OptiProERP’s Smart Factory is a manufacturing operations management (MOM) system that fully integrates with ERP and improves agility and productivity for manufacturers to be more competitive. In addition, it helps dramatically reduce downtime by monitoring machine performance, job changeover, and employee errors.

Smart Factory

ERP software for manufacturing and distribution

OptiProERP’s Smart Factory increases production output and reduces

cycle times, resulting in higher manufacturing efficiency and productivity

Why Choose OptiProERP’s Smart Factory Software?

OptiProERP’s Smart Factory enables manufacturers to:

- Simulate: Create optimized production schedules considering all scheduling requirements and constraints.

- Execute: Digitize processes to enable a faster time to market by responding quicker to changes.

- Acquire: Capture, view, manage, and analyze data for improved business performance and efficiency.

- Visualize: Achieve business objectives by easily monitoring production metrics through live factory KPI tracking.

Why Choose OptiProERP’s Smart Factory Software?

OptiProERP’s Smart Factory is a manufacturing operations management (MOM) system that fully integrates with ERP and improves agility and productivity for manufacturers to be more competitive. In addition, it helps dramatically reduce downtime by monitoring machine performance, job changeover, and employee errors.

OptiProERP’s Smart Factory enables manufacturers to:

- Simulate: Create optimized production schedules considering all scheduling requirements and constraints.

- Execute: Digitize processes to enable a faster time to market by responding quicker to changes.

- Acquire: Capture, view, manage, and analyze data for improved business performance and efficiency.

- Visualize: Achieve business objectives by easily monitoring production metrics through live factory KPI tracking.

Benefits of OptiProERP’s Smart Factory

Maximize Productivity

Improved Overall Equipment Efficiency (OEE) increases equipment productivity and performance.

Greater Output

Increased production output and reduced cycle time improve manufacturing efficiency and productivity.

Reduce Downtime

Improved equipment reliability and availability, reduces downtime, and increases uptime.

Improve Customer Satisfaction

Enhanced product quality and yield rates minimize waste and improve customer satisfaction.

Increase Efficiency

Optimized labor productivity leads to better workforce utilization and increases production efficiency.

Greater Asset Utilization

Improved asset utilization results in greater efficiency and effectiveness of production assets.

On-time Deliveries

Higher on-time delivery rates improve customer satisfaction and loyalty.

Lower Costs

Cost reduction through decreased material waste, reduces downtime and optimizes resource utilization.

Informed Decisions

Real-time visibility into production leads to improved decision-making and responsiveness to issues.

How OptProERP’s Smart Factory Can Work for You

OptiProERP’s Smart Factory Functionality

Asset Management

Enables companies to monitor and manage assets at various levels of granularity, from the production floor to machines and sensors.

Production

Provides real-time insights into your production process, enabling you to optimize resource utilization, reduce costs, and increase production efficiency.

IoT

Enables companies to monitor and manage assets at various levels of granularity, from the production floor to machines and sensors.

Analytics

A powerful tool that provides management with easy and dynamic data visibility, enabling control and analysis of key indicators in specific production sectors.

Operating Method Sheets

Operating Method Sheets (OMS) are electronic documents that provide step-by-step instructions for completing tasks or processes, allowing flexibility and adaptation to various scenarios.

eLearning

Offers customized training routes to cater to various personnel profiles to empower employees to learn at their own pace, anytime and from anywhere.

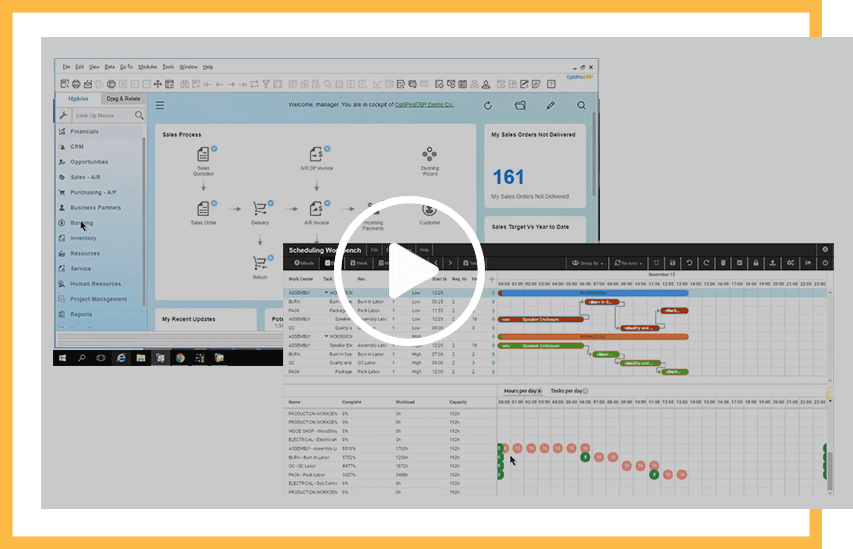

Scheduling

Includes a powerful and advanced scheduling solution to create optimized production schedules considering all scheduling requirements and constraints.

Notifications

Allows quick access to critical information in today’s fast-paced production environment through various means, including email, SMS, MS Teams, and private messaging.

Workforce Management

Streamlines the management and deployment of human capital in production processes, enabling you to optimize your workforce and improve overall efficiency.

How to Know if You Need OptiProERP’s Smart Factory

If questions like these are keeping you up, you will likely benefit

from OptiProERP’s Smart Factory.

See how OptiProERP’s Smart Factory meets your unique needs