A Manufacturing Execution System (MES) is an information system that connects, monitors and controls complex manufacturing systems and data flows on the shop floor. The main goal of an MES is to ensure the effective execution of manufacturing operations and to improve production output.

An MES helps achieve that goal by tracking and gathering accurate, real-time data about the complete product lifecycle, beginning with order release until the product delivery stage for finished goods.

The MES collects data about product genealogy, performance, traceability, material management, and work in progress (WIP), and other plant activities as they occur. This data, in turn, allows decision-makers to understand the current situation of the factory floor and better optimize the production process.

Digitally controlled and monitored workplaces nurture an increased bottom line. In a manufacturing company, tracking and capturing the entire business data is paramount.

A Manufacturing Execution System offers tools for the execution phase in the production process. Specifically, the period between when a production order has been released to the production floor and until the work is completed.

While the key task of MES is the ability to have an intuitive and easy way of starting and reporting back on production jobs, it also supports the daily planning happening on the shop floor, this includes prioritization of one job over another, assigning jobs to resources where resources are either individuals or groups of workers or individual or groups of machines or even in some cases vendors operating on part of the production process.

Workers should not be confused with large numbers of jobs and functions. With an easily configurable terminal, companies have the option of setting up dedicated terminals showing only jobs assigned to a specific worker, showing only jobs assigned to a given subsection of the production floor, and perhaps showing only functions relevant for the type of work being performed around that particular terminal. These could be those functions accessing the details of a worker’s schedule, flex hours, etc. which are only available in the break rooms while core production functions are available only on the production floor.

Increasing the efficiency of shop supervisors is equally important. Manufacturing Execution shop supervisors receive tools that decrease the number of times they would have to use in an office. Enabling the shop supervisor to quickly execute tasks such as job reprioritization, reassignment, materials availability, and absence registrations allows for the least disruption in the day-to-day operation.

As the day passes and accumulated registrations come in from the production floor, the enterprise will have a far more accurate picture of the current state of the production process with an immediate understanding of produced quantities and the cost incurred.

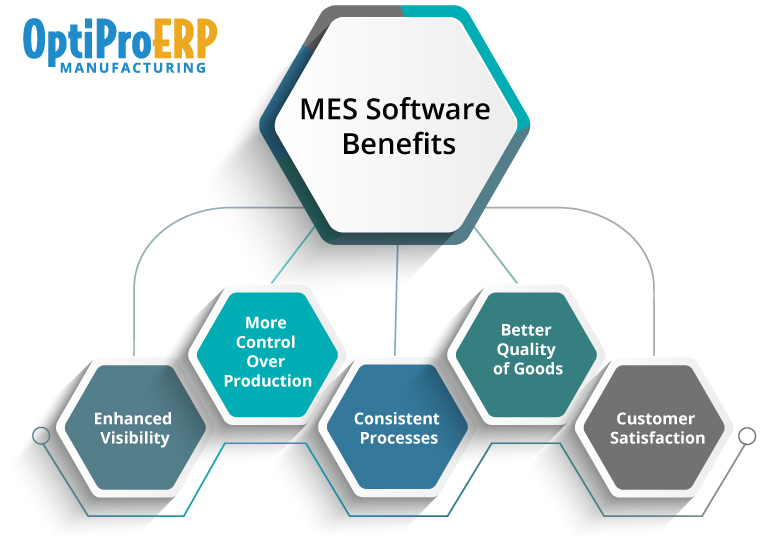

The reasons to invest in a Manufacturing Execution System (MES) software are many. Listed below are a few of the critical reasons –

- Enhanced visibility and more control over production

MES ensures proper production optimization by giving supervisors access to real-time information. This includes the current state of the equipment in use, product trials, availability of resources, etc.

- Consistent processes

A full-fledged MES ensures consistency. Once an operation is performed, personnel can track it for improved security. Replacing paper-based documents, eliminates data redundancy, loss, and duplication.

- Better quality of goods

Even in a controlled business environment, undesired events can happen which may hamper the quality of final goods. MES ensures procedural enforcement to sustain shop floor efficiency.

- Meet customers’ requirements

When you ensure the quality and consistency of processes, it automatically enhances customer satisfaction.

- Integration of the comprehensive business processes

MES is an add-on that standardizes the entire business operations with its top-notch functions. Shop floor personnel can execute, track, and record activities. This allows the supervisor to make prompt decisions.

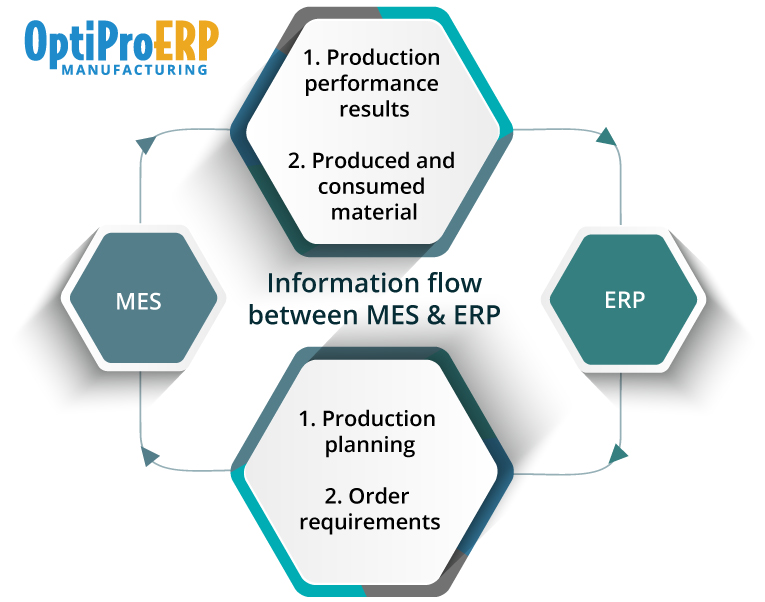

Information flow between MES and ERP:

MES is an intensive system with multifaceted shop floor execution capabilities. It serves as a functional layer, allowing manufacturers to work efficiently in real-time. MES depicts many advantages for manufacturers; below are the top five advantages outlined.

- Less waste and expense

MES includes digital master logs and device history records. Now, you don’t need to store, file, and spend the time to track the paperwork completed on the shop floor. This saves time and effort made during data entry.

MES creates a streamlined work environment. It reduces scrap by maintaining product capacity and detecting inconsistencies. For example, MES captures labor, tooling, scrap, downtime, and other expenses directly from the shop floor. Its capability improves the operator’s speed and efficiency so they can manage the shop floor data transactions and documentation easily.

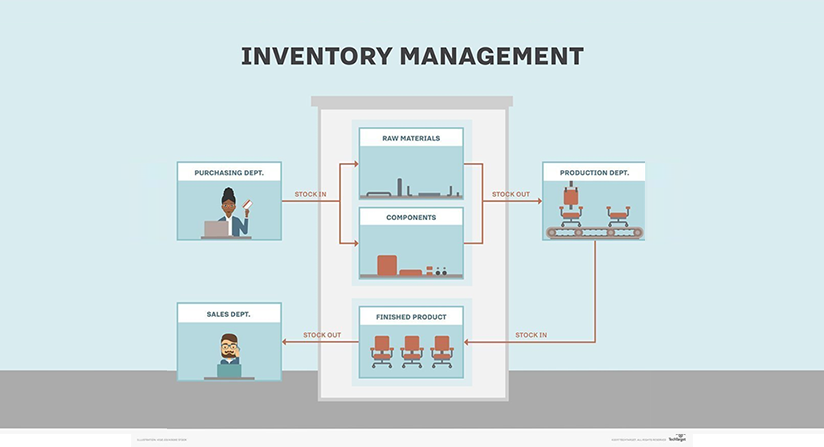

- Minimize inventory

For every organization, a sizeable inventory means a huge expense. When you include a Manufacturing Executive System in the organization, it ensures the specific amount of materials needed for the subsequent future. This allows businesses to save time, effort, and inventory expenses. MES also minimizes the excess inventory by encouraging the just-in-time inventory strategy.

- Better traceability

If you have MES integrated into your ERP system, it can link lot numbers from raw materials to the work-in-progress items with finished goods.

In this way, the operators and supervisors can document/track the tasks better to avoid chaos and enhance traceability. It will also improve quality compliance. MES is an efficient tool that provides mission-critical production information across the manufacturing company and supply chain.

- Decreased downtime

Equipment downtime is an empirical state which usually every enterprise faces. When machines don’t work effectively and are not maintained properly, it’s hard to make money in any manufacturing company. So, how can MES help you with increased uptime? MES includes integrated scheduling and maintenance. This means that the task will only be initiated when the right tooling is ready, machines are maintained well, and source inventory is available.

MES vs ERP

In traditional ERP software, under a single big umbrella, modules like finance, sales, purchasing, inventory management, and many other business processes make the entire enterprise more efficient.

While a stand-alone MES software is focused almost only on the shop floor, helping keep production in line with demand and supply. MES is increasingly available as a module within an ERP system, though can also be used as a stand-alone system integrated with ERP software.

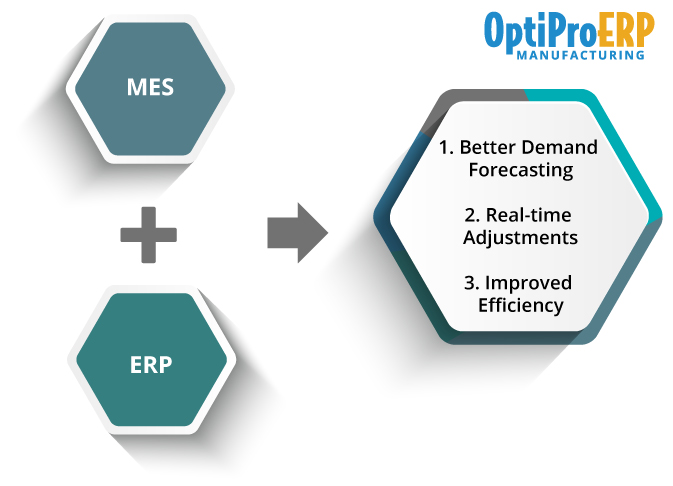

Integration of MES and ERP

Integrating an Enterprise Resource Planning (ERP) system and Manufacturing Execution System MES module enables organizations to achieve the goal of streamlined manufacturing. This is because these two systems complement and enhance each other’s efficiency.

As a single unified system, there are multiple possibilities for improved flexibility and efficiency. Here are a few key examples.

- Better Demand Forecasting

Using fully integrated systems, demand changes that are recorded in ERP systems can be fed into manufacturing schedules to ensure that the quantities of products manufactured are more closely aligned with demand.

- Real-Time Adjustments

Better system integration supports more efficient execution of change orders. New manufacturing processes that impact production times and costs can be shared immediately with enterprise systems so that any pricing or product delivery information can be updated. Likewise, any product changes requested by customers can be transferred to production systems as soon as possible to avoid delays in fulfilling orders.

If there is a quality issue on the floor, real-time notification to the business systems can be made to take the necessary corrective action as soon as possible. When defective material is detected, it can be quickly removed from the inventory and returned to the supplier for a replacement or refund. The manufacturer saves money by eliminating scrap due to defective raw material and also reduces exposure to recalls and possible liability issues.

- Improved Efficiency

The exchange of real-time information between the business layer and the production layer can increase overall equipment efficiency (OEE), reduce cycle times, and provide management with greater visibility for improved decision-making. The accuracy of the information and the speed with which it can be delivered due to ERP and MES integration allows for more nimble and lean manufacturing, the goal of every organization that wants to keep a competitive edge.

Summary

A Manufacturing Execution System monitors work-in-progress (WIP), encourages increased uptime, greater efficiency, prevents errors, and improves shop floor visibility.

It supports electronic record-keeping and ensures that unified information is cascaded throughout the entire organization.

Presently, manufacturers are including connected devices, the Internet of Things, and other state-of-the-art technologies and devices which increase operational efficiency. An MES software also allows you to integrate shop floor devices to improve the speed of work. During lot processing or dispensing of goods, an MES solution lets you track and record the data.

Why use disparate systems to manage distinct operations when you can do more with a comprehensive manufacturing ERP solution?

And like Henry Ford said, “If you always do what you always did, you’ll always get what you’ve always got.”

To learn more, please visit our website or send an email to optiproinfo@optiproerp.com.

FAQs

What is MES module?

Manufacturing Execution System (MES) can be integrated into ERP software to optimize the manufacturing processes. MES functionality is designed to help manufacturers monitor, track, and document and control the entire production lifecycle and improve quality control function. MES module reduces inventory carrying costs and increases uptime.

What are the basics of MES?

MES software provides a detailed view of production status, dispatch, sequencing, traceability, performance analysis and more. It allows for real-time, minute-to-minute resource scheduling.

Core functions of MES include:

- Provides integrated dashboards to monitor and report plant performance

- Supports execution of production orders from release to finished goods

- Automatic data collection through equipment and sometimes manually to drive quality , compliance and measure efficiency

Follow Us