Did you know:

- 90% of manufacturing leaders see a positive relationship between their performance and the sustainability transformation of their organization?

- 84% of consumers claim sustainability is a key consideration when making a purchase decision?

- 62% of global Co2 emissions come from manufacturing sectors?

- 54% of global energy consumption is from the manufacturing and production sector?

Gone are the days when manufacturers were dealing with localized and simple issues. Now they are grappling with more complex and global challenges, including supply chain disruptions, scarcity of resources, climate change, and a shifting regulatory environment. To combat these challenges, modern manufacturers are focusing on critical areas including the sustainable optimization of resources and processes across the supply chain, implementation of circular innovation to meet sustainability demands, and utilization of advanced technologies for the automation of the factory floor and the overall business.

Why is Resilience Important for Manufacturers?

Many manufacturers want to make their businesses more resilient, but few know how to do so. The coronavirus pandemic has become an eye-opening reminder of the magnitude and speed with which events can inflict harm on the global system, especially when resilience is not in place. The capability of businesses to manage stress, recover critical functionalities, and thrive in changed circumstances is defined as resilience.

Resilience does not mean just operating and surviving in the present scenario. But it is more toward building improved operations and processes for a better future. As the manufacturing sector moves towards economic recovery, resilience has become very important for manufacturers in today’s unpredictable and dynamic business environment. To operate in a secure, resilient, and sustainable manner, manufacturers need a strong culture and digital modernization.

What is Sustainability and Why Is It Important?

Sustainability is the ability to create, develop, and exist without hampering natural resources and by conserving them for the future. Sustainable manufacturing, also referred to as green manufacturing, has received attention for its ability to help reduce climate change and there is increasing pressure on manufacturers to adopt green practices.

With climate change an important concern, there is an increasing worry about the impact of heavy industry on the environment. Manufacturers are recognizing that implementing sustainability also reduces waste and improves the use of energy, water, and raw materials, which lowers costs. Moreover, sustainability helps manufacturers meet industrial and governmental regulations to reduce the risk of costly audits. Sustainable manufacturing includes:

- Reducing emissions and pollution

- Avoiding harm to the local environment

- Cutting raw materials and resource waste

- Increasing safety for workers and nearby communities

- Reducing the consumption of water, energy, and other limited resources.

Types of Sustainability

Human sustainability is to improve human capital in society. Investments in nutrition, skills, knowledge, health, education and access to services all fall under human sustainability. Human sustainability focuses on skills development and human capacity to support the sustainability functions of the organization and to promote the well-being of society.

Environmental sustainability involves reducing water use, wasteful processes, and the carbon footprint of manufacturers. Positive change in these areas not only helps with environmental sustainability but can also lead to lower costs.

Economic sustainability provides incentives for businesses while adhering to sustainability guidelines. Businesses should strive for a sustainable approach to generate profits.

Social sustainability is about protecting people’s health by having good working conditions, eliminating pollution, and providing access to resources without compromising fair pay policies and the overall quality of life. It also involves educating people on sustainability.

How Can Digital Technology Be an Enabler of Resilience and Sustainability?

For manufacturers, digitization, and resilience go hand in hand. Embracing data and empowering the workforce with the relevant skills can be a great idea to achieve manufacturing sustainability. Technology can be used to automate and optimize time-consuming manual tasks, providing more time to employees for value-added work. Manufacturers also need to build a partnering ecosystem within the industry with digital technology companies and other sectors to build robust supply chains and drive new business innovations. For example, British manufacturers united to produce over 20,000 ventilators in just 12 weeks, down from 20 years, with the help of technological innovation. Adopting digital modernization can help manufacturing businesses quickly adapt to the dynamic needs, external circumstances, and expectations of an increasingly digital workforce.

How Can Manufacturers Build Resilience and Become Sustainable?

1. Leveraging automation for sustainable operations

Keeping manufacturing sustainability top of mind is one thing, and implementing everyday sustainable processes is another. It is imperative to weave sustainability practices across the supply chain. Manufacturers should consider innovative methods of optimizing resources and processes. Automation creates valuable data insights that improve productivity and efficiency. According to SAP Insights, over 44% of manufacturing leaders are considering process automation to improve operational efficiency and strengthen the supply chain.

2. Create an agile supply chain

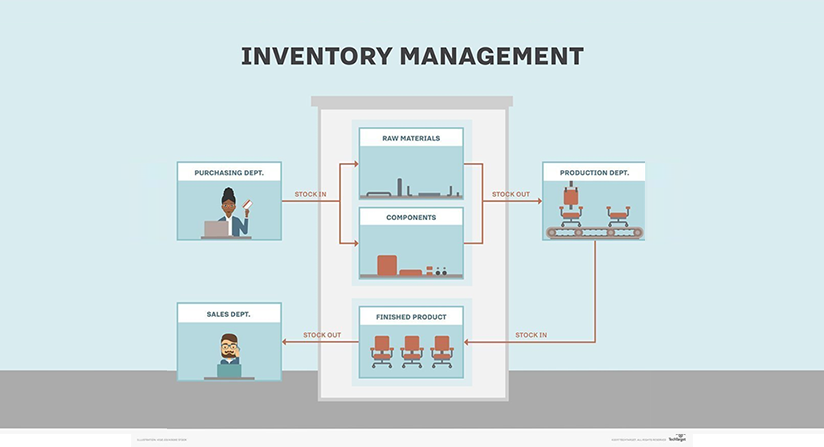

A connected supply chain helps improve planning, enhance visibility, predict disruptions, and maximize the productivity of assets with embedded data intelligence and real-time visibility. Businesses are also adopting sustainable circular supply chains that help reduce waste and supply continual resources.

3. Build the right culture for resilience

Whether working in the office, on the plant floor or remotely, employees should be empowered to drive resiliency. Resiliency not only helps the organization leverage digital technologies, but it also helps to build business value and sustainable innovation. Manufacturing businesses that have the right digital technology, accurate data, and an agile culture can maximize the impact of sustainability. An ERP solution can help build technology competencies to increase resilience and sustainability.

4. Embrace the data revolution

Whenever shop floor equipment is idle, it costs manufacturers money. When factories first developed, big data was not available, and intelligent packaging did not exist. Even if the data had been available, manufacturing plants did not have the technological capabilities to harvest and collect the relevant information. Now, that scenario has changed. Large amounts of data are available in manufacturing and can be processed quickly to achieve higher productivity and efficiencies. Critical data that helps identify market demand can be easily harvested. When manufacturing data is fully utilized the production manager can view available resources and the status of manufacturing and the sales manager can see in real-time how many products were sold. This data intelligence empowers companies to make production adjustments quickly to help achieve manufacturing sustainability.

5. Personalize customer relationships

To be resilient and become sustainable, it’s important to meet customers’ expectations in new ways. Connecting data silos and gaining customer behavior insights can improve service throughout the customer relationship cycle. Artificial intelligence technology can also be leveraged to predict and improve customer relationships. Manufacturing companies can understand patterns of product usage through customer insights. It allows them to provide better post-sales support and improve sustainable innovations.

6. Unlock your people’s potential

People play a very important role in manufacturing. Job duties may shift but human imagination and creativity are the major innovation drivers. Smart manufacturing has made jobs more relevant and interesting by automating mundane tasks and allowing employees to be more creative and evolve their capabilities. These changes have led to increased employee productivity and growth, and improved sustainability. Using smart manufacturing practices, businesses become more future-ready.

Get Started on Building Sustainable Production

Sustainability started to meet compliance requirements and soon became a strategic imperative for manufacturing businesses. Now, sustainable operations are one of the biggest drivers of transformation and a major source of competitive advantage. Manufacturers that embrace sustainability discover new opportunities for innovation. By collaborating with stakeholders and focusing on long-term outcomes, manufacturers can leverage significant benefits on the road to sustainability ranging from improved efficiency and competitiveness to reduced business risks and costs.

To speed up the process of becoming sustainable, it can be a good idea to partner up with an experienced technology consultant. A technology partner can provide a framework assessment to identify low-hanging fruit that can help you attain manufacturing sustainability goals. They can also help you address change management and security concerns.

Are you ready to adopt resilience and sustainability? Now is the time to think about how your manufacturing business can create greater long-term social, human, economic, and environmental value. Connect with our manufacturing experts on how to help your business achieve sustainable business growth.

Follow Us