In our last post, we focused on the advantages of automated BOMs vs. manual spreadsheet-based systems. Today, we’re going to drill down a little further into types of BOMs (Bill of Materials) so you have a better understanding of some of the available options.

What is Bill of Material (BOM) in the manufacturing sector?

BOMs are a comprehensive list of raw materials or assemblies required for production. While there are many types of BOMs, some of which are unique to specific business sectors, the following 10 types of BOMs stand out as the most common for the manufacturing and engineering industry. Let’s see what are the types of BOM you should learn about: :

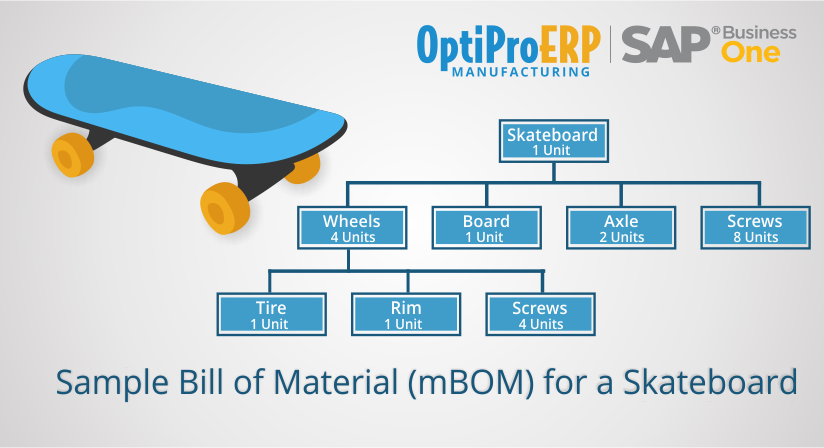

1. Manufacturing Bill of Materials (mBOM)

The manufacturing BOM (mBOM) is used when a business needs to show all of the parts and assemblies required to build a finished product. Parts that require processing before assembly must also be included in the mBOM. The document contains information that is disseminated to all of the integrated business systems involved in ordering parts and building the product, including Enterprise Resource Planning (ERP), Materials Resource Planning (MRP), and in some cases, a Manufacturing Execution System (MES). This is the most common type of BOM for a manufacturing company.

The mBOM depends on the accuracy of the quantities of parts ordered during the manufacturing process. This enables the purchasing department to maintain an optimal schedule for parts procurement while negotiating the best possible price from applicable vendors.

2. Engineering Bill of Materials (eBOM)

The engineering BOM (eBOM) is developed during the product design phase and is often based on Computer-Aided Design (CAD) or Electronic Design Automation (EDA) tools. The document usually lists the items, parts, components, subassemblies, and assemblies in the product as designed by the engineering team, often according to their relationships with the parent product (main product) as represented in its assembly drawings. And it’s not unusual for more than one eBOM to be associated with one finished product.

3. Service BOM

The service BOM (often developed by engineers during the design phase) typically includes a list of all the parts, installation steps, and repair instructions service technicians use when installing or servicing a product onsite at the customer’s place of business.

4. Sales BOM

Unlike other types of BOMs, a sales BOM provides details of a finished product before its assembly during the sales phase. In a sales BOM, both the finished product and the components appear as separate items in the sales order document. In addition, the parent item will be listed only as a sales item, not as an inventory item, and the children will be listed as sub-items of the parent item.

5. Assembly BOM

An assembly BOM is similar to a sales BOM in which the parent item is listed as a sales item and not an inventory item. However, a notable difference is that, unlike the sales BOM, only the finished product appears in the sales document; the children do not appear as sub-items. Also, assembly BOMs can be either single-level or multi-level, which we will explain below.

6. Production BOM

A production BOM often serves as the foundation for a production order. It lists the components and subassemblies that comprise a finished product, as well as prices, descriptions, quantities, and associated units of measure. During the production process, physical components can be converted into actual finished products. With a fully automated BOM system, component needs, cost, and materials available can be automatically added to work orders, thus ensuring that raw materials are properly allocated to products.

7. Template BOM

A template BOM is a highly flexible form of BOM that can be used for either production or sales BOMs, usually with the parent items displayed first and then the components below. One can update the quantity of those components, swap them out and replace them with other components or delete them in the BOM or on the sales order.

8. Configurable BOM (cBOM)

A configurable BOM contains all the components required to design and manufacture material to a customer’s specific requirements. The cBOM is often used in industries that have highly configurable products such as job shops, heavy machinery, and industrial machinery.

9. Single-level BOM

A single-level BOM is typically used for products whose constructions are not complex and do not include sub assemblies. Typically, this document contains a total count of all the parts used in the construction of a product and those parts are listed in part number order. The structure of this type of document only allows for one level of children in components, assemblies, and materials.

10. Multi-level BOM

In contrast to a single-level BOM, a multi-level BOM tends to be used for more complex constructions and therefore includes sub assemblies, often broken down into further levels of sub assemblies. In this document, each item number (either raw material or labor) must associate with a parent item, except at the top-most level.

Why Use a Bill of Materials?

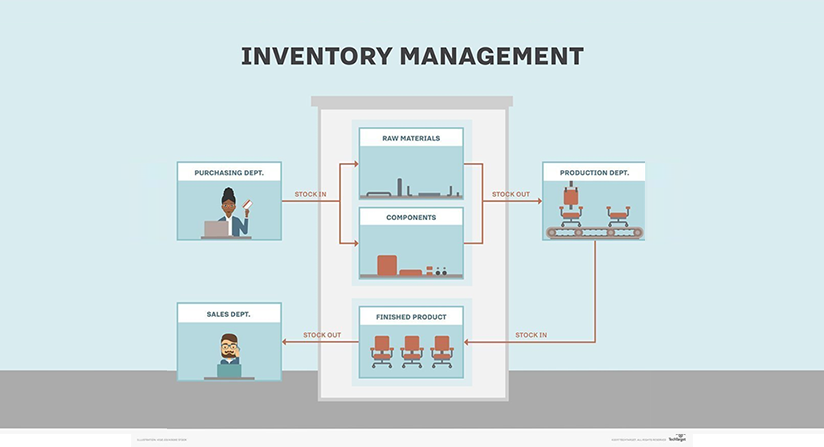

A Bill of Materials helps to make sure you have everything needed for production to keep it running efficiently. When you use BOMs, you are less likely to have too much or too little inventory. If your company subcontracts work to other manufacturers, providing them with a BOM also helps them to make sure they have the materials needed to manufacture your products and that you’ll receive them on time.

If Bill of Materials are not used, you may have shortages or overages, production could be slowed or halted, and you may end up paying more to have materials expedited. Without a BOM, workers may not have access to assembly instructions which could result in quality issues.

What Are the Advantages of Using a Bill of Materials?

There are many advantages to using BOMs. They help shop floor staff with step-by-step assembly instructions to minimize errors and improve customer satisfaction. BOMs help the procurement team to make better purchasing decisions by listing everything needed for upcoming orders. Bill of Materials keep production running smoothly and avoid downtime and delays which cost time and money.

BOMs include all of the parts needed for each product, which can be key to identifying faulty parts that result in product failures. Then you can quickly get replacements for those faulty parts and get production back on track.

What Are the Key Elements of a Bill of Materials?

Levels – If a product is very complex, it will have different BOM levels. These show the correct parts and instructions for each major component of the product. For instance, a refrigerator would have the freezer component, the refrigerator component, the door component, etc. If there is an ice maker, there could be another level for the door and for the freezer.

Part Number – Each component used in a product has a part number assigned to it and each part number is listed within the BOM. The part number may have some description in it to help identify it. For example, a lid may have the part number LID-721. This part number would be considered intelligent as it provides some information on what the part is. It is more challenging to use intelligent part numbers as they need a descriptor that can help to identify them, and whoever is creating them needs to have knowledge of each part.

Part Name – The part name is exactly that, the name of any particular part.

Phase – The phase lets you know where the part is in the product lifecycle. It could be in the design of the product (or, the “beginning”), the production (or, the “middle”), or when a product is discontinued (the “end of life”).

Description – A description gives more details about a part. So, if there are several parts that are similar, you can differentiate between them. For instance, if you manufacture cabinets, you may have cabinet handles that are of different colors or sizes that look similar and need to be defined.

Quantity – The quantity is how many of a part is needed. For instance, for assembling a side table, there may be two knobs included.

Unit Measure – If you have a part that needs to be measured, you need to indicate how much should be used. For example, if you manufacture chairs, you will need to indicate how many yards of fabric are required.

Procurement Specification – Some parts are made in-house, while others are assembled by a subcontractor or purchased from a vendor. The procurement specification indicates where these parts come from.

Reference Indicator – Electronics manufacturers often have parts that are included on a printed circuit board. The reference indicator shows where each part should be located on the board.

Notes – This is where you include any other information that would be helpful to those reading the BOM, such as an image, or suggestions of other vendors for ordering parts.

What Is the Structure of a Bill of Materials?

The structure of a BOM is based on either single or multiple levels. If a product has a single BOM, it is a simple product that is not difficult to assemble. Each part is only listed once along with the quantity. It is basically just a list of parts with some simple instructions.

For multi-level BOMs, the structure shows the order of BOMs from the first to be used at the bottom to the last on top. It contains assemblies, subassemblies, and components. A subassembly may require multiple components. Often when there are multiple subassemblies or components, they are indented to display the hierarchy of each procedure, and are thus referred to as Indented BOMs.

If a change is made to the assembly, it affects the subassembly and its components. In multilevel BOMs, the structure is often referred to as the “parent” for the assembly, and the “child” for the subassembly, as they are related to one another.

How Do You Create BOMs?

Know What You Want to Include – When you begin to create BOMs, you want them to be consistent. You need to think about what will work best. You should try to include any information that will help ensure all materials are available when needed – for instance, including often forgotten items such as adhesives.

Have a Central Point of Control – With different departments accessing the BOMs, you’ll want to be sure that there is a central location where they will be managed. If various systems are involved, you’ll need to ensure they connect so the BOM will be kept current as things change.

Assign an Editor(s) – You will need to have someone responsible for making changes to the BOMs. You can have multiple people, but the fewer the better to maintain greater control and avoid confusion.

Track Revisions – When things change in a BOM, you need to keep a record of the changes. The editors will need to have a type of audit trail, noting what changes were made and who made them so you can refer back as needed.

Multi-level or Single-level – Decide which type of BOMs, single-level or multi-level, make sense for each product.

Make the Most of BOMs With an ERP System

If you are a manufacturer with complex production processes, utilizing BOM software integrated with an ERP solution should be a serious consideration. ERP systems automatically track changes to BOMs and identify discrepancies that can occur when multiple departments, such as engineering and manufacturing, generate BOMs for the same product. To learn more about BOMs and manufacturing ERP, watch our Product Tour or contact us.

Follow Us