In the world of manufacturing and distribution, managing raw materials, work-in-progress, and finished goods often takes center stage. But there’s another critical category of inventory that plays a pivotal role in keeping operations running smoothly: MRO inventory.

MRO stands for Maintenance, Repair, and Operations, and the inventory that falls into this category may not directly become part of the products you sell. Still, it’s essential for day-to-day business continuity. Without it, production lines can stall, machines can break down, and operations can grind to a halt.

In this article, we’ll explain what MRO inventory is, why it matters, and how an ERP system with inventory management capabilities can help streamline MRO processes.

What is MRO Inventory?

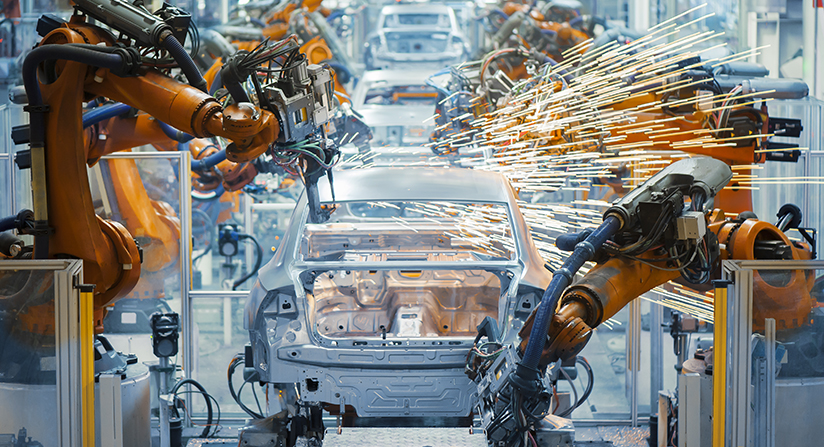

MRO inventory refers to the supplies, tools, and equipment used to support production and facility operations, but that are not part of the finished product. These items are used for maintaining assets, repairing machinery, and ensuring smooth daily operations in manufacturing plants, warehouses, or other industrial facilities.

Common MRO Inventory Examples:

- Spare parts (bearings, belts, gears, valves)

- Tools and equipment (wrenches, torque tools, calibration devices)

- Lubricants and fluids (grease, oils, coolants)

- Safety supplies (gloves, goggles, hard hats)

- Janitorial items (cleaning products, paper towels)

- Office supplies (printer ink, pens, paper)

- Facility maintenance items (light bulbs, air filters, batteries)

While each company’s MRO list varies, all businesses that operate machinery or maintain facilities must manage some level of MRO inventory.

Why is MRO Inventory Management Important?

MRO inventory might not get as much attention as raw materials or finished goods, but it plays a mission-critical role in keeping production and operations on track. Poorly managed MRO inventory can lead to:

1. Production Downtime

If a key machine breaks and you don’t have the required part or tool on hand, production may come to a standstill until the item is sourced. Downtime can be costly—both financially and in terms of lost customer trust.

2. Excessive Costs

Without proper tracking, organizations may overstock MRO items “just in case,” tying up cash in items that sit unused. Alternatively, they may pay premium prices for rush orders when stock runs out unexpectedly.

3. Compliance and Safety Risks

Many industries rely on MRO inventory for compliance with safety and environmental standards. Running out of protective gear or neglecting preventive maintenance can lead to accidents, fines, or regulatory violations.

4. Operational Inefficiencies

Manual tracking or siloed spreadsheets can lead to confusion, duplicate purchases, and lost or misplaced items. This wastes time and reduces productivity.

The Unique Challenges of MRO Inventory

Unlike traditional inventory, MRO items present unique management challenges:

- Unpredictable Usage: It’s challenging to predict when maintenance parts will be required accurately.

- Non-Standard Purchasing Patterns: MRO items are purchased irregularly and often from multiple suppliers.

- Decentralized Storage: MRO inventory is often scattered across different departments, tool cribs, or maintenance closets.

- Risk of Obsolescence: Spare parts may become obsolete if machinery is updated or replaced.

- Accounting Complexities: MRO purchases are typically categorized as indirect expenses, making them harder to track than direct materials.

These factors make MRO inventory management more complex than it initially appears.

How ERP Helps Manage MRO Inventory

An ERP (Enterprise Resource Planning) system with robust inventory management capabilities, such as OptiProERP, helps businesses manage MRO inventory more efficiently and proactively.

Here’s how:

1. Centralized Inventory Tracking

With ERP, MRO inventory is tracked in the same system as production materials, allowing for real-time visibility into stock levels, locations, and usage. This reduces the risk of lost or misplaced items.

2. Preventive Maintenance Planning

Integrating MRO inventory management with maintenance schedules ensures that required parts and tools are available when needed, minimizing unexpected downtime.

3. Automated Replenishment

An ERP system can set reorder points for critical MRO items. When stock levels fall below the threshold, the system automatically triggers a purchase order, preventing shortages.

4. Cost Control

By managing MRO in your ERP, you can analyze historical purchasing data to find opportunities for bulk buying, supplier consolidation, or reducing excess inventory.

5. Compliance Management

ERP systems facilitate the documentation of maintenance activities, calibrations, and part replacements. This can be essential for audits, certifications, and meeting regulatory standards.

6. Reporting and Analytics

Real-time dashboards and reports provide maintenance managers and finance teams with insight into MRO spending, usage trends, and supplier performance, driving better decision-making.

Best Practices for MRO Inventory Management

If your organization is looking to improve its MRO inventory management, consider these best practices:

- Catalog and Standardize: Create a centralized catalog of all MRO items with standardized descriptions and part numbers.

- Integrate with Maintenance Schedules: Tie MRO inventory management to preventive maintenance planning for better forecasting.

- Use Barcoding or RFID: This reduces manual entry errors and speeds up check-in/check-out of tools and parts.

- Regularly Review Inventory Levels: Monitor usage patterns and adjust minimum stock levels as needed.

- Train Your Team: Make sure employees understand the importance of MRO tracking and follow established processes.

- Leverage ERP Tools: Use your ERP system to automate replenishment, manage suppliers, and control costs.

Final Thoughts

MRO inventory may not be glamorous, but it is vital to keeping your operations running. Without properly maintained equipment, tools, and facilities, production comes to a halt.

By adopting an ERP system like OptiProERP, manufacturers and distributors can gain better control over MRO inventory, reduce downtime, cut costs, and improve operational efficiency. Managing MRO effectively is not just a maintenance issue—it’s a strategic advantage.

Learn More

OptiProERP with SAP Business One provides integrated inventory management, maintenance planning, and supply chain tools to help you take control of your MRO processes.

Contact us to discover how we can assist you in streamlining your MRO inventory management.

Follow Us