also streamlines the manufacturing process by providing precise specifications for each customized vehicle, reducing waste and improving efficiency on the production line.

A Product Configurator Can Help You If:

- Your engineers spend too much time creating estimates rather than designing products.

- Your sales team has limited time to prospect and talk to customers because they’re buried in paperwork from manually creating quotes.

- You want to reduce errors with pre-defined rules that create valid configurations and accurate pricing.

- You want your customers to be able to build their specific product and see the pricing, stock availability, and lead time needed to deliver that product.

- You want your production, purchasing, and inventory staff be able to better plan and schedule to meet customer demand/orders.

- You want greater market share by increasing throughput and making it easier for dealers and distributors to sell your products.

The Benefits of A Product Configurator:

- It allows you to make multiple revisions of the same configuration while maintaining a history of the revisions and who created them.

- It uses various features, dimensions, and functions to minimize the number of BOMs needed to complete a finished product.

- It uses multiple pricing capabilities, pricing options, and features to determine the actual unit price of a configured item.

- It lets you quickly create BOMs, quotes, sales orders, and production orders with easy-to-use rule-based functionality.

How Does a Product Configurator Empower Marketing and Sales?

A product configurator allows the sales team to assemble sales orders or quotations when they are out of the office. It gives them an accurate price list to speed up the configure-to-quote process.

The sales and marketing team can respond to customer orders more efficiently. It provides the marketing team access to all the critical business data needed to enhance the company’s overall business strategy. Product information, popular product options, and product profitability are used for target marketing and sales accordingly.

How Does A Product Configurator Increase Revenue For Manufacturers?

1. Quick and accurate design

With a product configurator, customers’ requests can be easily modeled before production. They can provide specific features and parameters, and the software can configure the design quickly. This helps you eliminate the timely process of interpreting the customer’s request and creating the product specification.

2. Reduces the risk of errors

A product configurator helps produce made-to-order products by consolidating detailed information from your customers. It allows you to convert a sales order to a production order for a configured or made-to-order product. It also helps the sales and manufacturing departments cascade information, leading to fewer errors.

3. Optimizes production

When the BOM and product manufacturing steps are complex and custom-made, the production department may face difficulty organizing the production process. A product configurator is used to plan and execute the most efficient methods and schedules for the production process. It cuts organizational complications and manual errors.

4. Reduces production time

A product configurator minimizes the time between placing an order and shipping it to the customer. Without a product configurator, customers have to wait until the configuration is determined and prices are finalized and quoted. But with a product configurator, sales reps can show customers many configuration options in a matter of seconds and recommend the best options available.

5. Helps customers configure unique products

Every manufacturer wants to improve customer satisfaction. And customers love to have multiple options to make a custom product and the control to do so. The ability to configure and plot a different aspect of the order means customers can build their specific product more seamlessly. This leads to higher customer satisfaction and more customer orders.

6. Improves marketing and customer service

A Product Configurator can provide customers with an accurate lead time based on stock availability and the ongoing production schedule. The configurator provides better clarity between customers and the sales department.

A product configurator also helps the marketing team identify trends in requests and materials that sell well by using data history. This information helps to improve targeted marketing.

7. Provides quotes and BOMs with ease

When the customer develops unique and complex products for manufacturing, the product configurator makes it easier to create an accurate quote and comprehensive BOM. It simplifies understanding what materials are required for production and how much they will cost.

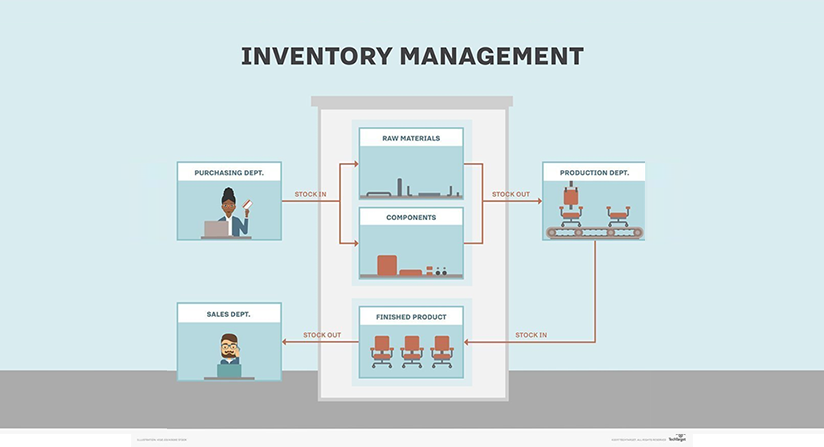

How Do Automated BOMs Improve Productivity?

An automated BOM uses state-of-the-art algorithms to scan through product designs and identify critical components needed in the production cycle. A BOM lists all required parts, part numbers, pricing information, and quantity.

An automated BOM system in the production process helps manufacturers:

- Maintain optimal stock levels of materials

- Utilize real-time data to help with planning of production schedules and costs

- Integrate data from all departments, including production, accounting, sales, warehousing, and more

- Combine all components, such as part number lists, spreadsheets, engineering drawings and all other documents into one system

How OptiProERP Helped EPC Power Corp Configure Products and Achieve Increased Productivity

OptiProERP with SAP Business One is a complete business management solution for manufacturers and distributors that connects all business processes in one cohesive system. It eliminates the need for multiple tools to manage different aspects of a business.

EPC Power Corporation, North America’s largest energy storage inverter manufacturer, chose OptiProERP to replace its legacy ERP, Odoo, because it did not have a product configurator or the manufacturing capabilities they needed. They evaluated many ERP systems including, Epicor, IQMS, Acumatica, and Global Shop Solutions, before choosing OptiProERP with SAP Business One. Below are the challenges EPC Power was facing:

- Their legacy ERP lacked manufacturing capabilities for customers to adopt sustainable and green power options.

- Their legacy ERP was slow and did not have front-end configurators, BOM control, and after-sales service.

- Their scope of customization was too limited.

The below quotes are from Eli Aharon Ezer, the ERP Project Manager for EPC Power Corporation, explaining why they decided to look for an ERP and why they eventually chose OptiProERP with SAP Business One.

“We’ve grown a ton, but trying to do something in Odoo takes tons of time. Odoo is slow, lacks front-end configurators, accounting traceability, after-sales service, and its BOM controls are lacking.” “At the end of the day, OptiProERP with SAP Business One had all the manufacturing functionality we wanted. We also look forward to restructuring our BOM and having a configurator to say we want the product to be this color or stainless steel. The BOM would be automated and generate work orders. We want everything to be streamlined without needing manual, intermittent steps.”

– Eli Aharon Ezer, ERP Project Manager, EPC Power Corp.

Conclusion

Manufacturing ERP software allows manufacturers to manage all business departments on one software platform, from receiving customers’ orders to fulfilling them and handling post-sales services. A product configurator is one of the manufacturing ERP modules that helps manufacturers create quotes, build automated BOMs, and process a production order for configurable products with unique part numbers and component compositions.

Follow Us