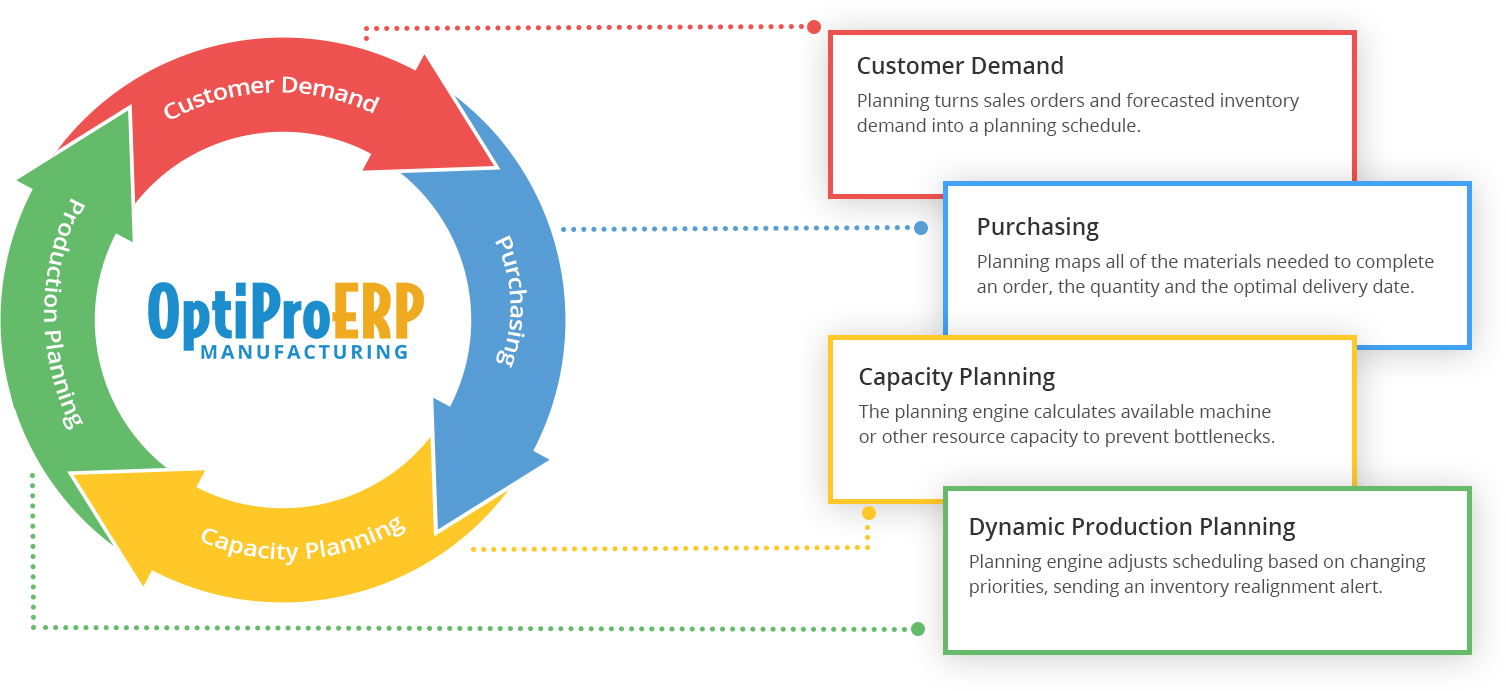

OptiProERP’s Advanced Planning and Scheduling (APS) is seamlessly integrated within its manufacturing solution to maximize your production processes and keep them flowing smoothly. OptiProERP’s APS helps manufacturers balance demand, capacity, and constraints to generate achievable production schedules.

Advanced Planning and Scheduling

ERP software for manufacturing and distribution

OptiProERP’s Advanced Planning & Scheduling simplifies and enhances the orchestration of your manufacturing processes through robust planning and scheduling capabilities

Why Choose OptiProERP’s Advanced Planning & Scheduling Software?

OptiProERP’s APS enables manufacturers to:

- Plan: in finite or infinite capacity mode with multiple or no constraints to make better planning decisions

- Schedule: interactively with multiple or no constraints and digitally generate, modify, update, and visualize production schedules to meet your needs

- Optimize: according to easily configurable business objectives, such as minimizing changeover times and other schedule-optimizing priorities

- Visualize: production schedules, current load, resource capacity, bottlenecks, ‘what if’ scenarios, the impact of changes, and compare alternatives

- React: quickly and intelligently to expected and unexpected changes to your production and update your production schedules digitally

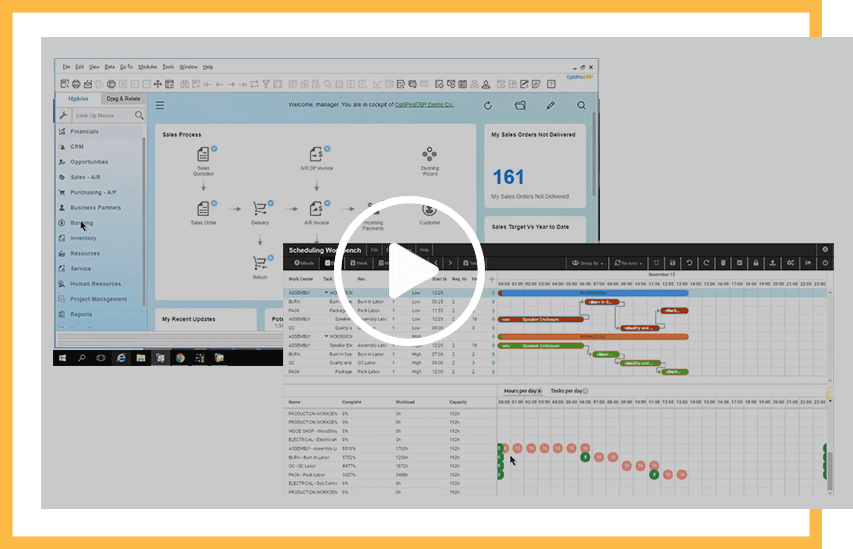

See More of OptiProERP in Action

How you can streamline your manufacturing and distribution business with OptiProERP

Why Choose OptiProERP’s Advanced Planning & Scheduling Software?

OptiProERP’s Advanced Planning and Scheduling (APS) is seamlessly integrated within its manufacturing solution to maximize your production processes and keep them flowing smoothly. OptiProERP’s APS helps manufacturers balance demand, capacity, and constraints to generate achievable production schedules

OptiProERP’s APS enables manufacturers to:

- Plan: in finite or infinite capacity mode with multiple or no constraints to make better planning decisions

- Schedule: interactively with multiple or no constraints and digitally generate, modify, update, and visualize production schedules to meet your needs

- Optimize: according to easily configurable business objectives, such as minimizing changeover times and other schedule-optimizing priorities

- Visualize: production schedules, current load, resource capacity, bottlenecks, ‘what if’ scenarios, the impact of changes, and compare alternatives

- React: quickly and intelligently to expected and unexpected changes to your production and update your production schedules digitally

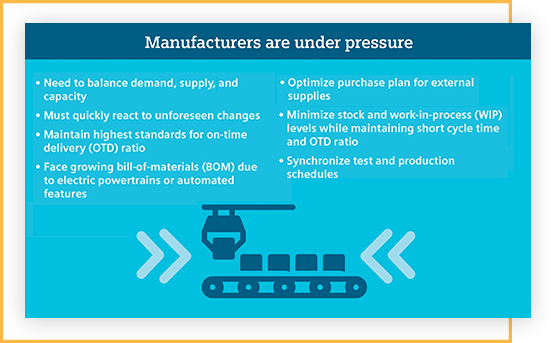

Production Challenges Manufacturers Face that a Good Planning and Scheduling Tool Helps Solve

- Demand, supply, and capacity not in balance

- Changes in lead times, customer demand, and the supply chain

- Longer delivery times and getting products to customers on schedule

- Production bottlenecks, idle time, and resource inefficiencies

- Disconnected demand, purchasing, and production planning

- Reacting slowly to deviations from the production plan and schedule

- Little insight into manufacturing processes, tasks, and disruptions

- Inadequate visibility to make better planning and scheduling decisions

- Inability to react to expected and unexpected changes

Why Should You Invest in OptiProERP’s Advanced Planning & Scheduling?

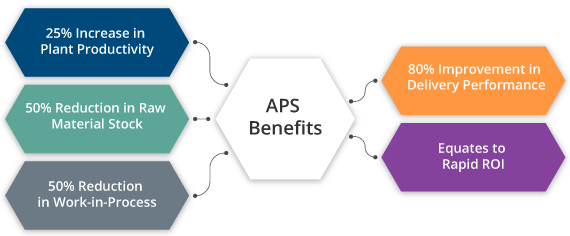

Gain an Immediate Return on Investment

Savings and efficiencies generated by OptiProERP’s APS allow you to recover your investment in a matter of months in most cases

Improve Planning and Scheduling Accuracy

Schedule quickly and accurately to minimize downtime and increase efficiency

Boost Productivity

25% improvement in plant productivity by minimizing setup, balancing loads, pegging of components and material, and optimizing your production plan

Reduce Inventory and Man-Hour Costs

Up to 50% reduction in raw material and WIP stock by optimizing and synchronizing inventory purchases with your production plan

Improve Overall Equipment Effectiveness and Reduce Machine Downtime

Take all resources, including machines, into account to improve equipment usage and minimize resource downtime

Increase Visibility

Fast scheduling with an interactive and graphical planning board, for visibility across the organization

Improve On-time Deliveries and Customer Service

80% improvement in on-time deliveries with accurate scheduling for greater customer satisfaction

Make Better Tactical and Strategic Decisions

Use decision tools for better short-term tactical planning with a few weeks planning horizon and detailed sequencing and scheduling, and long-term strategic planning covering months and years

OptiProERP’s Advanced Planning & Scheduling

Brings Industry 4.0 Capabilities to Small and Midsize Manufacturers

For manufacturers small and large, digitalization is changing everything. Manufacturers of all sizes are needing to react more quickly and intelligently to unforeseen changes, such as supply change disruptions, changes in lead times, and ever-changing customer demands.

OptiProERP’s Advanced Planning and Scheduling is specifically designed to meet this need for small and midsize manufacturers with entry-level Industry 4.0 capabilities:

- Simulates your environment by considering your resource capacity

- Analyzes ‘what if’ scenarios to create an optimized production plan

- Uses advanced algorithms to balance demand and capacity

- Schedules orders quickly using intelligent built-in rules

- Simplifies planning and scheduling with interactive and visual tools

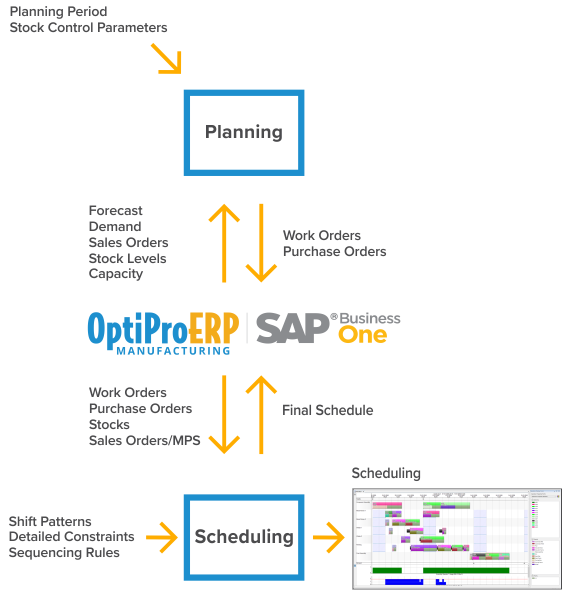

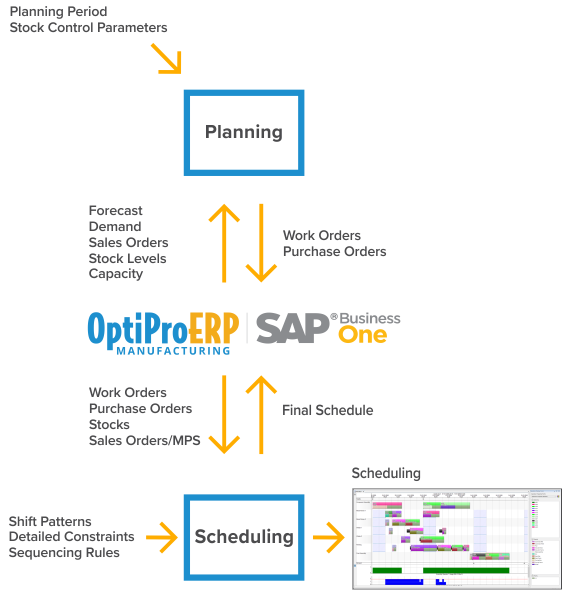

How OptiProERP’s Advanced Planning & Scheduling Works for You

Model Your Manufacturing Environment

On the demand side, the solution considers forecasts, long-term orders, and overall demand planning. On the capacity side, it takes into account the availability of resources (machines, labor, tooling, materials, and more) and additional constraints to ensure an accurate model of your environment.

Plan in Various Time Horizons with Finite or Infinite Capacity

Planning can be executed in finite or infinite capacity mode and planning time periods can be days, weeks, months, or a combination of all three. Detailed production schedule information can be sent back to the production plan.

Schedule Digitally with Multiple or No Constraints and Defined Objectives

Simply click and drag, and the production of a particular item can be moved from one planning period to another. Manually interact with the schedule to make changes, save, and digitally push updates to your whole production schedule. Define schedule optimization rules to deal with problems such as minimizing changeover times and preferred sequencing.

Generate the Best Achievable Production Schedule for Your Needs

Taking your business objectives, forecasts, demand, and capacity constraints into account, the solution determines what and how much to make, where and when to make it, and exactly what materials and resources are required to achieve your optimized and achievable production schedule.

Support Tactical and Strategic Decision-Making

The solution is designed to support decision making about the feasibility and affects to your production as well as major production capacity decisions. It also provides decision-making support for overtime, order prioritization, split production batches, due date negotiation, and order processing.

Model Your Manufacturing Environment

On the demand side, the solution considers forecasts, long-term orders, and overall demand planning. On the capacity side, it takes into account the availability of resources (machines, labor, tooling, materials, and more) and additional constraints to ensure an accurate model of your environment.

Plan in Various Time Horizons with Finite or Infinite Capacity

Planning can be executed in finite or infinite capacity mode and planning time periods can be days, weeks, months, or a combination of all three. Detailed production schedule information can be sent back to the production plan.

Schedule Digitally with Multiple or No Constraints and Defined Objectives

Simply click and drag, and the production of a particular item can be moved from one planning period to another. Manually interact with the schedule to make changes, save, and digitally push updates to your whole production schedule. Define schedule optimization rules to deal with problems such as minimizing changeover times and preferred sequencing.

Generate the Best Achievable Production Schedule for Your Needs

Taking your business objectives, forecasts, demand, and capacity constraints into account, the solution determines what and how much to make, where and when to make it, and exactly what materials and resources are required to achieve your optimized and achievable production schedule.

Support Tactical and Strategic Decision-Making

The solution is designed to support decision making about the feasibility and affects to your production as well as major production capacity decisions. It also provides decision-making support for overtime, order prioritization, split production batches, due date negotiation, and order processing.

OptiProERP’s Advanced Planning & Scheduling Functionality

Master Production Scheduling (MPS)

Work with projected and actual supply chain demand to create production, purchasing, and inventory schedules.

Finite and Rough Cut Capacity Planning

Define total operational capacity based on machines, materials, tooling, and resources available.

Material Requirements Planning (MRP)

Automate purchasing and production to ensure inventory levels are optimized and available when needed.

Demand Forecasting

Forecast inventory demand by sales order, historical sales patterns or to meet minimum stock requirements.

Operational Capacity

Working backwards, planning engine automatically calculates materials, resources, and capacity needed to complete each step.

Global Planning

Planning engine identifies demand for multi-plant entities, consolidating orders for more efficient procurement.

BOM Level Planning

Explode the planning Bill of Materials (BOM) and calculate the production plan for lower-level items in the same way.

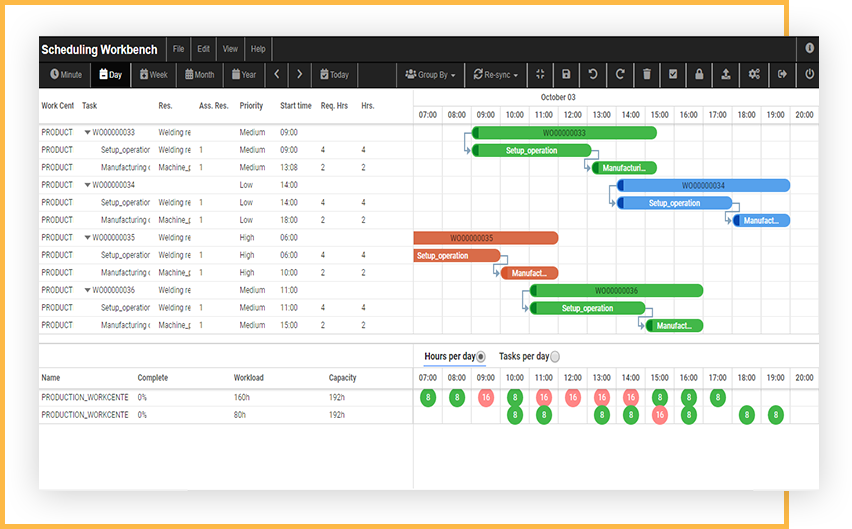

Interactive Scheduling / Scheduling Workbench

Visualize and interact with your production schedule. Click and drag to move production orders and update production schedules automatically.

‘What if’ Simulations

Simulate and evaluate multiple ‘what if’ scenarios, impact analysis, and capable-to-promise to support your daily activities.

Make-to-Order Planning

Quickly assess the affects of future demand changes and if it’s possible to meet new requirements when a change in demand, quantity, or delivery date occurs.

Make-to-Stock Planning

Generate an accurate and achievable schedule considering rough cut capacity, target days of stock cover, min and max re-order quantities, and more.

Advanced Constraint Modeling

Model various resource constraints including primary, secondary, materials, resources, tooling, labor, and machines.

Advanced Material Handling

Implement custom rules about how materials are consumed to ensure sub-assemblies and raw materials are used according to business rules.

Advanced Schedule Optimization

Define schedule optimization rules to deal with problems such as minimizing changeover times, WIP, and stock levels.

Order Based Multi-Constraint Scheduling

Create order-based schedules and apply a ranking or weighting to prioritize orders based on resources available and additional constraints.

Comprehensive Traceability

Trace and manage changes, costs, delays, and more.

Flexible and Customizable

Configure your planning and scheduling engine to your needs with one of the most customizable solutions on the market.

Preconfigured Reports and Alerts

Run quickly and intelligently with best practice reports and alerts already configured out-of-the-box.

Forecast Consumption

Choose a to consume or not consume forecast, and you may choose to consume forward, backward, first forward and then backward, and finally backward and then forward.

Rescheduling

This function will suggest you push out or cancel unutilized production orders/purchase orders.

Pegging

Pegs current supplies to current demands respecting applicable rescheduling rules (Pegging Window) and derives the balance demands that need to be fulfilled.

Supply Manipulation Rules

The APS engine generates supply recommendations after performing demand shortfall aggregation based on quantity manipulation rules (Minimum Order Quantity, Order Multiplier, Default lot size on routing) defined at the item level.

Dashboard

The dashboard allows you to view the last plan run output, exceptions, view pegging information, view RCCP, and view and release recommendations.

Benefits of OptiProERP’s Advanced Planning and Scheduling Software

OptiProERP’s Advanced Planning & Scheduling Data Sheet

Learn more about how OptiProERP’s Advanced Planning & Scheduling software helps you digitally orchestrate your manufacturing processes to keep production flowing as smoothly as possible.

OptiProERP’s Advanced Planning & Scheduling Data Sheet

Learn more about how OptiProERP’s Advanced Planning & Scheduling software helps you digitally orchestrate your manufacturing processes to keep production flowing as smoothly as possible.

A Roadmap for ERP Selection in Today’s Digital World

Download our free advisory guide with the six things you should consider on your journey to selecting a new ERP solution in today’s digital world.

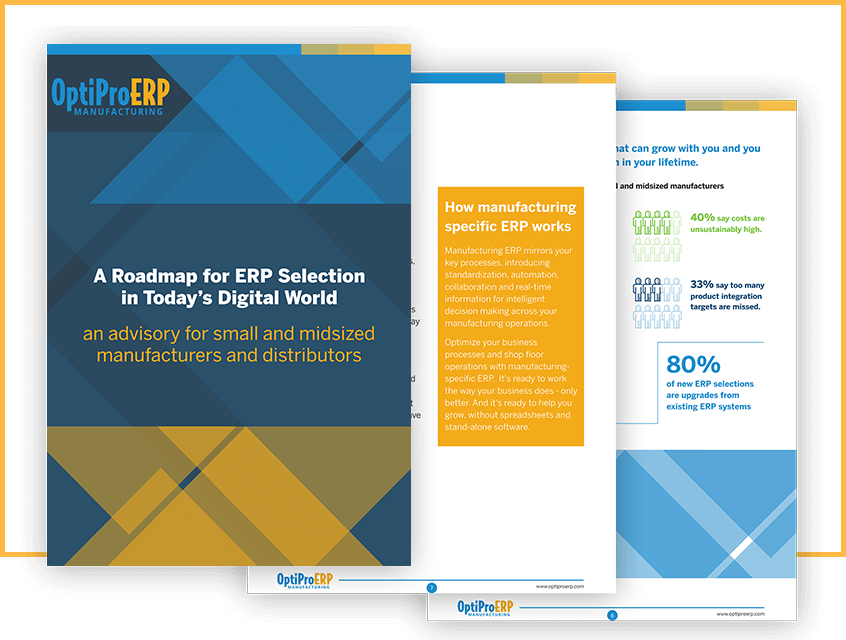

How to Know if You Need Advanced Planning & Scheduling Software

If questions like these are keeping you awake at night, you will likely benefit from OptiProERP’s Advanced Planning & Scheduling software

See how OptiProERP meets your unique manufacturing needs