MRP application synchronizes the flow of materials in a deadline-driven order system that is aligned with the production schedule.

Material Requirements Planning (MRP)

ERP software for manufacturing and distribution

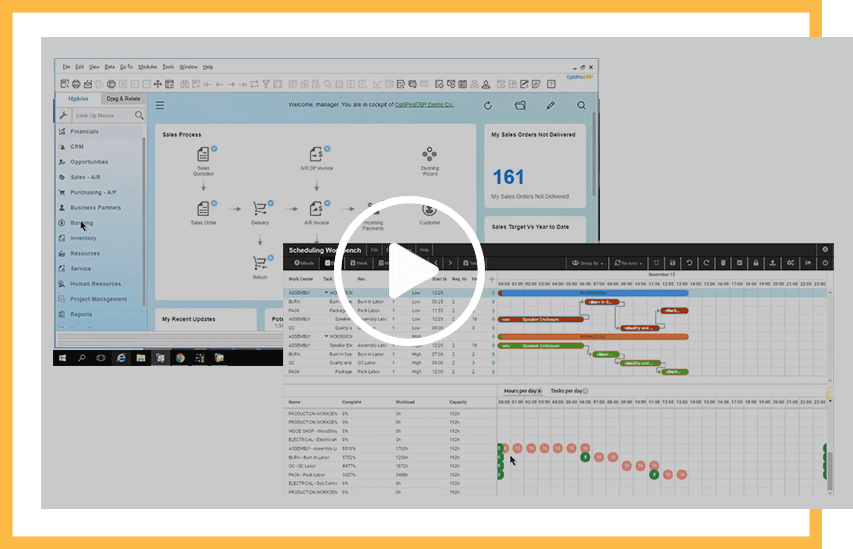

From sales order to shipping and every step in between, OptiProERP’s Material Requirements Planning (MRP) software helps manufacturers operate more efficiently and more profitably.

MRP Software from OptiProERP

MRP software from OptiProERP will help you succeed in key areas like these:

- Customer retention: Deliver on time, every time.

- Cost reduction: Lower inventory carrying costs.

- Productivity: One view of all demand-driven activities.

MRP application synchronizes the flow of materials in a deadline-driven order system that is aligned with the production schedule.

MRP software from OptiProERP will help you succeed in key areas like these:

- Customer retention: Deliver on time, every time.

- Cost reduction: Lower inventory carrying costs.

- Productivity: One view of all demand-driven activities.

Benefits of OptiProERP's MRP Software

Forecasting

Predict inventory demand by sales orders, minimum stock requirements or recurring seasonal orders.

Global Planning

Manage multi-site distributed demand from a single dashboard and reduce costs with bulk purchasing.

Inventory Management

Utilize on-hand stock efficiently to reduce purchasing costs, minimize order lead times and receive materials on time.

Easy-to-Use MRP Software from OptiProERP

Mobility matters in today’s 24/7 world

Access the system from anywhere, on any device, tablet or smart phone.

The central MRP screen shows all supply and demand information. The user-friendly display identifies all of the materials that need to be produced or purchased to maintain minimum stock levels or to fulfill sales orders.

Combining convenience and efficiency, planners may also run and refresh manufacturing and purchasing plans tied to optimal inventory availability that aligns with the Master Production Schedule.

How OptiProERP’s MRP Software Works

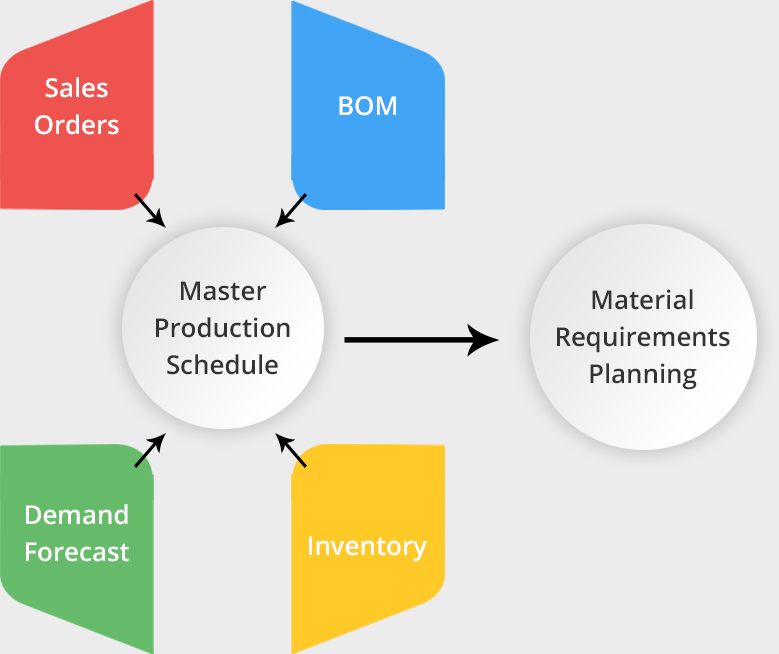

The Master Requirements Planning (MRP) logic engine collects information received either directly from sales orders or from a demand forecast.

MRP also receives input from the Master Production Schedule (MPS) about the quantities of finished products that must be produced to fulfill either a sales order or to meet the demand forecast.

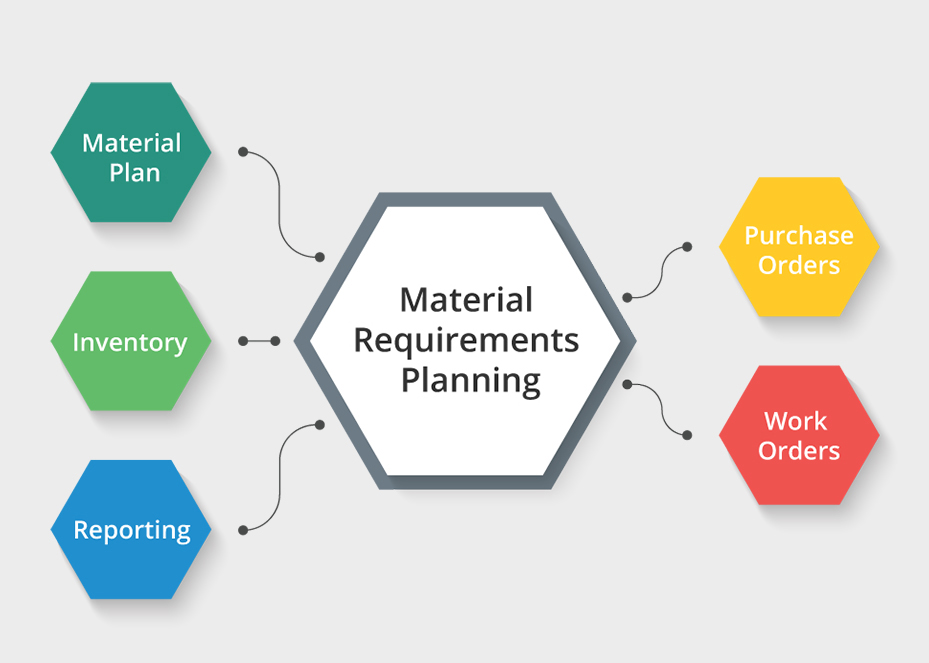

What OptiProERP’s MRP Software Does

Based on information input from other ERP modules, the MRP application produces outcomes like these:

- Populates orders and reports

- Quantity requirements

- Run scenarios

What OptiProERP’s MRP Software Does

Based on information input from other ERP modules, the MRP application produces outcomes like these:

- Populates orders and reports

- Quantity requirements

- Run scenarios

OptiProERP’s Material Requirements Planning Processes

OptiProERP’s Material Requirements Planning Functionality

Material Requirements Planning (MRP)

Material requirements planning (MRP) consolidates demand, scheduling and inventory requirements into a single view for manufacturing and purchasing requirements.

Master Production Scheduling (MPS)

Works with projected and actual supply chain demand to create production, purchasing and inventory schedules.

Demand Forecasting

Forecast inventory demand by sales order, historical sales patterns or to meet minimum stock requirements.

Operational Capacity

Working backward, the planning engine automatically calculates materials, resources and capacity needed to complete each step.

Capacity Resource Planning

Working within predefined operational capacity, the Resource Planning tool allocates work based upon the available capacity of available resources.

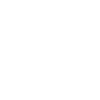

How to Know if You’re Ready for Material Requirements Planning Software

If questions like these are keeping you awake at night, you’re ready for OptiProERP’s Material Requirements Planning software.

See how OptiProERP meets your unique needs