Integrates inventory and accounting transactions so stock levels are adjusted, accounts are credited or debited and inventory discrepancies are accounted for.

Inventory Management

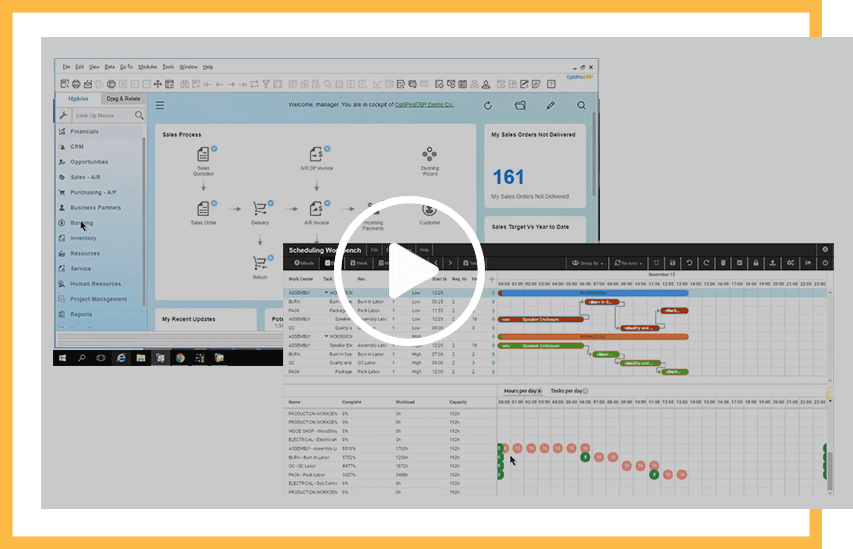

ERP software for manufacturing and distribution

OptiProERP’s Inventory Management software helps your growing business radically reduce inventory carrying costs by giving you full visibility and tracking the movement of inventory from order to delivery in real-time.

OptiProERP’s Inventory Management Software

Inventory Management from OptiProERP will help you succeed in key areas like these:

- Cost reduction: Lower inventory carrying costs.

- Customer retention: Meet customer demand.

- Productivity: Eliminate stock outages.

OptiProERP’s Inventory Management Software

Integrates inventory and accounting transactions so stock levels are adjusted, accounts are credited or debited and inventory discrepancies are accounted for.

Inventory Management from OptiProERP will help you succeed in key areas like these:

- Cost reduction: Lower inventory carrying costs.

- Customer retention: Meet customer demand.

- Productivity: Eliminate stock outages.

Benefits of OptiProERP’s Inventory Management Software

Real-time visibility into safety stock, re-order points, cycle counts and demand planning.

Real-time status on what’s in stock, what’s on order and the due date on every production order.

Real-time synchronization of goods receipts and inventory levels to inform purchasing.

Just-in-Time (JIT) inventory based on sales orders, demand and safety stock minimums.

On-time deliveries while knowing the exact lead time needed for procurement and production.

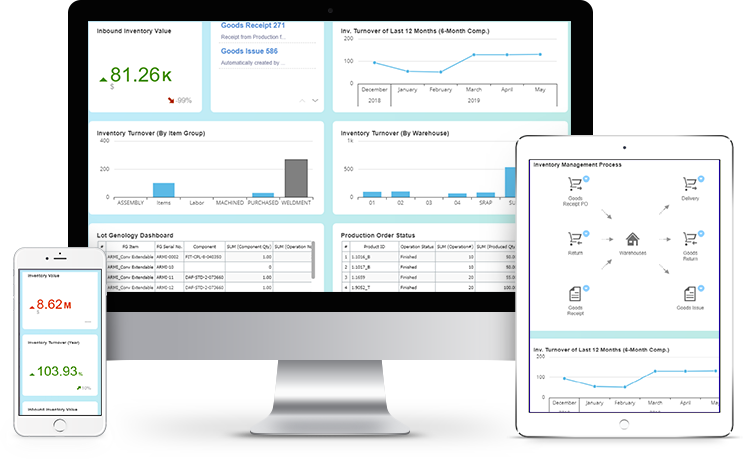

Valuation of in-bound and out-bound inventory, turnover and more on your dashboard.

Easy-to-Use Inventory Management Software from OptiProERP

Mobility matters in today’s 24/7 world

Access the system from anywhere, on any device, tablet or smart phone.

OptiProERP gathers information and populates your personalized, role-based cockpit with everything you need to do your job.

You may see inventory by item or by warehouse. See the location and status of inventory from safety stock to warehouse transfer, WIP, quarantine or shop floor.

Combining convenience and efficiency, inventory professionals may also run and refresh manufacturing and purchasing plans to check for optimal inventory availability.

OptiProERP’s Inventory Management Functionality

Inventory Control

Ensures that the business maintains sufficient stock levels to keep production schedules on track.

Inventory Reports

Maintain minimum stock with real-time reports that forecast demand by hindcasting past buying patterns.

Inventory Audits

Keep track of inventory levels in 3 different ways: physical counting, spot checks and cycle counting.

Direct Drop Shipment

Reduce inventory carrying costs by shipping 3rd party parts or components directly to customers.

ABC Item Analysis

Categorize inventory by highest consumption value, lowest consumption rate and interclass items.

Accurate Forecasting

Forecast inventory requirements accurately with hindcasting based on historical demand.

How OptiProERP’s Inventory Management Software Works

Inventory Management exchanges information with the Master Production Schedule (MPS). Most users use MPS for the things they make, whether it’s made on-site or through a vendor.

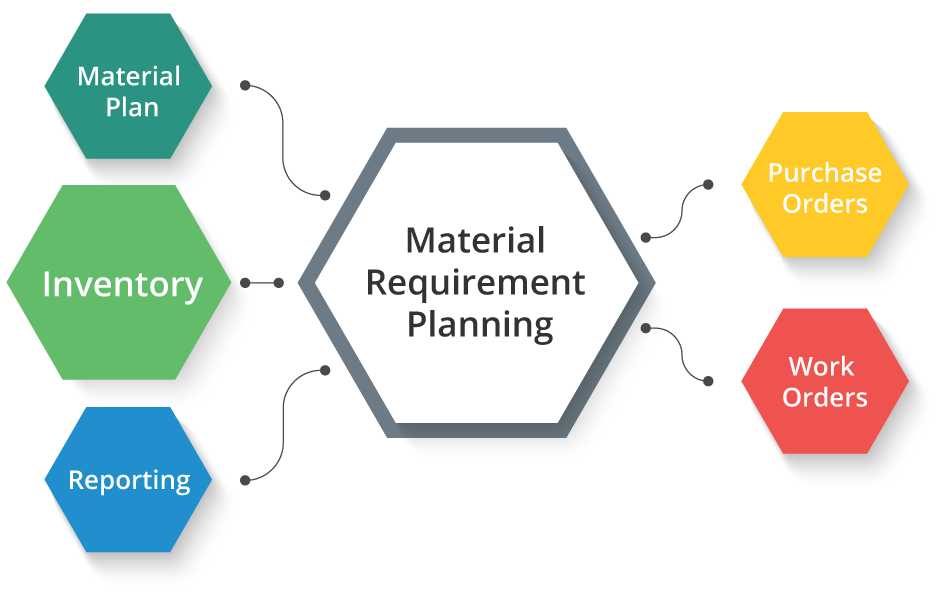

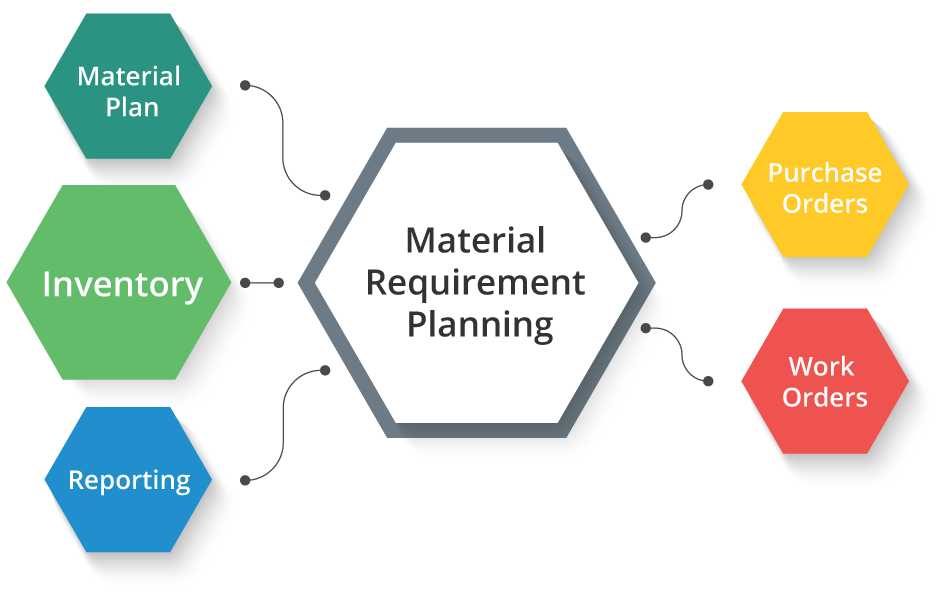

Material Requirements Planning (MRP) receives input from the MPS about the quantities of finished products that must be produced to fulfill either a sales order or to meet the demand forecast. MRP is primarily concerned with the things that must be bought (like inventory). MRP also tracks hundreds of variables, including:

- Purchase orders

- Inventory shortages

- BOMs

- Sales orders

- Priority orders

What OptiProERP’s Inventory Management Software Does

Based on information input from other ERP modules, like Inventory Management, the MRP application produces outcomes like these:

Quantity Requirements: Identifies inventory quantities that are either on hand, in an open purchase order, planned for manufacturing, already committed to existing orders, or forecasted.

Populates Orders and Reports: Identifies materials needed for purchase orders manufacturing orders and other reporting requirements.

Run Scenarios: Suggests alternative scenarios for materials considered critical for an expedited order or materials that have been delayed.

The beauty of this is that all of your procurement schedules are in lock step with your manufacturing or assembly schedules. This enables the cost savings of Just- in-Time (JIT) lean manufacturing with the minimum levels of inventory stock available exactly when it’s needed.

Based on information input from other ERP modules, like Inventory Management, the MRP application produces outcomes like these:

Quantity Requirements: Identifies inventory quantities that are either on hand, in an open purchase order, planned for manufacturing, already committed to existing orders, or forecasted.

Populates Orders and Reports: Identifies materials needed for purchase orders manufacturing orders and other reporting requirements.

Run Scenarios: Suggests alternative scenarios for materials considered critical for an expedited order or materials that have been delayed.

The beauty of this is that all of your procurement schedules are in lock step with your manufacturing or assembly schedules. This enables the cost savings of Just- in-Time (JIT) lean manufacturing with the minimum levels of inventory stock available exactly when it’s needed.

OptiProERP’s Inventory Management Processes

OptiProERP Production Management Data Sheet

Learn more about how OptiProERP’s Production Management software helps you organize, manage and control your production processes.

OptiProERP Production Management Data Sheet

Learn more about how OptiProERP’s Production Management software helps you organize, manage and control your production processes.

The 21st Century ERP Selection Roadmap

Download our free advisory guide with the six things you should consider on your journey to selecting a new ERP solution in today’s digital world.

How to Know if You’re Ready for Inventory Management Software

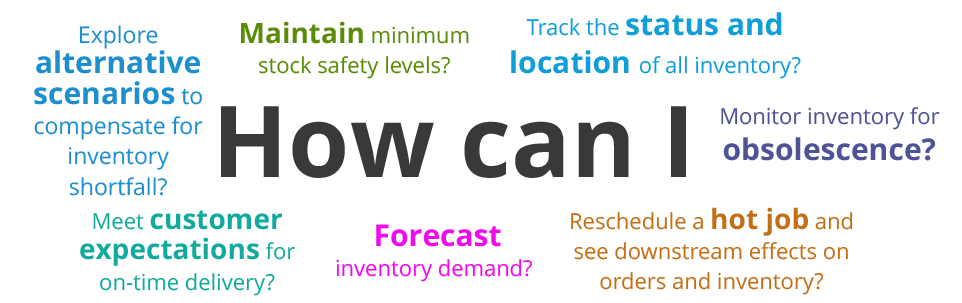

If questions like these are keeping you awake at night, you’re ready for OptiProERP’s end-to-end Inventory Management software.

See how OptiProERP meets your unique needs