Once you have selected ERP software for your organization, the next step is ERP implementation. Implementing ERP software is quite a complex and time-consuming process; however, if done diligently with a designed implementation plan and clear steps, you can maximize its success while saving time and money.

What is ERP implementation?

ERP implementation is the process of planning, installing, and configuring ERP software within an organization. The primary objective of implementing ERP software is to improve efficiency and productivity and provide real-time visibility into all departments.

Here are some ERP implementation mistakes small and mid-size manufacturers should avoid:

1. Selecting the wrong ERP software

The selection of an ERP system is quite a tedious, time-consuming, and mind-boggling process that requires you to evaluate multiple options to find one that will achieve your business objectives.

If you evaluate the ERP solutions and take the time to analyze how they can help you meet your goals, it will remove customization costs and reduce implementation time.

2. Poor planning

Creating a roadmap early on is always advisable. It should be ensured that no steps are missed in order to achieve a successful implementation.

Identifying the objectives behind an ERP implementation and which areas it will need to improve is essential. Undefined goals and lack of attention lead to unnecessary overhead costs.

3. Reluctance to adapt

Employees working in any organization become resistant to change. They are accustomed to the current way of doing things. It’s crucial for users to be comfortable with the new ERP system by providing them with training regarding why it is needed, how it will be beneficial, and how to use it correctly.

ERP will increase business productivity by unifying data in one system and making it accessible across every department, irrespective of location. Your employees should understand this and be interested in learning how to use it. Strong leadership in the implementation can help build employee excitement around the ERP system to increase the success of the implementation.

4. SMEs fail to focus on the future progression of business

What is the reason for getting the software implemented? Of course, you foresee business growth and want to improve productivity and your bottom line. However, every small and mid-sized business should clearly define its operational processes and understand its business needs. It helps to define specific goals and share them with vendors to ensure you get what you need.

For example, you should know the pros and cons of on-cloud vs. on-premise deployment. If you choose a cloud system, understand its prerequisites, such as proper internet connectivity, subscription-based payments, remote implementation, and more.

For on-premise deployment, you should understand the upfront fees, dedicated IT personnel needed, and the fact that you’ll need up-to-date servers. Take time to evaluate your needs and select the best deployment type that fits your unique business requirements.

5. Knowledge transfer and training

Sometimes ERP implementations fail to deliver positive results. Reasons may be the software is a bad match or leadership is not behind the change. One of the most critical aspects of an ERP implementation to ensure success is good training. Its essential staff understand how to use the software effectively.

Some other things that could derail your project are:

- Not budgeting sufficient time & money if you are taking a big leap in technology.

- Treating compliance as an afterthought – make it integral to the project.

- If you are moving to the cloud, over-estimating staff savings.

- Also in the cloud: too much customization – cloud environments are designed to be used in a standardized way.

- Not having an ongoing maintenance plan to keep the system moving ahead after implementation.

What are ERP implementation best practices?

Assign a core project team

Your ERP project team is the most significant factor in your implementation. A capable and efficient team will ensure your ERP software works as it should. These people need ample time, support, and skills to ensure an effective ERP implementation. Without a good project team, your company risks delays and growing costs, and the software may not get configured to meet your needs.

An ERP implementation team should include the following:

- A project sponsor

- A project manager

- Representatives of critical business units

The implementation team should:

- Establish goals, requirements, and key performance indicators (KPIs)

- Carry out the daily project management tasks

Define clear requirements

Precise requirements that link to business goals are vital to an ERP implementation. Those goals may include streamlining processes to save time and lower costs. Other objectives could be to respond to customers better and improve analysis across the business.

Analyzing current systems, workflows, and critical business processes are aspects of requirements gathering. It’s essential to gather data on what optimization is needed to improve component business processes such as accounting, customer relationship management (CRM), human resources, and inventory to achieve your organization’s business goals. The implementation team needs to understand workflow to realize how the ERP solution can provide improvement.

Establish KPIs

Once the project team understands the company’s essential requirements, they can identify specific KPIs. These represent metrics to measure the success of the ERP implementation. For instance, manufacturers may want to improve costs, cycle time, demand forecast accuracy, downtimes, and inventory turns. However, a retailer might opt to work on average purchase value, customer conversion rates, inventory turnover, profit margins, sales per square foot, sell-through rates, and total sales. Defining measurable end goals and benefits will help keep your team focused on the big picture.

Ensure a solid project management framework

Implementation of ERP can take anywhere from a couple of weeks for a system that is used “out of the box” and designed for a small to mid-sized business with little to no customization and up to one to three years for a very complex system used in a large organization. Unfortunately, ERP implementation projects are prone to scope creep due to a lack of solid project management. It’s critical to have a good project management framework to help guide your ERP implementation to successful completion.

Foster good collaboration and communication

Stakeholders must recognize the goals and objectives of your ERP implementation. Everyone in the company should understand why the ERP system benefits both them and the business.

Clear communication and collaboration will foster a mutual understanding. High-level executives such as the CEO should help communicate the project’s importance. Charts, blog posts, emails, graphs, memos, and presentations can help the CEO clarify the reasons for the ERP implementation. Regular meetings and calls can also assist in coordinating efforts, identifying problems, and communicating successes.

Migrate your data

Migrations can lead to a loss or corruption of data, especially if you’re consolidating data from various applications. That’s why it deserves plenty of planning and preparation.

Go through your data with your vendor partner early on in the process so they can see how it looks and determine the data quality. Be sure to show your vendor the critical reports you produce to inform them how the data should be set up in the system to produce the necessary analytics.

Train your users

Your employees need time to be comfortable with the new ERP system. Training makes this possible. There should be a room designated for training, and the core project team should be responsible for learning the system and helping get others trained.

Subject matter experts should be given specialized training regarding the ERP software to teach other team members and be the go-to people for queries after the Go-live process.

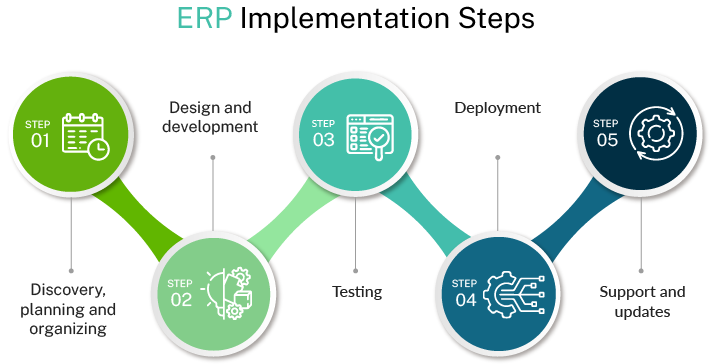

What are the steps of ERP implementation?

Discovery, planning, and organizing

Manufacturers should assess their current systems and identify the areas needing improvement. A thorough review should be made to identify gaps in business operations. This helps manufacturers make informed decisions about the functionality and features needed in the ERP software.

The first step towards a successful ERP implementation is selecting ERP after researching and evaluating multiple options. Considering the pace at which technology moves, manufacturers must invest in modern, innovative, and intelligent ERP for increased flexibility and scalability.

ERP implementation also depends on whether ERP runs on the cloud or on-premises. Cloud-based ERP software is faster to implement and does not require a huge IT team.

Design and development

The next stage is designing new workflows and business processes. A gap analysis is used to identify any areas that are not meeting business requirements. The project team should identify gaps to help create new processes and workflows. Once the ERP plan is designed properly, the next step is development.

It includes integrating ERP with the company’s current business management software (if needed) and configuring it to fit the redesigned business processes. The development stage also includes training materials to help users learn the software.

Testing

Once the business requirements are analyzed and the business process is redesigned, the next step is testing the system across all departments and ensuring it runs smoothly for all users. The testing plan involves measuring user acceptance and determining the use of ERP in the organization as per their requirements. The project team should test the critical modules the company requires and make adjustments as needed. They can also test one ERP functionality while theother modules are still in the development stage.

Deployment

This is the day you have been waiting for. The day when your ERP software goes live! However, it may come with issues that need to be fixed. The project team should be prepared to troubleshoot such issues. Data migration is an ongoing process that takes place before and after deployment.

Support and updates

The project team listens to the users’ feedback and adjusts the system if needed. Some additional functionality and configuration may be required even after the ERP implementation process. Periodic software updates are done automatically in the cloud ERP software. On-premise ERP will need to be handled by your IT staff with assistance from the vendor if needed.

Conclusion

ERP implementation is a time-consuming process that needs much pre-planning, including assessing the organization’s needs, planning a budget, selecting suitable software, and more. Once the ERP is implemented and goes live, it should increase efficiency and productivity and help to improve customer and employee satisfaction.

Whether you have a small, mid-size, or large company, ERP eliminates manual reconciliation processes, provides data transparency, streamlines operations, and improves decision-making. Please feel free to contact us to learn more about ERP benefits and the implementation process.

Follow Us