What is inventory visibility?

Simply put, inventory visibility is knowing how much inventory is available, at what location, and at any given point in time. Whether in transit, in a warehouse, or distribution centers, you need to know inventory levels at all locations.

What are the benefits of inventory visibility?

1. More accurate forecasting

When stock is optimized in the right manner, routine inventory audits are done on time with inbound, outbound, warehousing, and in-transit movements tracked meticulously. Forecasting becomes sharper and distribution is better planned.

2. Smarter resource allocation

Inventory ties up money and should be kept at the lowest possible levels. Inventory visibility ensures your capital is not sitting on warehouse shelves and that it is being used in your operations.

3. Increased efficiency and better use of employee time

Manual inventory tracking takes multiple resources and lots of employee time. Automatic tracking of inventory levels as transactions occur increases efficiency, frees up staff to work on other activities, and enhances business performance.

4. Reduced stock levels

Stock-out and overstock can lead to dissatisfied customers and tied-up capital. Inventory visibility helps keep stock levels optimized to meet customer demand, keep costs down, and improve warehouse organization as stock is more efficiently managed.

5. Greater supply chain transparency and increased demand fulfillment

Inventory visibility is one of the most critical management tools of manufacturing as it boosts profitability. In some organizations, inventory is located in many locations to include distribution centers, warehouses, store shelves, backrooms, etc. It’s important to know the quantity available at each location to eliminate inventory waste costs.

Inventory visibility monitors orders and constantly updates the supply chain to meet promised deadlines. Having inventory reconciled to meet demand results in increased profitability and customer satisfaction.

5 Ways ERP Helps You Meet Production Requirements

1. Resolves unpredictable scenarios

- Enterprise Resource Planning (ERP) software promotes automated processes and integrated production functionality. It synchronizes production, sales, financial management, and warehouse management and automatically tracks the movement of every inventory item.

- Reporting functions yield accurate insights and data is updated in real-time. As per SAP Performance Benchmarking, manufacturing organizations that use SAP Business One experience an 8% increase in plan adherence.

- ERP integrates material availability data with delivery dates and real-time manufacturing conditions. This can significantly enhance customer satisfaction and cost-efficiency. With the supply chain visibility tools that ERP offers, decision-makers can resolve issues without delay. Visibility improves transparency in complicated supply chain networks and the quality of products and services offered.

2. Enhances just-in-time inventory strategies

- ERP eliminates the need for manual scheduling and promotes a just-in-time (JIT) inventory strategy. Materials are ordered and received to meet production requirements saving inventory overhead expenses and increasing efficiency.

- ERP enables real-time inventory visibility, tracking, and data management.

3. Allows better inventory levels and improves customer relationships

- Get insight into point-of-sale online transactions, shipping data, and procurement and production data, all on a single screen. This enables data-led decision-making which nurtures relationships with customers and vendors.

- With real-time dashboards, businesses can view the inventory status at different plant locations, warehouses, stores, etc.

- ERP provides the functionality to monitor trends to ensure you meet customer demand on time. This develops a loyal client base and increased profitability.

4. Drives omnichannel growth

- Manage inventory across multiple locations and channels

- Receive sales orders from multiple sources and automate the process

- Promote cross-channel inventory movements

5. Provides actionable insight

- Analyze global financed and rolled-up data with user-configurable reports and dashboards

- Ensure optimum stock levels using material requirement planning functionality

- Better decision-making with data at your fingertips

Conclusion

SAP Business One, one of the renowned ERP software systems for small and mid-sized businesses, effectively balances inventory management and sales orders for better business growth. SAP Business One is the platform upon which OptiProERP is built.

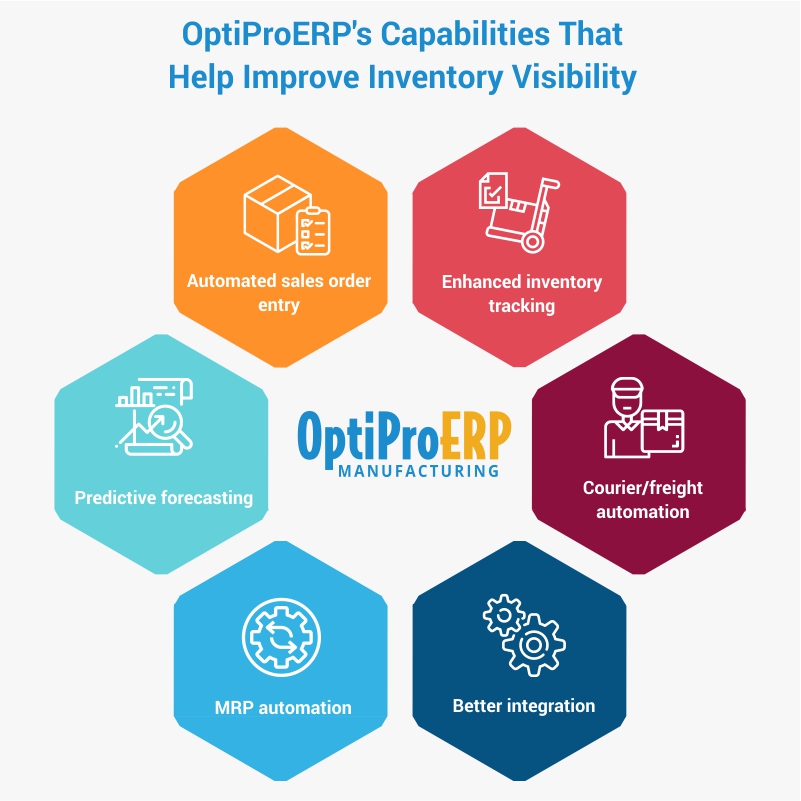

OptiProERP with SAP Business One helps improve inventory visibility to your supply chain with:

- Automated sales order entry – ensures that sales orders are linked to real-time inventory data

- Enhanced inventory tracking – lets you track when inventory is procured, moved, or sent out of the warehouse

- Courier/freight automation – integrates your technology with courier companies or freight specialists

- Better integration – Inventory, Finance, Sales, Procurement, Accounts – every department is integrated for greater insight.

- MRP automation – receive detailed information about product requirements. Order recommendations are designed for timely delivery.

- Predictive forecasting – encourages stock visibility and lets you predict stock levels to meet customer demand.

To learn more about inventory management and supply chain visibility solutions, please feel free to contact us.

Follow Us