What Is an Inventory Management System?

Welcome to Manufacturing ERP 101 where you can fast track your understanding of ERP and assess its value to the continued success of your business.

Inventory Defined

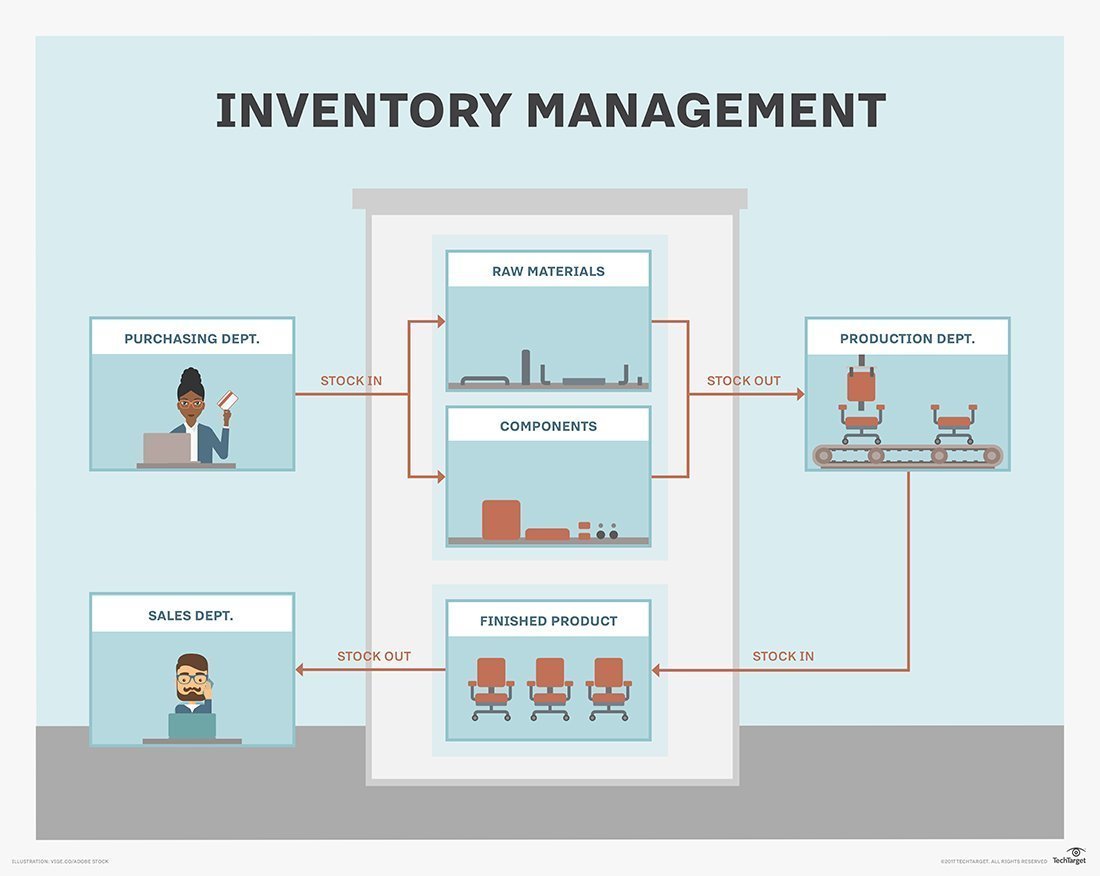

(Before getting into Inventory Management, it’s important to understand what the word ‘inventory’ means). There are three types of inventory to include: Raw Materials, Work in Process, and Finished Goods. Raw Materials are stock used to make an end product. Work in Process consists of the raw materials that are being made into finished goods. And, Finished Goods are the final products that get produced for sale to consumers.

What Is Inventory Management?

Inventory management tracks how much physical inventory you have in your organization. It monitors stock at other locations, such as distributors or subcontractors. When you have clear visibility into your inventory, you know when to order, where to store it, and when you need to stop selling.

Did You Know?

The earliest form of inventory management dates back over 50,000 years when people used “tally sticks” to count. And, approximately 4,000 years ago, clay tokens were used to keep track of livestock.

What is an Inventory Management System?

Managing inventory is an important part of business administration. If you have excess inventory, money is being wasted (which is referred to as underutilization.) If you don’t have enough, it delays deliveries. Neither one is a good scenario.

An inventory management system tracks inventory availability at all points of your supply chain — from purchasing, to production, and finally sales to consumers. An inventory management system is important for companies with large amounts of inventory in order to keep it at optimal levels.

How Does a Modern Inventory Management System Work?

Products get scanned using bar code or RFID (radio frequency identification) systems. This information gets sent to the Inventory Management System to keep track of how much product is being sold and what is in the warehouse.

The system supports electronic data interchange (EDI). EDI sends and receives data between two parties using data transmission lines, i.e. the Internet. It allows communication with vendors to buy materials.

How Does a Modern Inventory Management System Work?

Products get scanned using bar code or RFID (radio frequency identification) systems. This information gets sent to the Inventory Management System to keep track of how much product is being sold and what is in the warehouse.

The system supports electronic data interchange (EDI). EDI sends and receives data between two parties using data transmission lines, i.e. the Internet. It allows communication with vendors to buy materials.

Problems with Traditional Inventory Management

Traditional inventory management becomes problematic as a company grows. It includes supplier agreements to get discounts for consistent orders over specific periods. This often results in ordering more than needed to fulfill production needs. It can also lead to vendor lock-in, obligating you to long-term relationships with suppliers.

Traditional inventory management entails manually checking stock levels to know what is running low. This is time-consuming, prone to errors, and not efficient. To reorder inventory, your purchasing department has to call, email, fax, or use an online system. Again, this uses more employee time than an automated inventory system would.

Warehouses become necessary to store excess inventory. Items that are perishable, hazardous, or require refrigeration need special accommodations. These concerns create additional expense, along with warehouse personnel and theft protection.

Business Intelligence

Pre-delivered information views represent different aspects of your business performance. Use tailored reporting capabilities to analyze the data most relevant to your KPIs.

7 Signs You Are Ready for an Inventory Management System

Why You Need a Modern Inventory Management System

Inventory is a big expense that must be carefully managed. It directly affects your customers — so knowing how much you have on hand at all times is essential. Since inventory levels change constantly, tracking them manually isn’t practical. Modern inventory management systems incorporate new technology to efficiently monitor inventory and manage the supply chain.

Increase Sales

When you have optimal inventory levels, you won’t lose out on missed sales. A modern inventory management system tracks inventory in real time. It allows you to see what is selling well and place orders for more inventory before you run out. You can also set minimum levels to notify you when inventory is getting low and it is time to order.

Scalability

With a modern inventory management system, you no longer rely on manual counts. It helps you keep up with change as your business grows. It keeps track of your stock in all locations and seamlessly integrates with other systems to scale operations.

Reduce Errors

It’s easy for people to miscalculate with manual inventory counts. That can result in too much or too little stock. When processes are automated, there’s less chance for human error. With an inventory management system, scanners can count inventory. The information gets stored for decision-makers to view. It reduces errors and increases efficiency, making inventory tracking faster and more accurate.

Faster Deliveries

Having optimal inventory on hand allows you to fulfill orders on time. No more missing deliveries due to out-of-stock items. Thus, efficient inventory management improves customer satisfaction and retention. You can also add to your customer base with a better brand reputation.

Improved Productivity

With a modern system it's easy to locate items. You can organize your products based on demand for a more streamlined warehouse. With less time looking for things, your workers have more time to spend on activities of greater value for the company. Modern inventory management gives your purchasing department real-time synchronization of inventory receipts and levels. Replenishment orders get placed when needed.

Greater Visibility

Access to real-time inventory levels allows you to spot problems. At a glance you can see your safety stock, re-order points, cycle counts, and demand planning. You can also determine what’s on order and the due date of every production order. It provides analytics, revealing the most profitable products and the best sellers. You can also determine the location or time of year that has the best results.

Reduce Costs

Having too much inventory obliges you to shoulder the cost for items that are not used. Having too little inventory causes you to delay or even cancel customer orders. Either scenario costs your business money. Having the optimal amount of stock means you don’t have the expense of storing items. What is more, you don’t incur labor for manually counting or searching for products.

A modern inventory management system uses AI and machine learning technologies. It makes predictive analysis and demand forecasting more accurate. With this knowledge, you can get better pricing, since you’ll know how much and how often to order.

10 Inventory Management Best Practices for Manufacturers

To achieve the greatest results, it’s important to use best practices as described below.

Incorporate ABC Analysis

ABC Analysis is a method that keeps stock in a hierarchy to make it manageable. “A” items would be the top sellers. “B” would be the next level of priority. The “C” level would be those items that are low-priority and not ordered as often. This method will help keep your inventory organized and streamlined.

Get Your Pick and Pack Process in Order

Pick and pack involves laying out your warehouse for efficiency. Have the most used items closest to where they get packed. Keep the warehouse clean and organized. Double-check each order, and use barcodes or RFIDs on inventory to keep track of levels. If you use a warehouse management system (WMS), pickers are shown exactly where to find items.

Determine Your Inventory KPIs

Key Performance Indicators (KPIs) allow you to track activity and help you make decisions. Inventory carrying cost, write-off and write-down, rate of turnover, cycle time, order status, tracking, and fill rate are KPIs to watch.

Use a Reorder

Point Formula

A reorder point formula defines when to order more inventory. This formula is: (average daily unit sales x average lead time in days) + safety stock = reorder point. Using this formula will help you to keep only the necessary inventory in stock

Maintain Safety Stock

It’s good to keep a small amount of excess inventory. It helps to avoid running out if you have an influx of orders or a change in supplier lead time. Safety stock ensures you don’t lose customers or revenue from being unable to fulfill orders.

Calculate Inventory

Turnover Rate

It’s important to understand how demand affects product turnover. By using a formula, you can know what inventory is not moving and figure out how to get it sold. To calculate inventory turnover, use this formula: Cost of Goods Sold ÷ Average Inventory.

Optimize Inventory Counts

It’s important to optimize the inventory counting process. Schedule inventory counts when it is less likely to interrupt business operations. Make sure everything in the area is clean and organized. Also, know exactly what should get counted to ensure nothing gets missed.

Keep Inventory at a Minimum

It’s important to keep tight control over your inventory. Low inventory reduces holding costs, allows for more space, reduces the risk of product obsolescence, and makes it easy to find items. Keep an eye on which products sell the most and make them easy to access. Review historical records of your safety stock levels to see if you need to make adjustments.

Maintain Good

Vendor Relations

It’s important to have good working relationships with vendors. They are more likely to accommodate you if you run into a problem and need something quickly. Make sure your vendors are paid promptly and maintain good communications with them.

Install a Modern Inventory Management System

An inventory management system is very important to your business. It removes error-prone manual processes and incorporates best practices. It helps improve operations throughout an organization.

Inventory Management System Functionality

Inventory management systems have many features, but the most common are below.

Control

Inventory control keeps track of items on the warehouse floor. It categorizes by type, location, and SKU. This helps to audit data, to generate reports, and to search, filter, and view products.

Management

Handles administrative functions and integrates with other software if needed.

Tracking

Inventory tracking keeps tabs on orders in transit, giving you end-to-end visibility into your supply chain. It integrates with your suppliers’ systems to automatically reorder items when supplies are low. It allows customers to receive information on what products are available and when.

Barcoding

To make it quick and easy to track, the software integrates with barcode scanners to identify and label products.

Optimization

This part of the system allows you to take control of your inventory needs. It provides automated reports that show trends and changes to the supply chain. It keeps exactly the right amount of inventory on hand.

Alerts

Receive alerts when inventory falls below or rises above predefined levels. If there is a delay anywhere along the supply chain there is also a trigger. Having these notifications lets you reduce waste, manage costs, and keep customers informed.

Modern Inventory Management System Features

To get the most from an inventory management system, consider the following features. They will allow your business to compete in today’s fast-changing marketplace.

Cloud-Based

When you run on a cloud-based system, you do not have to use in-house resources to manage the software. The vendor provides support, automatic updates, and robust security. It scales as you grow and is less expensive than the up-front cost of an on-premises system.

IoT Integration

It’s important to be able to use the technology that is at your disposal. Internet of Things (IoT) integration provides greater control and better reporting. It also allows digital labeling and tracking through GPS, Bluetooth, and RFID.

Mobile

Staff can use mobile devices to provide and receive real-time information on the go. Mobility provides greater efficiency and faster response times.

Demand Forecasting

Forecasting uses your sales and production history to predict demand. It helps with decisions on reordering inventory, scheduling staff for production, and whether to hire more staff.

E-Commerce Integration

If you sell direct to consumers – or even business to business (B2B) – this is a very useful feature. E-commerce connects inventory management to online orders to keep stock current.

Machine Learning

and AI

Interact with e-commerce customers using chatbots powered by AI. They can provide information on product availability. Machine learning helps chatbots know what is in stock, or what a customer may like based on their purchasing history. This technology also helps better track and forecast inventory.

On-premise

On-premise warehouse management systems require more internal resources to support and maintain. It is installed on the company’s native hardware and network. Many companies prefer this method as it gives them greater control.

Cloud-based

A cloud-based system does not require server hardware or synchronization with server hardware and networks as it is web-based. It is quicker to implement, easier to upgrade, simpler to use, and can scale with your business.

Choosing an Inventory Management System

The best way to know what your business needs from an inventory management system is to identify your problem areas. Once you have this information, it is easier to know what functionality you’ll need as you look for systems.

There are lots of inventory management systems on the market. Will you need to connect to other existing systems? If so, you’ll want to ask vendors if their system can integrate. You’ll also want to learn what’s involved with the transition, how the vendor will assist you in the change from manual to automated processes, and what level of training is offered.

You’ll want to understand all of the costs involved in implementing the new software. Make sure it can handle what you currently process while having plenty of room for growth. If you are connecting systems, your in-house IT will need to manage updates to ensure the systems continue to work together. Be sure your IT staff has the capability.

Determine any hardware costs, user fees, and upgrade or maintenance costs. Find out how much training they provide.

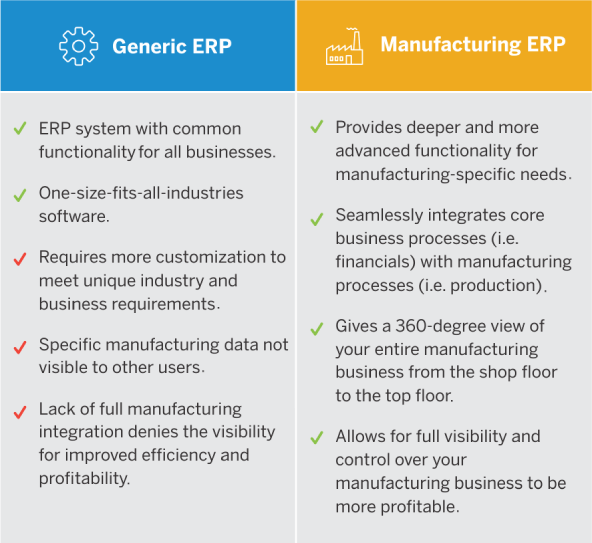

Modern ERP With Inventory Management

If you are looking to integrate many systems, it may make sense to consider an Enterprise Resource Planning (ERP) solution. An ERP system integrates all aspects of your operation – from planning to production to purchasing. Instead of connecting several different systems, you use one system and database. That way, you can manage your entire operation and optimize your inventory.

The most common ERP modules are Human Resources, Inventory, Sales/Marketing, CRM, Purchasing, and Finance/Accounting. ERP helps companies unify critical business functions and optimize operations. Its organization-wide visibility helps detect inefficient processes and reveals growth opportunities.

Manufacturing ERP delivers manufacturing-specific functionalities that streamline and automate core business and manufacturing processes. Modern manufacturing ERPs are built into the same databases that run everyday business processes and applications, creating a complete business management platform.

Budget/ROI

Review the gains you will receive from a warehouse management system to help you determine your budget. You should receive a return on your investment in the form of:

- Improved processes and efficiency (doing more with fewer resources)

- Reduced costs from efficiency gains and better inventory management

- Better customer service for increased customer retention and revenue

- Improved accuracy resulting in less re-work and better decision making

- Increased visibility and traceability

- Increased productivity

- Better space utilization

Functionality

Look for systems that will perform the functions most important to your organization. Some of the essentials you’ll want are:

- Real-time inventory movement tracking

- Improved labor, equipment, and space utilization

- Greater picking, packing, and dispatch accuracy

- Better insight into operations

- Up-to-date technology that includes barcoding, RFID, serialization, mobility, etc.

Vendors

- Look into vendors and solutions that will best suit your needs and budget. Consider the following:

- Do they have expertise in your industry?

- Is their WMS an add-on or fully integrated with their ERP solution?

- How are upgrades handled?

- Are they responsive and helpful?

- Is customization needed?

- What is their training process?

- Create a Request for Information (RFI).

- Describe your business

- Outline your future business plans

- Explain what you hope to achieve with the WMS

- Provide information about your warehouse volume

- Request implementation time frames

- Ask how long before you will see ROI or time to value

- Ask about their company to include:

- History

- Functionality

- Similar customers

- Number of locations using their WMS

- Future development and product roadmap plans

- Support

- Successes

- Create a shortlist of vendors/solutions you prefer

- View demos, presentations, videos, etc. to understand how their solutions work

- Get and negotiate pricing proposals

- Check references

- Select your solution!

Why OptiProERP?

OptiProERP was founded with the vision to solve the 21st century problems manufacturers face by reinventing ageing 20th century ERP.

The problem with 20th century ERP is the layering of new functionality on top of an old ERP platforms resulting in:

- Slow system performance.

- Multiple screens and clicks to access job-relevant data.

- Not-so-seamless integration between financial data and plant floor operations.

A Platform Play for OptiProERP with SAP Business One

OptiProERP chose SAP Business One, the #1 ERP platform for small and midsize businesses, for its ERP platform.

With SAP’s continuous platform innovation, we focused exclusively on innovating and developing our industry-specific manufacturing functionality.

This decision freed OptiProERP from the recurring cycle of platform updates that most ERP providers cannot keep current. Unlike SAP Business One, that invests more in research and development than all of the other ERP providers combined, OptiProERP could focus all of its resources into building advanced manufacturing functionality on a truly modern platform.

Instead of adding a layer of code on top of SAP Business One, OptiProERP is built into the DNA of SAP’s trusted ERP platform. The two perform as one because at the code level, they are one.

The result is a 21st century solution designed to help growing manufacturers gain full visibility and control of their business, reduce production costs, increase profit margins and leverage data to inform intelligent business decisions.

Innovative Manufacturing ERP With Inventory Management

OptiProERP is a complete manufacturing ERP solution embedded into SAP Business One. It provides business and manufacturing functionality, including robust inventory management features. OptiProERP is mobile-friendly and cloud-based. It provides demand forecasting, IoT integration, machine learning, and AI. OptiProERP also includes e-commerce and warehouse management modules.

Get a Fully Integrated Financial Management System and Manufacturing ERP Solution with OptiProERP

Manufacturers need full integration between their accounting department and their purchasing and manufacturing operations in order to run a truly efficient organization. OptiProERP, an ERP system specific to the manufacturing industry, has strong accounting and financials as well as shop floor execution, inventory management, and job costing. Get immediate access to both financial and shop floor data to help you have shorter production runs, keep up with product changes, and deliver a personalized customer experience.

OptiProERP is built on SAP Business One, the market-leading platform for small and midsize enterprises. It extends the platform to provide a more advanced, fully integrated, end-to-end solution designed specifically for manufacturers.

What Our Customers Say About OptiProERP

Manufacturing companies like you are investing in their future and they are putting their trust in 21st century ERP from OptiProERP.

SITUATION

After 15 years of steady growth, DACSA (Design, Automation and Centrifuges), a manufacturing business that modernizes sugar centrifuges in the sugar mills of Mexico, had outgrown the manual processes they used to run the business.

SOLUTION

DACSA needed advanced manufacturing functionality to help them fully cost the products they were delivering, including sub-contracted services. They also needed the ability to manage parallel processing in order to meet delivery deadlines.

VALUE

DACSA relies on OptiProERP to standardize processes, define distribution channels and automate manufacturing processes. Focused on continued growth, DACSA relies on the continuous quality system checks from OptiProERP to meet their aggressive goals.

Need assistance with your ERP selection process? Schedule a brief product tour with an OptiProERP manufacturing advisor today!

See More of OptiProERP with SAP Business One in Action