Industrial Machinery and Components is a huge industry that depends on complex products and manufacturing processes to produce goods. Considering the growing global competition, every manufacturer aims to balance customers’ demand for improved responsiveness and growth. An Industrial Machinery and Components business requires advanced technology that can drive the business and manage the level of complexities.

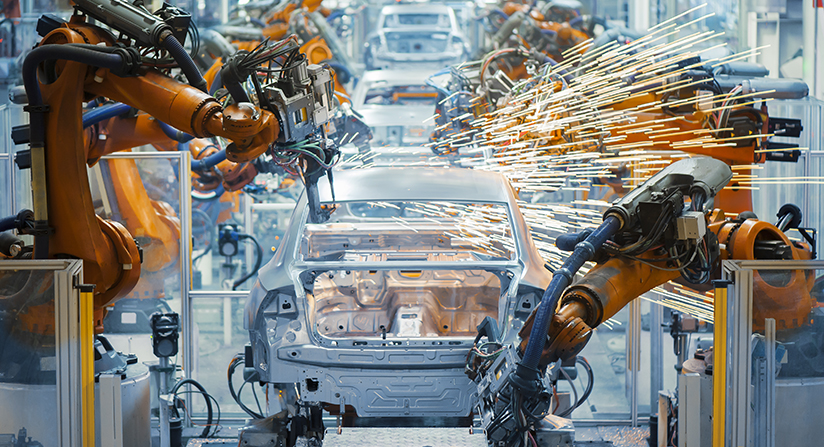

Heavy-duty machines are used in all industries – in the agricultural sector, power generation, construction, transportation, forestry, and many more. In the last couple of years, the IM&C industry has drastically evolved to automate processes using robotics for improved production.

IM&C is a capital-intensive industry with compliance regulations that have to be followed. Therefore, it is always advisable to invest in a reliable and complete ERP solution that can manage the specific operations of the organization to eliminate data redundancy, unify and secure data, and improve the production process.

IM&C in the Digital Era

Industrial Machinery and Components manufacturing has come a long way in a couple of years. To take advantage of the state-of-art technology this world is using, IM&C manufacturers should focus on innovative operational models, aggressive hiring of skilled personnel, targeted investments, and smart partnerships.

Technology provides strategic advantages to businesses of all sizes. For IM&C manufacturers, it is crucial to innovate their products and services by embracing advanced technology and connectivity. With technology evolving at warp speed, manufacturers are expected to increase their breadth of services, supply chain efficiency, and mitigate the risks of poor product quality and sluggish timelines.

The manufacturing revolution will enable faster, flexible, and more efficient processes to produce quality products in time. Moreover, new entrants are breaking the traditional manufacturing domains. Big players from all over the world are enthused by the latest technology as it will promote streamlined and smooth operations. From artificial intelligence, machine learning, cloud technology, to blockchain technology, many are used by businesses to deliver significant horsepower.

Challenges faced by IM&C manufacturers

- Ensuring product quality

Manufacturers must warrant high-quality products to avoid product recalls. Keeping abreast with regulations and maintaining product quality are crucial requirements of IM&C manufacturing. Industrial machinery organizations understand that theirs is a capital-intensive manufacturing process and therefore, seek a complete solution that can promote productivity and timely delivery of tasks.

- Innovating while reducing the cost

Lack of innovation is a stumbling block in IM&C manufacturing. Planning, production process, and machine capability should be considered as the top-most priority for businesses. One wrong step and the entire process will suffer. Stronger collaboration with engineering partners, improved visibility across departments, reduced cost, and better optimization of resources are some basic aspects that nurture a productive environment.

- Integrating business processes more closely

IM&C is a niche industry and requires complex tasks to be done on time. When there are multiple departments and teams, it becomes difficult to manage team-specific data and resources. For example, if the sales team is not able to interact with the warehouse personnel, a good sales deal may be lost.

- Global competition

With global competition, you need to create a good rapport in the marketplace. Offering high-quality products to potential customers is one way to do so. The second option that can make your business stand out is by demonstrating a deep understanding of your customers’ industry.

An ERP solution for IM&C manufacturing

An industry-specific solution that supports strong capabilities can manage the most complex as well as the smallest operation in your business. Generic ERP software is a good fit for many industries but IM&C needs more! An Enterprise Resource Planning solution is a suite of business management tools that emphasizes unifying business data and streamlining business operations.

A complete ERP solution allows businesses to meet unique needs while managing data, production, quality control, the supply chain, procurement, sales, CRM, accounts, and finance. This software helps manufacturers respond to innovation, share risks, reduce the cost of production, and meet the deadline without hassles. An ERP system controls documentation; generates sales quotations, invoices, and work orders; updates inventory status, and tracks labor transactions and planning materials.

ERP offers a wide assortment of features to meet the ever-growing challenges faced by the IM&C industry –

- You can easily perform scheduling and routing during the manufacturing process

- Sales functionality supports make-to-order and third-party processing

- ERP lets you manage sales quotations, shipments, invoices, and customer’s needs

- With inventory management functionality, scanning and printing the barcode becomes easy

- Tracking of lots and batches makes it simple for businesses to record information

- Managing test processes and maintaining quality assurance is easier

OptiProERP is a reliable manufacturing ERP solution designed by a team of experienced developers and SAP-certified professionals who are dedicated to providing best-in-class services to their valuable customers. From managing your production capabilities to streamlining quality control operations and warehouse management, OptiProERP is an ideal software to take away your day-to-day business hassles. To know more about OptiProERP, get in touch with us at info@optiproerp.com.

Follow Us