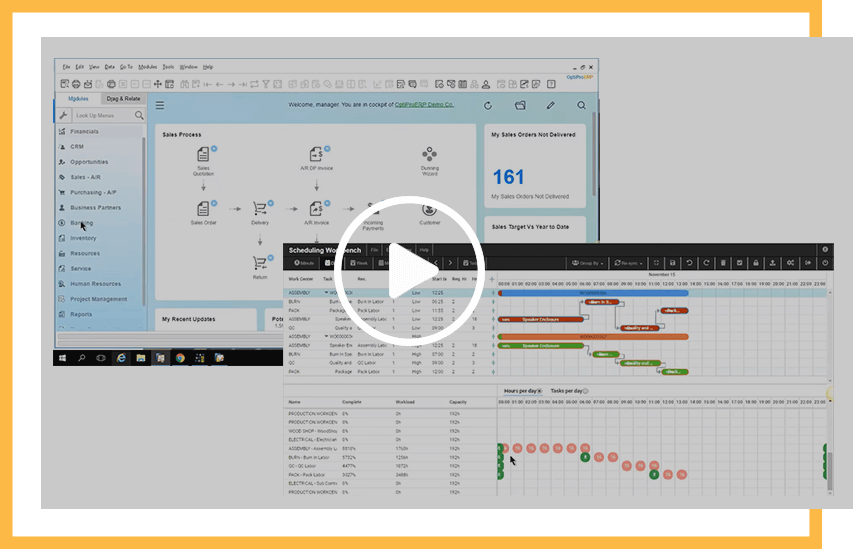

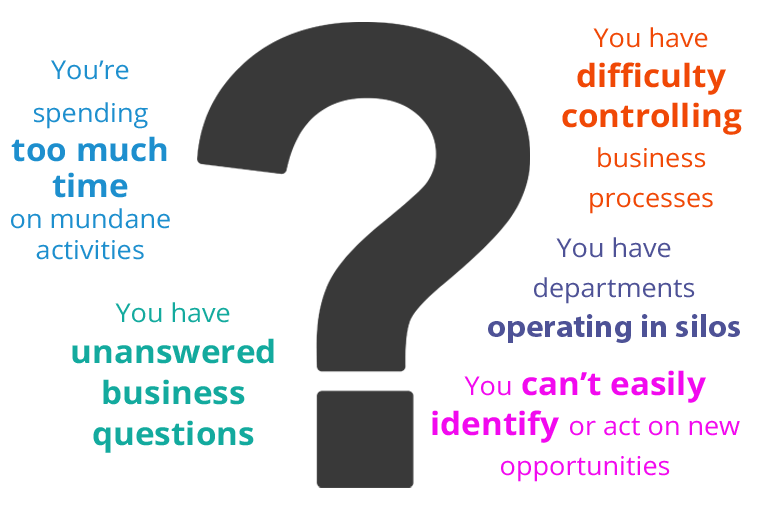

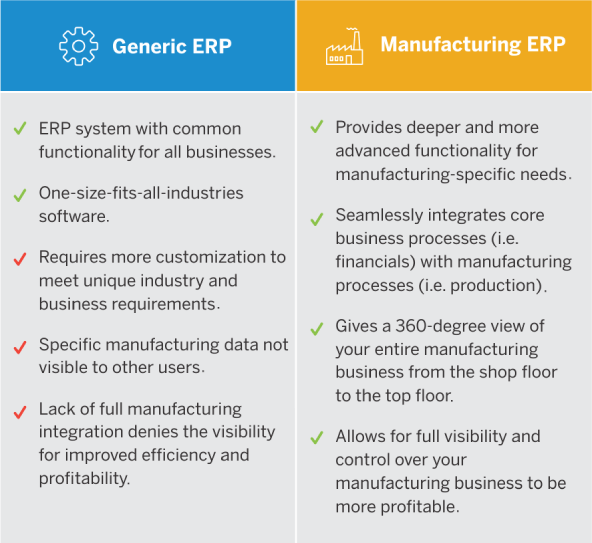

ERP stands for Enterprise Resource Planning. An ERP system brings all core business processes into one database and integrates these processes into a single system to deliver a connected business. A connected business platform allows companies to coordinate activities and processes across business functions from one central place, have one system of record (a single source of truth), and run a true end-to-end organization.

Xiris eliminates siloed data and operational inefficiencies

“The advantages Xiris found with OptiProERP were that it had the strongest MRP module of those we evaluated, and had superior production scheduling. Its fully-featured CRM module was superior to Epicor and all the others.”

Maxim Fisun

Financial Controller