In this modern world, every manufacturer is looking for ways to reduce costs and optimize business operations to the fullest. When we talk about the manufacturing industry, production and resource optimization are crucial to an organization’s profit.

MRP or Material Requirement Planning software was developed in the 1960s to help businesses streamline and address the fluctuations in demand and supply. It was embedded with features to ensure a favorable production plan for multi-level processes.

However, MRP software that was once considered a breakthrough has now become quite outdated. Businesses prefer to invest in a comprehensive Enterprise Resource Planning (ERP) software that comprises basic business modules – production (MRP and MPS), sales, purchasing, inventory, administration, finance, accounting, and more. In the age when manufacturing industries are facing global competition, full-fledged ERP software is the key to efficient business operations. It includes top-notch planning features that make the entire process simple and stress-free.

Why is material requirement planning required in manufacturing?

Planning is paramount in any business. If you don’t have a proper roadmap, execution becomes unmanageable. For all manufacturers, the aim is to manage, plan and schedule the production process to avoid excess inventory or stock-out. Excess inventory blocks your capital, it takes up your floor, increases storage costs, and encourages waste. On the other hand, stock-outs may lead to unfulfilled orders and unsatisfied customers.

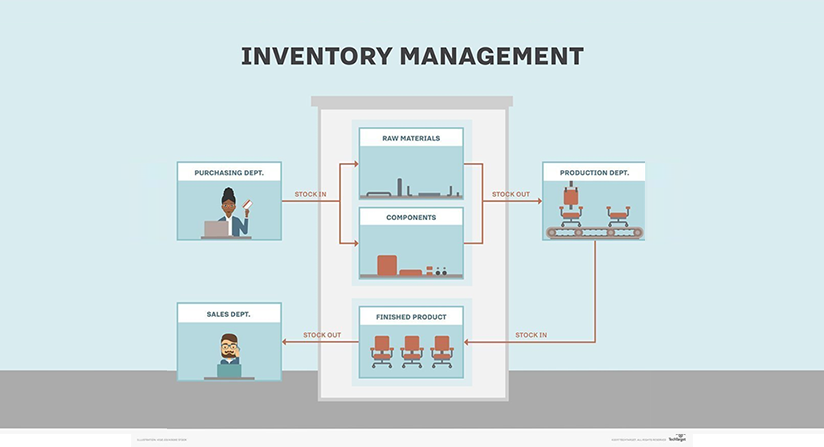

The primary purpose of material requirement planning is to ensure the accurate availability of components for production. It determines the number of finished goods to be produced and by what date they will be shipped to customers. The number of end-products planned will depend on the materials procured.

How does material requirement planning work?

Material requirement planning is a crucial part of the industries where multiple parts are used to create finished goods. Replenishment depends on future demand information. Floor managers and warehouse managers are always updated about which set of goods has to be procured or shipped.

MRP manages the entire manufacturing system while handling production planning, warehouse, and scheduling. It assists production managers and warehouse managers to plan for capacity and allocate production time. It ensures well-timed availability of components at all levels.

MRP allows manufacturers to future-proof their business by planning for anticipated demand in advance to ensure the materials needed for production are available in inventory. MRP suggests which materials should be purchased and what batches should be produced to meet demand.

How can material requirement planning add more to business value?

Material requirement planning is responsible for balancing production demand and supply. It handles both purchasing and production supply scheduling to ensure correct batch sizes and minimum stock balance. Its functionality includes:

- Global plans that simulate supply scenarios and reduce planning cycle time

- Comparing production time with lead time to ensure easy availability

- Improving shop floor performance and optimizing every resource

- Ensuring that finished goods are delivered to the customer on time

- Increasing productivity and optimizing resources

ERP software is embedded with an inbuilt material requirement planning tool that offers production planning, scheduling, and inventory control functionality across multiple organizations. Instead of choosing different tools for supply chain planning, production, material requirement planning, sales, accounting, finance, inventory, quality control, etc., it is always wiser to invest in a single quality solution that addresses every fundamental need of a manufacturing company.

OptiProERP, a trusted manufacturing ERP solution is an all-inclusive software that manages critical levels of the business while ensuring streamlined work culture. It enhances employee efficiency, reduces lead time, and expedites profitability. Here are a few ways OptiProERP with SAP Business One manages businesses efficiently:

- Accelerates product introductions and delivers more intelligent order fulfillment

- Plans finished goods, manages lead time, and eliminates last-minute scheduling

- Provides a mobile-friendly warehouse management system

- Tracks resource utilization while managing orders

Conclusion

The need for material requirement planning in manufacturing is essential as it is loaded with sophisticated planning capabilities. Irrespective of the location of the warehouse, shop floor, and packaging area, manufacturers can manage, view, and streamline core activities that are responsible for production. Three principle functions of MRP software are:

- To ensure availability of materials

- To drive down waste and promote lean manufacturing

- To automate the planning and scheduling process

Today manufacturing organizations, whether small or large, are using nimble Enterprise Resource Planning software with a range of inbuilt functionalities, modules, and add-ons that can be customized per your specific requirements. OptiProERP with SAP Business One ensures real-time visibility of data, high-grade performance, a user-friendly user interface, and everything that your business requires. With years of experience, we empower our customers to achieve their milestones. For further inquiry, email us at optiproinfo@optiproerp.com.

Follow Us