A Manufacturing Execution System (MES) connects with machines and workstations on the shop floor, helping to streamline production. It starts with the placement of the order through to the finished product.

What Is a Manufacturing Execution System?

What Is a Manufacturing Execution System?

A manufacturing execution system helps identify process improvements and tracks employee and machine performance. In addition, it identifies issues that are holding up production to coordinate a workaround deviation.

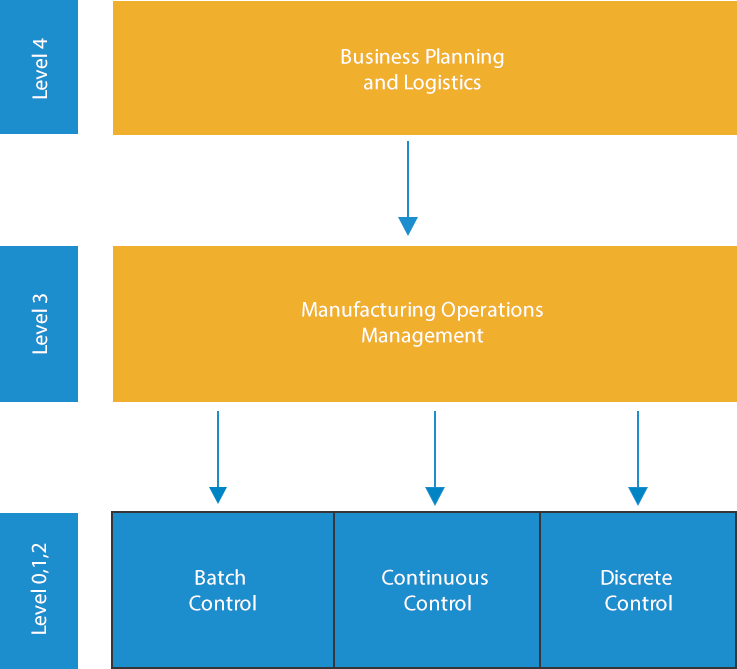

Manufacturing Execution System Architecture

Back in 1997, the Manufacturing Enterprise Solutions Association (MESA) International, which is an organization to help manufacturers effectively use IT, identified a model named the MESA-11 defining the core functions of an MES system. They are as follows:

The MESA-11 was later merged with the ANSI/ISA-95 (mostly referred to as ISA-95), which was developed by the American National Standards Institute (ANSI) and the International Society of Automation (ISA) to provide an abstract model and terminology for the exchange of information between the enterprise business systems and manufacturing operations systems in a business.

There are five parts to the ISA-95; the basic breakdown is outlined in the diagram below.

How Does a Manufacturing Execution System Work?

MES software connects to machines and equipment on the shop floor so it can gather information about them, and this can happen in many ways, including:

- PLC integration

- Ethernet or wireless connections

- Digital inputs and outputs through sensors wired into the machinery

- Analog signals from legacy equipment

- Utilizing machine interface protocols for process monitoring

A manufacturing execution system guides those on the plant floor step by step through their production tasks to transform raw materials into finished goods. The system manages the workflow and helps to ensure that no errors are made as each product is manufactured. The software actually “talks” to the machines and can program them to handle tasks and update information in the system as production progresses. In addition, employees can see what is happening on a dashboard to oversee the progress.

A manufacturing execution system guides those on the plant floor step by step through their production tasks to transform raw materials into finished goods. The system manages the workflow and helps to ensure that no errors are made as each product is manufactured. The software actually “talks” to the machines and can program them to handle tasks and update information in the system as production progresses. In addition, employees can see what is happening on a dashboard to oversee the progress.

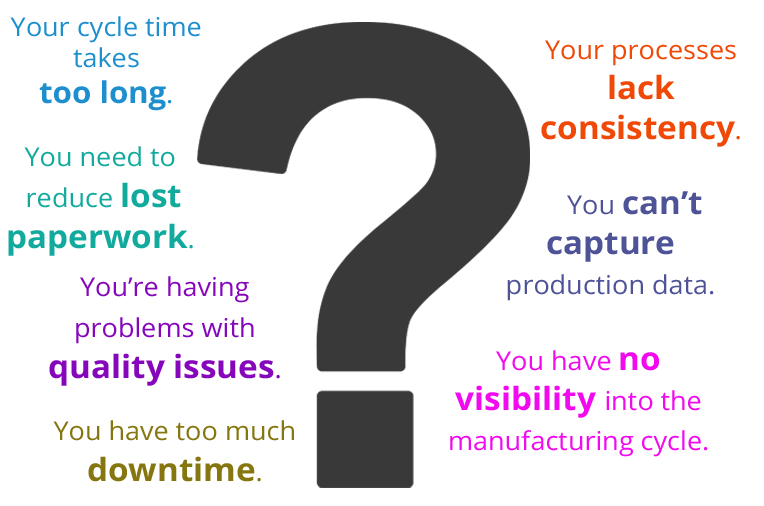

7 Signs You’re Ready for a Manufacturing Execution System

Benefits of Using a Manufacturing Execution System

With a modern manufacturing execution system, you can optimize your shop floor production and have visibility into everything happening across processes. Below is a list of the many benefits gained.

Reduce Errors

With the automation of processes and insight into what is happening with production; you will eliminate errors and intercept problems before they occur.

Increase Productivity

Utilizing the latest technology to connect to machines speeds up production workflow, reducing lead time. As a result, employees are freed up to do more significant tasks.

Decrease Downtime

Receive better information on the production time needed, machine maintenance needs, and real-time visibility to workflow issues to minimize downtime.

Improve Quality

Greater automation and the increased use of technology help to eliminate the opportunity for human error. In addition, built-in failure parameters can be created to identify critical issues and monitor all quality management activities.

Greater Mobility

With modern MES software, plant floor employees can manage tasks away from their workstations, and managers can access in real-time all production-related information to keep workflow optimized.

Competitive Advantage

Using the technology of MES software combined with Industry 4.0 allows you to have a lean plant floor that keeps inventory at optimal levels, production at capacity, errors minimized, costs low, and quality high, all of which help you to compete better.

MES Functionality

A manufacturing execution system offers excellent functionality to keep the plant floor running smoothly. Of course, systems differ, but the MESA-11 noted earlier covers the critical elements of MES software, as shown below.

Operations/Detailed Scheduling

Allows an organization to see in detail everything that is going on with resources so you can plan for an accurate lead time. It helps you look at different possibilities to determine the best way forward. This function includes machine maintenance, inventory levels, and labor so you can decide how to schedule to ensure on-time delivery.

Labor Management

Keeps track and assigns personnel according to their qualifications, how they work, and what needs to be accomplished. In addition, all employee information is tracked regarding time, attendance, setup, etc.; this feature connects with resource allocation to ensure the best assignment.

Resource Allocation & Status

Helps keep track of employees, machinery, tools, and materials to recognize how they can be best utilized. This function also ensures that equipment is set up and operational.

Maintenance Management

Keeps equipment in top performance. A history of maintenance is kept to reference past problems, and regular service is tracked and scheduled to keep the equipment in good working condition.

Dispatching Production Unit

Directs how the workflow is handled to produce products, and its flexibility can accommodate issues that evolve on the plant floor. Dispatching makes sure the best person is assigned to the machine used. It manages customer records, so any notes on their requirements can be considered. Information on customers and their needs can be imported from external databases. Dispatching helps to keep costs down by streamlining operations.

Process Management

The assignment of work on the shop floor based on what needs to be accomplished. Processes are monitored and adjusted automatically, or information is provided to the operators so they can make changes as required. The process management function gathers information from shop floor machines to help determine assignments.

Document Control

Manages any document related to workflow. Examples are design documentation, regulatory information, or ISO corrective action requirements.

Quality Management

Keeps track of information related to product quality and notes any issues with suggestions on how to remedy the situation, determine the cause, and resolve the problem to prevent future issues.

Product Tracking & Genealogy

Monitors all aspects of a product so if there is a problem in the future, you have a history of the product and its components to take corrective measures. This tracking includes supplier(s), employees who worked on the development, equipment used and when it was used, lot numbers, serial numbers, any rework needed, etc.

Data Collection

Gathers and organizes all data around a process to use as a reference regarding operators, machines, materials, and the process.

Performance Analysis

Tracks how well performance on the plant floor measures up to set goals. It analyzes resource utilization and availability, cycle time, conformance to the schedule, and against standards.

Is a Manufacturing Execution System Right for My Business?

A manufacturing execution system can prove invaluable to an organization, mainly if it is highly regulated since traceability helps maintain compliance. The best way to determine if an MES is suitable for your business is to write out your needs and what you want to achieve in the short-term and long-term. Additionally, consider what problems you want to solve so that when you look into MES functionality, you’ll know what you need.

Some small organizations may need help to justify the cost. But, again, it’s a matter of looking at your business to determine if the benefits are worth the investment.

Manufacturing Execution Systems and Enterprise Resource Planning (ERP)

A generic Enterprise Resource Planning (ERP) system handles all essential operations of a business, and a manufacturing-specific ERP provides both business and manufacturing functionality. Some manufacturing ERP systems come with an MES built into them. Or a manufacturing execution system can be integrated with an ERP system. If you already have an ERP system in place, that may be the direction to go, depending on the age of your ERP software. If you’re working on a legacy system, having the two solutions complement each other will be difficult as the MES is working off of new technology, and the ERP will have old functionality.

A generic Enterprise Resource Planning (ERP) system handles all essential operations of a business, and a manufacturing-specific ERP provides both business and manufacturing functionality. Some manufacturing ERP systems come with an MES built into them.

Or a manufacturing execution system can be integrated with an ERP system. If you already have an ERP system in place, that may be the direction to go, depending on the age of your ERP software. If you’re working on a legacy system, having the two solutions complement each other will be difficult as the MES is working off of new technology, and the ERP will have old functionality.

Modern manufacturing ERP systems provide a 360-degree view of your entire manufacturing business and seamlessly integrate core business and manufacturing processes for complete control. Manufacturing ERP manages, automates, tracks, collaborates, and connects every step in a dynamic manufacturing process, from receipt of a customer order to shipment of the order.

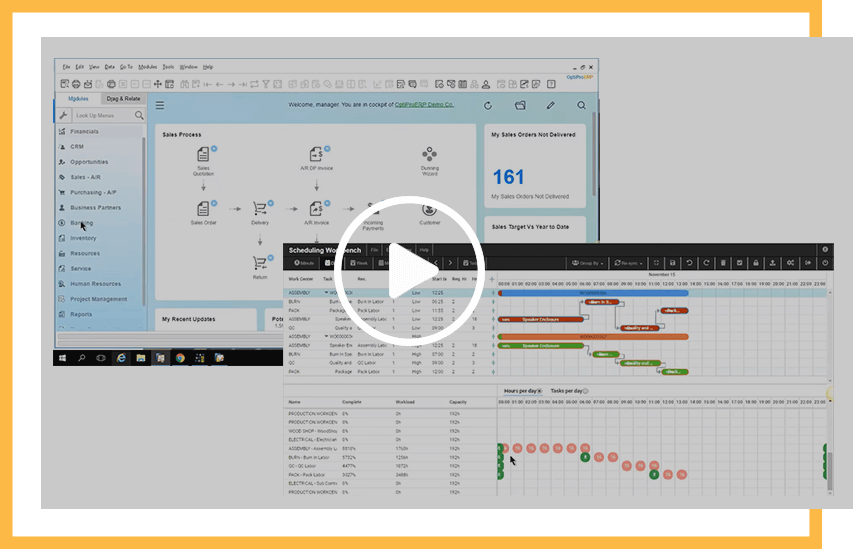

OptiProERP with SAP Business One

OptiProERP is a modern manufacturing ERP that extends the SAP Business One platform to provide a more advanced, fully integrated, and end-to-end solution designed for small to midsize manufacturers and distributors. It allows you to evaluate and optimize your finite manufacturing capacity, manage complex manufacturing schedules, tighten process controls, capture shop floor work order information, and track inventory movements. In addition, OptiProERP’s MES module gathers data directly from operation centers to identify and solve performance issues.

OptiProERP is a modern manufacturing ERP that extends the SAP Business One platform to provide a more advanced, fully integrated, and end-to-end solution designed for small to midsize manufacturers and distributors.

It allows you to evaluate and optimize your finite manufacturing capacity, manage complex manufacturing schedules, tighten process controls, capture shop floor work order information, and track inventory movements. In addition, OptiProERP’s MES module gathers data directly from operation centers to identify and solve performance issues.

See OptiProERP’s Best-of-Breed Solution in Action