Generally speaking, when a manufacturing/distribution enterprise experiences a stockout, the ramifications can be troubling on many fronts. A host of factors may be responsible for an inventory shortfall, such as unforeseen demand, poor inventory management or delays in getting product to market. Regardless of the reason, a stockout is likely going to be a loser for business in the short term and if that condition persists, the fallout could be exponentially worse in the future.

Yes, due to so many variables that affect inventory management, it’s a good bet that a business will experience a stockout on occasion. While many steps can be taken internally to minimize risk of stockouts, sometimes scenarios arise that are out of one’s control, such as unexpected issues in the supply chain.

The hidden costs of stockouts often lurk below the surface. In addition to possibly losing a sale, there are a host of other related costs that may arise. Here are 6 to consider:

1: Unhappy/Lost Customers

Simply put, with order fulfillment a nearly instantaneous proposition these days, if the goods are not available, your customers aren’t going to be happy and they may take their business elsewhere. Think about it – how many times have you jumped to another supplier when your order couldn’t be fulfilled? A lost customer isn’t just a lost sale; it could be the loss of countless repeat sales. And in today’s marketplace, the possibility of a bad online review can turn off other potential customers as well. And here’s the kicker – in many cases, you may never know that they left you, so you can’t even measure the loss.

2: Lost Revenues

This is obvious but bears repeating … stockouts mean lost revenues. Add in the hidden costs that accrue when trying to remedy the condition so that a customer won’t “jump ship,” or to find a new customer to replace those lost revenues, and you can see that this a potentially expensive proposition.

3: Inefficiencies Drive up Costs

If a business enjoys high customer demand, but has poor internal planning, chronic stockouts could occur, which may lead to a myriad of hidden costs. Poor planning spawns inefficiencies and the costs to resolve those inefficiencies can be significant, especially if the inventory management system isn’t fully automated. Without automation, it is time-consuming and exasperating to locate the cause of the stockout and then resolve the issue.

In cases like this, management is often exasperated trying to find missing data while warehouse staff searches for hours to locate misplaced items. Planning is severely hampered and often ineffective due to the absence of data that would help managers optimize stock levels. A stockout may even interrupt a production schedule in order to fulfill an order.

4: Excess Inventory & Related Costs

Poor planning can lead to ordering the wrong items from suppliers, resulting in unwanted excess inventory of certain items and unrecouped costs for resolving the situation. Expediting shipping, placing additional inventory orders and additional storage needs are a few examples.

5: Backorder Costs

Sometimes, a stockout may result in a customer backordering an item, leading to additional hidden costs. For example, customer service personnel must take additional steps, such as amending the order, setting a new delivery date, adjusting (or removing) shipping charges if the backordered item was part of a larger order, etc.

6: Unwanted Freight Expenses

In some cases, a stockout might necessitate additional freight charges in order to receive expedited delivery of items needed to fulfill the order. In addition, a business may have to eat the freight charges to its customer’s location.

Of course, one can’t prepare for every variable imaginable in an effort to prevent stockouts and their hidden costs, but proper planning, supported by a fully automated manufacturing ERP system, can ensure minimal risk, which translates to lower hidden costs and higher profitability.

Balancing Cost Effective With Accuracy

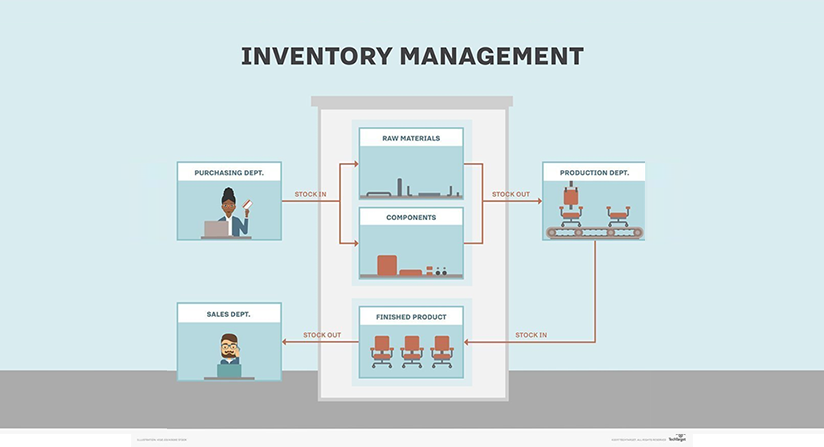

Inventory represents one of the largest expenses for many small and midsize businesses. Balancing accurate inventory management with cost-effective inventory is crucial for delivering on promise and keeping customer satisfaction high. The OptiProERP powered by SAP Business One application offers best-practice functionality to help you meet your inventory and warehouse management requirements.

Follow Us