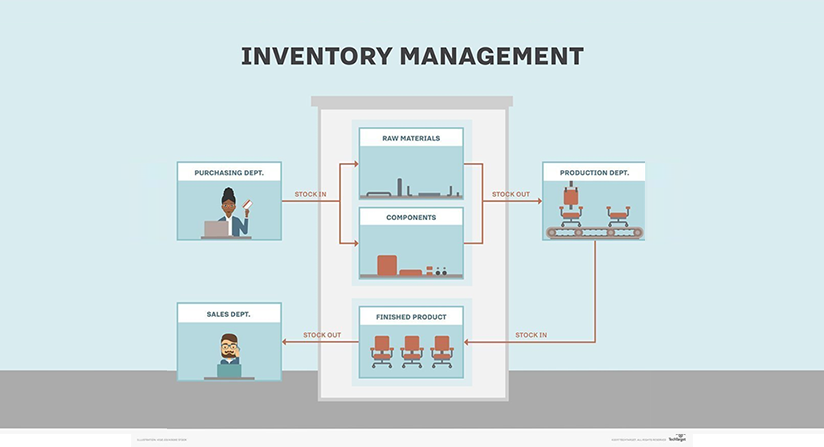

Manufacturing is complex. There are many tasks involved in the manufacturing process, from maintaining accurate stock levels to controlling production functions. Manufacturers used to manually plan production and manage purchasing activities. That was before computers dominated the industry. But today there are software solutions available to help handle these complex tasks.

What is Material Requirements Planning?

General Electric and Rolls Royce developed the first computerized Material Requirements Planning (MRP) system in the early 1950s. The program was released in the 1960s for other manufacturers to use.

The first generation of MRP systems, or MRP I, was designed to recognize the relationships between raw materials, parts, assemblies, and products. These make up the bill of materials (BOM) that is the foundation of MRP. MRP focuses on determining the materials required in the production process. It helps you get answers to questions such as: What items are necessary for production? When are they required? How many are needed?

What is the functionality of MRP?

The main functionality of MRP is:

- To maintain the minimum required stock

- To ensure raw materials are available for production

- To ensure finished goods are ready for on-time delivery

- To plan manufacturing activities, delivery schedules, and purchasing activities

What are the benefits of MRP?

1. Optimized Inventory

MRP ensures that materials are available when needed for the production process. It automates processes to end error-prone manual entries. And, it lets the production area know when it is time for product deliveries.

2. Lower Costs

With MRP, inventory is kept at optimal levels. It eliminates the need to place last-minute, emergency supply orders, along with the need to keep excess stock on hand. MRP helps keep costs down and improves revenue.

3. Increased Productivity

With the required materials always available, production is efficient. There is less employee downtime and job throughput improves.

Evolution to MRP II

Greater competition and consumer demand for customized products developed. Manufacturers had to become more strategic about acquiring raw materials. The opening up of a global marketplace meant many items came from more distant locations. This brought more complexity to the supply chain.

MRP II was developed in the 1980s to help manufacturers forecast their material needs and plan for capacity. MRP II includes all of the functionality in MRP I, but also includes general accounting, quality management, demand estimations, and machine capacity scheduling.

What is the functionality of MRP II?

- Material requirements planning

- Bill of Materials (BOM)

- Inventory management

- Capacity planning

- Master Production Schedule (MPS)

- Purchasing management

- Customer order management

- Forecasting and demand management

- Cost accounting

- General accounting

MRP II enables better supply chain visibility and enhances your relationships with suppliers. It improves a company’s bottom line through advanced planning, scheduling, and forecasting capabilities. It is more advanced than MRP I and extends to other areas of the company. MRP II helps manufacturers be more strategic.

Can you still purchase MRP I?

MRP I is no longer sold and MRP II has replaced it. Some smaller manufacturers are still using MRP I or homegrown software with its functionality.

The added functionality in MRP II is very beneficial to manufacturers. Today’s growing manufacturers are looking for help to forecast resources for production.

What are the benefits of MRP II?

MRP II has the benefits of MRP I listed above, as well as:

1. Purchase Planning

Manufacturers can track the production process and know in advance when materials will be needed. Procurement managers can better plan for purchases. They can identify the best items to buy, the best suppliers to get them from, and the best time to order. The system can help procurement look at shipping, storage, and carrying costs. This knowledge allows procurement to get the most cost-effective choice for on-time production. With automated orders, the system purchases supplies as needed.

2. Forecasting Demand

MRP II allows manufacturers to create a detailed production schedule. It determines the needs of both machines and labor as materials arrive. It shows production costs based on machine time, labor, and materials used. That information transfers to the finance department.

Information from customer orders helps to forecast demand for materials. Having this data helps you strategize for the months ahead.

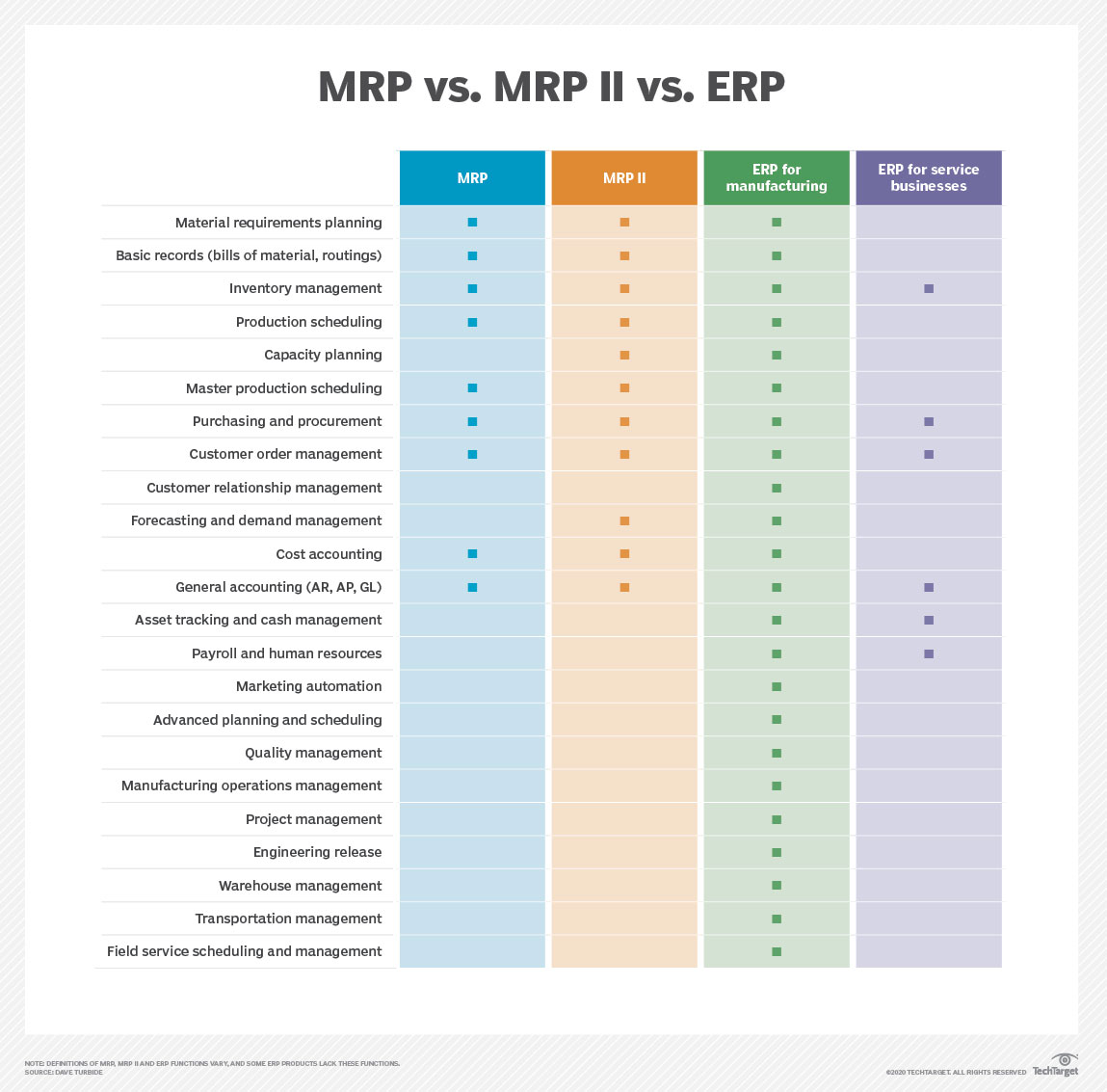

Below is a chart that shows the difference between MRP, MRP II, and ERP which we will get into next.

What is the difference between MRP and ERP?

ERP is different from MRP and MRP II because it offers:

- Real-time visibility, insights, and collaboration

- Automation of manual processes across the organization

- A single and consolidated database

- A common user interface

- Modules that manage critical functions of an organization

- Integration across functions, departments, and data

ERP has everything you need in a single system. This eliminates IT hassles and ensures a streamlined workflow.

What is ERP?

MRP II has some great functionality. It is still missing many critical functions that are very beneficial to manufacturers. ERP is an extended version of MRP II to include all core business functions and processes. It manages production and inventory, finances and accounting, sales, CRM, HR, and more.

ERP is an integrated suite of business management tools that provides a real-time view of every department. All activity is visible in a single database within the ERP system. That allows everyone to work from the same information.

What is the functionality of ERP?

- Finance and accounting

- Human capital management

- Procurement

- Manufacturing

- Order management

- Inventory management

- Warehouse management

- Supply chain management

- Customer relationship management

- E-commerce

What are the benefits of ERP?

1. Improved productivity

ERP streamlines processes across the company. It automates your workflow and minimizes errors. ERP improves communication and collaboration between employees. It streamlines operational processes through innovation and best practices. There is no redundancy because the information is only entered once. And information is immediate and accurate for better decision-making.

2. Saves time and money

ERP helps organizations lower costs by keeping their inventory at optimal levels. Month-end closings are faster. Streamlined processes provide greater efficiency. It provides insight into all aspects of the business to identify areas to cut costs. Orders are faster and shipped on time. Increased capacity helps to increase production. ERP optimizes your workflow and keeps costs low.

3. Easy forecasting and reporting

ERP forecasts and reports for all parts of a business. Manufacturers can understand what factors are responsible for increased sales. It identifies optimal inventory levels to meet future demand. It helps procurement managers buy needed items in the most cost-effective manner possible. Intelligent reporting helps to manage complex data. Powerful business intelligence tools give management an accurate view of the entire organization.

4. Greater collaboration

ERP has a centralized database so everyone sees the same information. Because departments are connected it allows for greater communication and collaboration. ERP integration eliminates redundancy and provides everyone with consistent and accurate data. By having everything connected, there are no data silos. ERP provides employees with greater productivity and efficiency.

5. Enhanced data security

ERP systems have excellent data security. Managers and supervisors can enhance data restrictions with user-permission settings. Data inserted into a modern ERP system is secure and coded. Vendors provide ERP updates timely to remove the risk of data theft.

6. Mobility and flexibility

ERP users can access business data from their mobile devices. Mobile-friendly ERP allows employees to be on the move. Sales and service teams can work in the field. Employees can get answers from supervisors who are out of the office. Purchase requests get approved in seconds. Mobile alerts can notify of items needing attention.

7. Better decision making

ERP provides KPIs and forecasts on easy-to-read dashboards. Real-time data provides insights into purchasing, production, inventory movement, and warehouse management. Accurate and up-to-date data also helps you generate greater sales revenue while also identifying deficits. Drilled-down data provides a more granular view to better analyze situations to make smarter business decisions.

8. Achieve compliance

ERP systems keep on top of regulatory compliance. They enforce industry-specific requirements and track, verify, and audit transactions. Material tracking lets manufacturers notify the supplier if there are any quality issues. These safety measures ensure industry rules aren’t violated and financial penalties aren’t incurred.

The global ERP software market is expected to reach $93.34 billion by the year 2028. The features of MRP and MRP II are included in ERP. This is why businesses are adopting ERP solutions instead of disparate standalone tools.

White Paper: A Roadmap for ERP Selection in Today’s Digital World

What is industry-specific ERP?

An industry-specific ERP is different from a generic ERP. Generic ERP handles basic business operations. Industry-specific ERP has functionality for a certain type of business. It also handles general business operations. For example, manufacturing ERP has modules that include Production Management, Warehouse Management, Quality Management, Supply Chain Management, Material Requirement Planning, and Shop Floor Execution. These modules work together to provide an end-to-end solution.

Summary

Manufacturers need to be able to keep their supply chain optimized. Efficient resource management ensures low inventory costs and on-time deliveries. Not having control over resources can hurt a business’s reputation.

MRP, MRP II, and ERP streamline manufacturing and business operations in an organization. Technology, globalization, and complexity have brought about new functionality. Manufacturing software has evolved from MRP to MRP II to ERP.

ERP can reduce costs, increase profitability, improve internal collaboration, and increase customer satisfaction. It helps businesses manage critical functions. To learn more about OptiProERP’s manufacturing ERP, please reach us here.

Follow Us