With 2024 on the horizon, more manufacturers are adopting smart manufacturing technology. It is helping them capture benefits across the entire manufacturing value chain. Key components of smart manufacturing include connected sensors and devices, data analytics and big data, AI, cloud computing, cyber security, digital twins, advanced robotics, blockchain, etc.

Smart manufacturing is helping businesses succeed in many ways to include increased production capacity, reduced material losses, enhanced employee satisfaction, and improved lead times. Examples of intelligent factories include on-demand manufacturing and virtual inventories. Through these technologies and process enhancements, manufacturers can anticipate a new scale of innovation in 2024.

The International Data Corporation predicts that 90% of manufacturing companies will use smart manufacturing technologies by 2025. In this blog, we will explore the top smart manufacturing trends shaping the industry in 2024 and how you can embrace the growing opportunities.

1. Predictive Maintenance and Digital Twin Technology

Predictive Maintenance helps predict the future potential state of equipment to determine the time of maintenance operations and their performance. It collects data from sensors and advanced analytical tools, detects and addresses issues, and predicts the future state of equipment. Predictive maintenance is expected to grow even more in 2024 and in future years.

Digital Twins are virtual representations of physical systems that transform manufacturing by providing real-time insights into performance, enabling efficient asset management, streamlining product development, and optimizing factory environments. In 2024, Digital Twins will play an increasingly crucial role in shaping a manufacturing future characterized by efficiency, flexibility, and sustainability.

AI, Machine Learning, and Advanced Analytics drive business efficiency

Generative Artificial Intelligence, Machine Learning, and Advanced Analytics help manufacturers identify and simulate potential disruptions or risks in the supply chain. It also allows supply chain managers to proactively implement mitigation strategies, develop contingency plans, and help improve overall resilience.

In 2024, AI will automate tasks, optimize production processes, and improve decision-making. This will help manufacturers remain competitive in the changing market. AI is expected to have even more benefits in the coming year.

2. Hype in automation, connectivity, and personalization

The advent of automation and connectivity has already been seen in the past years, but these areas are expected to accelerate further in 2024 and 2025. While most manufacturers have implemented higher levels of automation, small and mid-sized companies are also trying to catch up.

Robotic automation is emerging as one of the most crucial technologies in the manufacturing sector. Investing in this technology can streamline operations such as material handling, assembly, machining, finishing, and more. Modern-day automation includes smart factories and smart devices, robots with attached sensors, and robotic arms to make operations easier.

3. Adopting digital solutions to drive supply chain efficiency

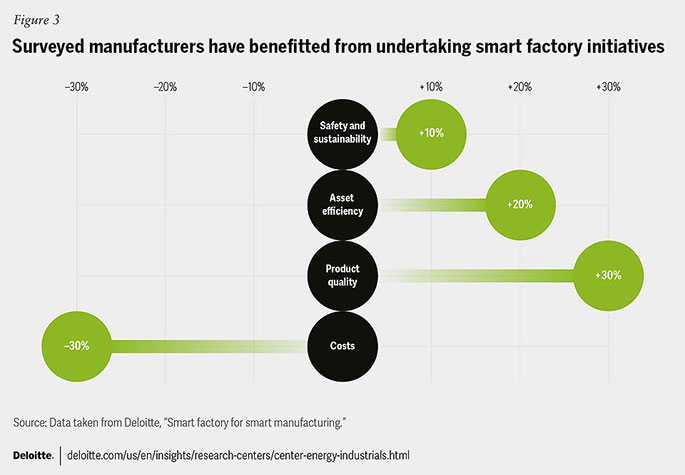

A recent Deloitte study indicated that 86% of surveyed manufacturing executives believe smart factory solutions will be the primary drivers of competitiveness in the next five years. The potential benefits of smart manufacturing include labor productivity, product quality, cost reduction, asset efficiency, and sustainability advancements.

Smart manufacturing systems provide unparalleled visibility into all aspects of the production process. Managers get access to real-time data to make informed decisions. For example, they can monitor inventory levels and anticipate production bottlenecks, leading to more efficient and responsive supply chain management.

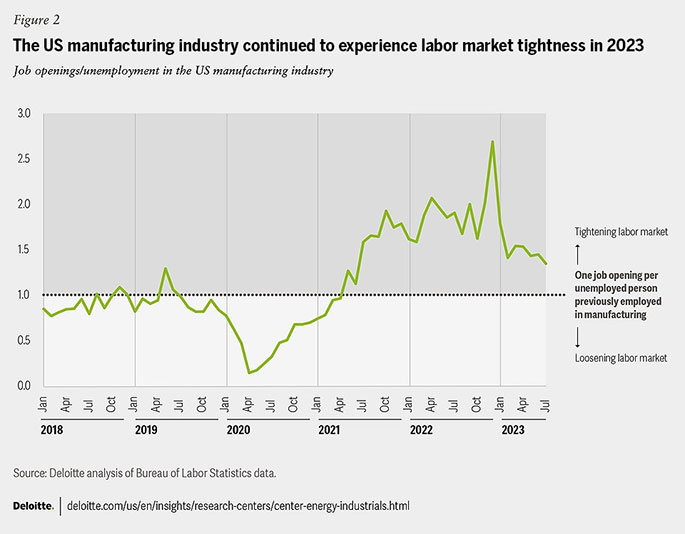

4. Enhancing workforce strategies for a better future

The increased adoption of smart manufacturing strategies and digital tools in 2024 and beyond requires advanced technical and digital skills from employees. Therefore, manufacturers should focus on reskilling and upskilling initiatives by partnering with startups to access new technology, collaborating with academic institutions, and tapping into the knowledge of retirees.

Let’s explore the statistics about smart manufacturing trends:

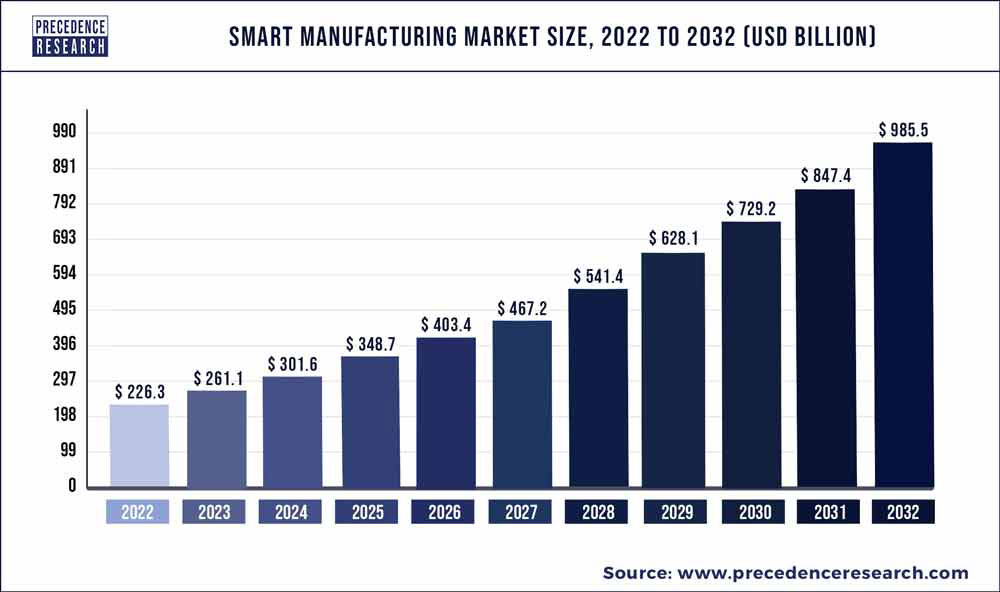

- According to Transparency Market Research (TMR), the opportunity in the global smart manufacturing market will likely reach US $548.14 Billion by 2024, expanding at a CAGR of 13.02% between 2016 and 2024.

- According to the International Federation of Robotics, the automotive industry alone represents one-third of robots installed for work in factories worldwide.

- The global smart manufacturing market is expected to grow at a CAGR of 16% from 2023 to 2032.

- Brainy Insights estimates that the smart manufacturing market will reach USD 695.07 Billion by 2032, and North America is expected to have the largest market size during this forecast period.

Conclusion

Manufacturers across the globe will continue to embrace smart manufacturing strategies and digital tools to stay competitive. Smart manufacturing technology helps manufacturers become more efficient with remote monitoring, servicing, and equipment operation. In 2024, smart manufacturing trends will continue to change the industry. Manufacturers can prepare for smart manufacturing trends by developing smart manufacturing key strategies, investing in new technologies, training employees, and partnering with other companies.

Follow Us