In our last blog post, we explored the differences between Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) and how together they help provide operational clarity. In this post, we’ll explore how ERP and MES integration can make your manufacturing business more agile.

MES software focuses on all of the processes happening in the production of products on the plant floor. It helps manufacturers with such things as reducing manufacturing cycle time, increasing employees’ productivity, and providing insight into any supply variances.

ERP software handles your business functions to include financial management, purchasing, inventory, sales and customer relationships, and analytics and reporting. An ERP system helps your manufacturing company by providing control over your business focused operations.

With MES ERP integration, the functionality of MES shop floor control with ERP business process control is combined. This powerful combination can help your manufacturing business fine-tune its operations to become more agile and responsive to changing demands.

ERP and MES: The Relationship Explained

Manufacturers are becoming more competitive day by day. From adopting lean manufacturing strategies to investing in power-driven machinery, manufacturers try to deliver the best quality products in the shortest period possible.

What is MES software?

Manufacturing Execution Systems (MES) is software that controls complex manufacturing operations and data on the shop floor. MES software helps to improve the quality of the production process so manufacturers can easily respond to shifts in demand and customer preference.

What does MES software do?

A Manufacturing Execution System allows businesses to track, monitor, and collect accurate data about the production cycle. MES can be integrated with business process systems and ERP software to provide organizations with deep views of their production capabilities.

A well-rounded and powerful MES software facilitates:

- Product tracking: A range of features in ERP ensures proper tracking of products on the shop floor.

- Data collection: Making informed business decisions becomes easier using the reports, dashboards, KPIs, and other analytical tools offered by MES. Get real-time data about shop floor, labor, scrap, and other resources to schedule production runs and manage machine maintenance/upkeep.

- Management of resources and quality control: With MES, you can track your employees’ productivity and quality of work remotely to quickly make adjustments as needed.

What does ERP software do?

Enterprise Resource Planning (ERP) solutions provide a backbone to an organization by streamlining the flow of communication across every department. From accounting and finance to warehouse management, inventory, sales, purchasing, and reporting, ERP can manage every department, offering real-time data access and visibility to users.

ERP systems allow the organization to standardize and automate key business practices, gain visibility into mission-critical practices and operations, and manage company resources on a single platform.

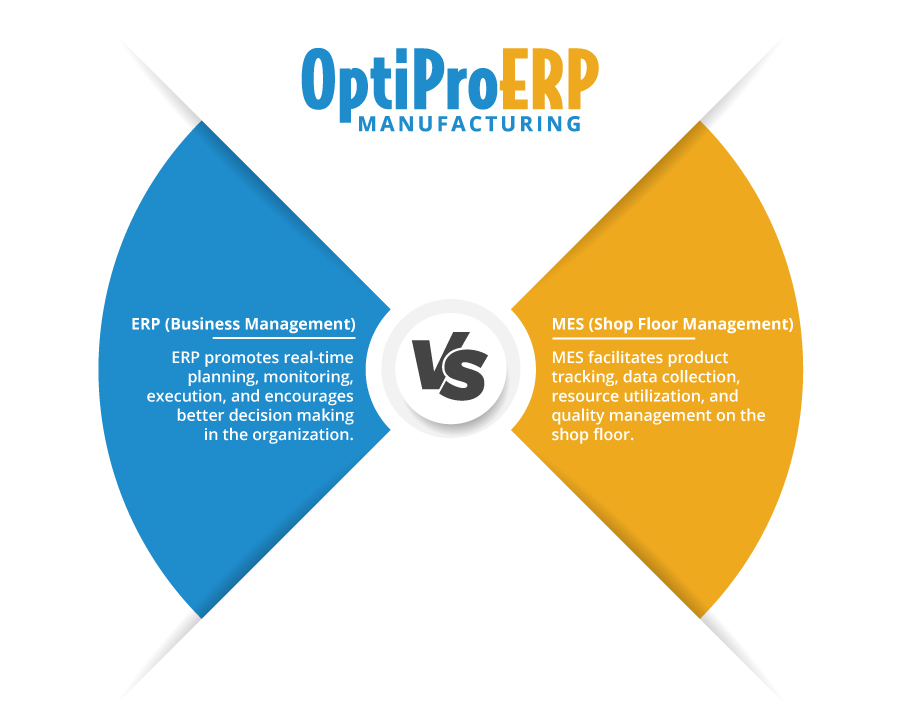

Core competencies of ERP vs MES

ERP provides enhanced customer service through greater connectivity; smarter decision making with end-to-end visibility; better planning, monitoring, and execution with real-time data; and lower costs with increased control.

MES provides product traceability, dynamic production scheduling, connectivity of manufacturing operations to the back office, quality management at all levels, and optimization of shop floor operations and resources.

Why do I need MES, if I already use ERP?

Large manufacturing organizations rely on ERP to manage multiple aspects of their business. However, generic ERP leaves many gaps in managing shop floor execution and resources (machines and humans) however manufacturing ERP includes MES as a vital element.

Integrating ERP and MES enables your business to utilize the core competencies of evolving technology. Tasks such as scheduling machines and ensuring traceability via batch management are all handled by MES software. MES allows manufacturers to connect manufacturing operations to the entire company.

ERP is about “Why”, MES is about “How to”?

MES feeds ERP with timely information, such as parts and serial number usage, information about production levels, scrap material, and more. Integrating cloud MES software and ERP encourages accurate demand forecasting helping organizations reduce inventory by avoiding overproduction.

5 ways ERP and MES integration can make manufacturing agile:

1. Achieve accuracy in demand forecasting

Insufficient inventory will delay deliveries and reduce customer satisfaction hurting your company’s bottom line and reputation. Similarly, excess inventory ties up cash flow that could be used to advance your business through important investments in such things as new machinery or technology.

Collaboration between ERP and MES software coordinates operations on the shop floor with customer service, logistics, and delivery to more accurately forecast demand so you can keep inventory at the right levels. Knowing the appropriate amounts of stock needed also ensures there is no employee or machine downtime due to the inability to produce orders. With the ability to keep on top of inventory needs you can easily pivot to meet consumer demand with insight into customer trends.

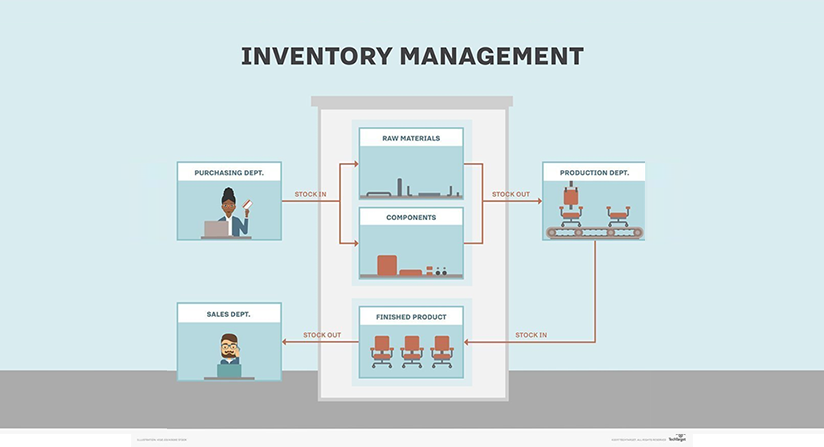

2. Better manage inventory with JIT delivery

Just-in-time (JIT) delivery allows manufacturers to receive inventory when it is needed to avoid having supplies of inventory sitting around using up space and incurring the carrying cost of stock that is not ready for use. By having vendors deliver supplies as they are needed, you reduce overhead and lower the cost of doing business.

With ERP-MES system integration, you can more efficiently manage inventory by having sales and service coordinated with manufacturing to understand supply needs and reduce expenses. In turn, the savings can be passed on to customers to improve your competitive advantage and market share. By keeping close tabs on inventory needs you can quickly adjust supply orders as demand dictates.

JIT delivery can also help you understand when additional employees are needed on the manufacturing floor and allow you to free up warehouse space to expand manufacturing operations. JIT delivery adds customer value with a more flexible workforce that can better focus on quality, and with lower overhead that can make products more affordable.

3. Avoid rush orders and production delays

Rush orders are a big risk that supply chain managers sometimes are forced to take. With rush order transactions, delivery of needed material, creation of customer orders, and deliveries all happen on the same day. This situation is challenging because there is so much opportunity for things to go wrong. The supplies might not arrive on time or they might not be available, employees might make errors due to the quick turnaround, or a machine might have issues causing a delivery delay.

MES and ERP integration allow you to avoid rush orders by knowing when to reorder from suppliers before inventory falls below a set level. Having greater control over supply needs minimizes production delays and errors, and eliminates the rush delivery fees.

4. Achieve real-time visibility into quality issues

MES and ERP integration allow you to see what is happening in the production process in real-time to handle problems immediately. Supplies can be tracked and quality issues can be noted quickly so faulty material can be returned to the vendor upon inspection to eliminate scrapping of material. ERP with MES software also helps to avoid the possibility of liability from product defects and it monitors machinery so any maintenance needs are predicted to adjust workflow accordingly.

Real-time visibility with ERP and MES software helps you to produce better quality products and achieve a greater competitive advantage.

5. Gain greater productivity with increased connectivity

Connectivity to smart machines on the shop floor ensures efficient and leaner manufacturing by planning an adequate quantity of goods for production. This access brings back-office and front-office executives onto the same page, leaving little room for error or misinterpretation. This communication between systems can increase productivity and ensure optimal uptime, promoting the present and future growth of the business.

The future of ERP and MES

Considering the pace at which technology is evolving, the manufacturing industry is on track to grow enormously. Moving forward, MES integration with ERP will be more modular, cloud-based, and connected to all sorts of devices through the Internet of Things (IoT).

Industry 4.0 promotes wireless sensor and actuator networks for in-progress production adjustments. RFID tags are widely used on the shop floor to track work-in-progress goods and manage the utilization and availability of assets. A modern ERP and MES system can utilize this new technology to stay on top of all manufacturing processes.

The relationship between ERP and MES

Organizations should understand their business requirements and then select a full-fledged software solution that can automate key business processes. ERP software is used by modern organizations, whether large or small-scale. It manages the entire organization, but production is not a part of ERP modules. On the other hand, MES primarily focuses on the production/shop floor functions. So, it is better to have MES embedded in ERP to manage shop floor processes seamlessly for greater business agility.

If you are looking for an intelligent ERP with embedded MES shop floor control functionality, visit www.optiproerp.com.

Follow Us