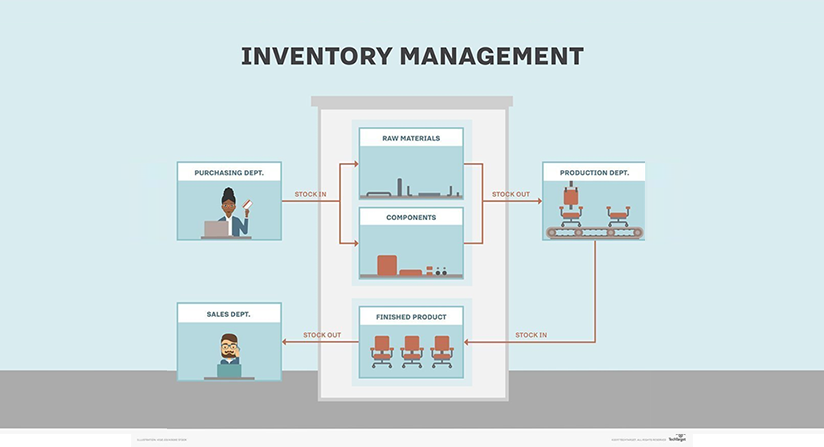

A warehouse is the cornerstone of every manufacturing organization. It is simply a central location where goods are procured, stored, and distributed for further processing.

From handling major and minor warehouse operations such as inspection, procurement, acceptance, put-away, picking, packing, order assembly, and shipping, a warehouse management system (WMS) helps in directing or validating every step by recording and capturing inventory movement.

A warehouse management system (WMS) remains a prerequisite of supply chain management that seamlessly manages the unique customer demand requirements of distribution channels.

With a WMS, warehouse staff members can easily keep up with the day-to-day operations and work efficiently to achieve targets.

- A WMS can improve labor productivity by offering real-time inventory visibility, increase warehouse accuracy, and reduce the level of inventory risks.

- It eliminates the need for paperwork and manual processes; a WMS facilitates automation of warehouse operations and this reduces the time and effort of staff.

It lets you generate multi-dimensional barcodes, scan QR codes, print labels, view a list of purchase orders and real-time inventory consumption, facilitate inter-company warehouse transfers & provide authorization to staff members (regarding accessibility).

- Seamless Integration With ERP Platforms

When data in a WMS is integrated with your ERP, it expedites the process and facilitates accuracy and real-time tracking of data across the organization. It ensures that all of the information is stored on a single platform and is synchronized well with the other departments.

For example, if the sales team is not well acquainted with a warehouse management system, they cannot effectively update their customers regarding the order. To make sure staff members and other departments are not kept out of the loop or have an unclear picture of the supply chain, a WMS should be integrated with an ERP platform such as SAP Business One.

- Mobile Deployment – Anytime, Anywhere Access

In this tech-driven world, employees travel overseas, have flexible working hours, and need instant access to such things as warehouse, meeting, and conference data. An ideal warehouse management system features a mobile-friendly interface so it can be accessed from handheld devices. It allows management professionals to set authorities, view purchase orders, raw materials, finished goods, and track inventory on the go.

By updating the data instantly on a web-enabled or a mobile-friendly WMS, it automatically is updated in the ERP system. This facilitates clarity between the departments and offers real-time inventory consumption and visibility to the necessary staff members. Field workers can electronically generate reports, record every transaction, and manage the daily tasks at their fingertips.

- Cost-reduction Through Resource Optimization

Are you able to determine what inventory has been procured in the warehouse, at what date, and know what it is being used for? Do you find it difficult to track and view the resources (man, material, and time) on the go? If yes, then it can be one of the huge hindrances in business productivity and can lead to human errors and procrastination of tasks.

With OptiProERP, everything gets done on time, by the right person! It’s a full-fledged and powerful mobile-friendly solution that allows you to plan and balance the number of orders, monitor the outbound progress, streamline picking-packing and dispatching, and help warehouse managers define labor standards so that everyday operations are done on time and with utmost accuracy.

A WMS eliminates unneeded put-away and helps warehouse staff to manage distribution, procurement, and other tasks electronically. Employees can capture, record, and view the list of data anytime, anywhere.

- Inbound and Outbound Flow of Inventory

Needless to say that picking and dispatching items are tedious and puzzling tasks that require proper planning and direction. Goods receipt concerning a purchase order, production order, delivery, or other goods receipt states the status of the warehouse. The business must maintain a record and a list of goods received so that it can allow the necessary departments to process them.

OptiProERP WMS allows you to –

- Scan and print the barcode that is placed or has to place on the item

- Print labels and generate the item numbers (auto batch/serial number)

- Define details of the batch, serial, and non-tracked goods using the Item Master-Detail screen

The scenario of inbound and outbound movements (goods receipt) has changed in the past few years. Every transaction is captured electronically and processes are automated and driven by state-of-the-art software systems. WMS by OptiProERP is exclusively designed for managing bin operations seamlessly. Its responsive screens feature and intuitive UI can automatically adjust as per the size and orientation of the device.

- Paperless Process of Inventory Transfer (warehouse to warehouse)

Paper-based transactions are unnecessarily cumbersome and wasteful. The OptiProERP WMS solution eliminates paper form processing by offering easily accessible features that make warehouse transfers a less time-consuming task.

For instance, if Warehouse A requires a huge variety of products from Warehouse B, they can exchange goods by using the warehouse transfer option. You can mention the item code, batch number, bin code, on hand and transfer quantity, and process it in a few minutes. After the items are transferred, you’ll receive a confirmation message with their reference number and transaction details. Every detail is mentioned in the web-enabled and mobile-friendly application and thus, it saves time, effort and promotes real-time tracking of goods.

Final Thoughts –

A warehouse management system is a web-based and mobile-friendly application that ensures data accuracy, improves business decision making, and simplifies and standardizes everyday warehouse operations by offering exhaustive functions. From setting and generating barcodes, to printing and recording goods receipt POs, warehouse transfers, bin transfers, and item label printing, it facilitates an array of functions that add more to your business productivity by reducing labor costs and time.

If you wish to learn more about the functions of a WMS and how can you leverage it, please contact us.

Follow Us