In the words of Henry Ford: “If you always do what you always did, you’ll always get what you always got.”

The manufacturing sector is becoming increasingly efficient, modular, automated, and customized. Manufacturers that embrace new technology are much more likely to reach their full potential. But manufacturers are slow adopters of evolving technologies and many of them resist making changes and therefore miss new opportunities.

If you are reading this blog, you may be considering investing in modern technology-driven software to improve business growth. Often manufacturers find themselves in one of the following categories. See if any of them relate to your business.

- They are operating on a legacy system(s)

- Their business software doesn’t meet industry-specific needs or support evolving technologies

- Their hardware is outdated and cumbersome

- All of the above

Outdated technology can hurt your business by creating greater risk, lowering productivity, and slowing growth. To optimize business operations, it’s important to incorporate technology that provides the benefits you need to successfully run your enterprise.

What are the hidden costs of using outdated technology?

1. Data security

Running outdated operating systems and servers can create security risks. It also can aggravate existing compliance challenges of which you may not even be aware. Even small and midsize businesses should not assume they are too small or not important enough for hackers to target.

2. Migration/installation and higher cost

As legacy software becomes older, it will fail more often and require greater maintenance which ultimately leads to higher costs. Manufacturers may feel migrating to modern software requires huge expense. But, an experienced migration partner and an emphasis on the right application(s) helps to minimize the cost of a modern software system(s). Benefits gained from software that works with your company instead of against it, is essential to achieving greater productivity and success.

“By 2025, Gartner estimates that over 95% of new digital workloads will be deployed on cloud-native platforms, up from 30% in 2021.”

3. Data loss

Backing up business data is a crucial part of every business. If your backup solution is out-of-date, there are higher chances of losing data. Loss of customer, sales, or finance data can directly affect a business’s bottom line.

4. Lower employee productivity

Outdated technology can restrict your employees from achieving higher productivity. It may even cause them to look for jobs where they can work with modern systems. Decreased efficiency and productivity hurts your business revenue. Modern software comes with improved functionality to help employees perform at peak levels and it can help with employee retention.

Is old technology preventing your business from achieving more?

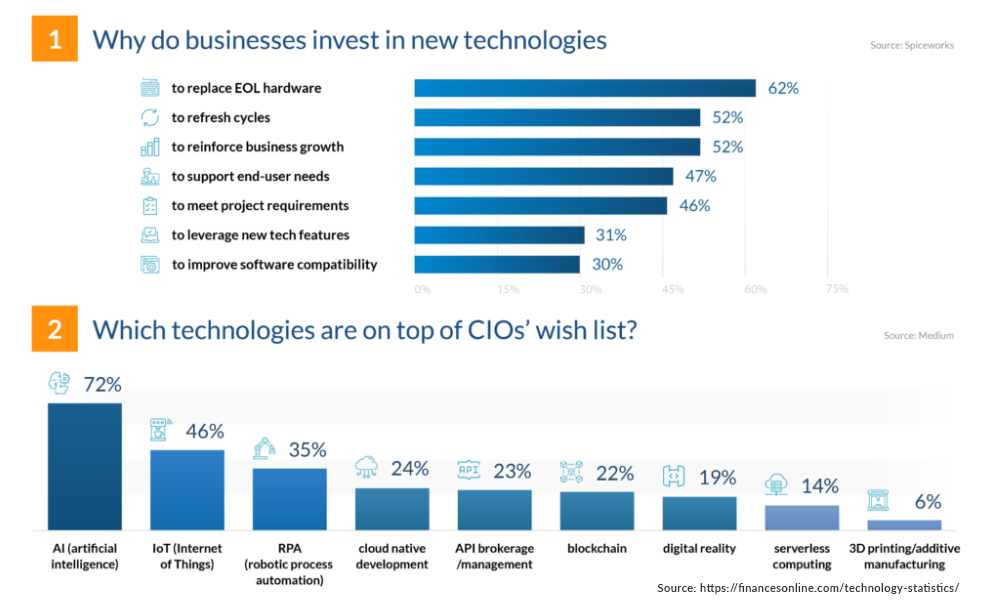

Technology is an investment that can help businesses increase productivity and improve their competitive advantage. Overlooking necessary changes and updates in technology can lead to inefficient processes and obsolete machines. Outdated technology can make a business less competitive by not providing employees with the tools they need to do their jobs effectively.

Businesses using spreadsheets and paper-based documents can’t compete with companies that have newer hardware, innovative and automated software, and real-time visibility. The ease of use, reduced costs, and increased efficiency of new technology provide businesses with a greater advantage.

“A new survey finds that responses to COVID-19 have accelerated the adoption of digital technologies by several years. And that many of these changes could be here for the long haul.”

Let’s see why some companies are reluctant to switch from legacy software to modern systems.

-

They haven’t considered that their competition is on the cloud

-

If the current system isn’t broken, don’t fix it

-

Reluctant to change

-

Implementation timeline

Gartner says that Cloud will be the centerpiece of new digital experiences (global cloud revenue to total $474 billion in 2022, up from $408 billion in 2021).

However, many manufacturers still have not realized the importance of cloud ERP and are losing customers to competitors operating on cloud software. Cloud ERP provides data security, improved business performance, flexibility, and easy implementation.

Read more about cloud ERP in detail here.

Another reason businesses don’t switch to modern technology is they are in their comfort zone. Businesses and their employees get accustomed to managing their tasks on legacy software.

Since the organization has made a significant investment(s) in a legacy system(s), it is hard for them to move to modern software. It’s also likely they don’t want to go through an implementation or undergo training to learn new processes.

Leaders are wary of the implementation process and understand it may take time to migrate to a new system. A great benefit of cloud platforms is they can be implemented quickly for a fast return on investment.

Developing an IT roadmap can help you plan for your monthly, annual, and coming years’ technology costs. Investing in a modern ERP system for manufacturing allows businesses to increase employee efficiency, productivity, customer satisfaction, and their bottom line.

Benefits of investing in modern manufacturing technologies

Implementing new business technologies can drastically transform the way your manufacturing organization operates. Here are some of the many ways it can benefit your business.

- Improve your relationships with vendors and customers

- Provide greater speed, efficiency, and flexibility in the production process

- Allow employees to focus on profit-making tasks instead of mundane ones

- Expand the range of what and how much you can manufacture

- Let you utilize Industry 4.0 technologies for greater insights and efficiencies

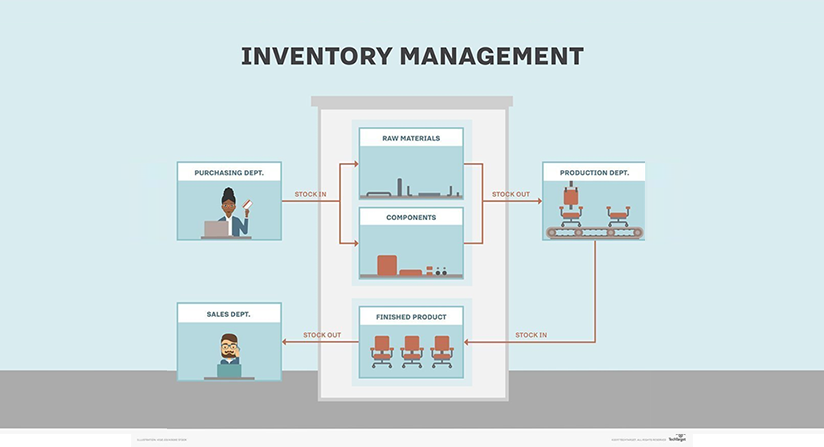

- Integrate purchasing, production, finance, sales, and other departments for streamlined workflows

- Manage, track, and evaluate tasks online, from any device

- Improve connectivity among departments for greater collaboration

What is Industry 4.0 and how is it affecting manufacturing?

Industry 4.0 refers to the latest changes in industrial development. It conceptualizes rapid changes to technology due to increasing interconnectivity and smart automation. The primary technologies of Industry 4.0 are Big Data, Digital Twins, Internet of Things (IoT), CloudComputing, Blockchain, and Artificial Intelligence (AI).

Looking ahead

Embracing new technologies in manufacturing is essential to maximizing business value, customer satisfaction, and employee efficiency. The global Industry 4.0 market is expected to grow to $165.5 billion by 2026. So, manufacturers who have not yet given thought to shifting toward modern technologies should begin to understand their benefits.

Follow Us